Copper conductors provide superior electrical conductivity and are more resistant to corrosion compared to aluminum conductors, making them ideal for high-performance applications. Copper's higher tensile strength allows for smaller diameter wires with better durability and longevity, reducing maintenance and replacement costs over time. Although aluminum conductors are lighter and more cost-effective, their lower conductivity and tendency to expand and contract can lead to connection issues in critical electrical systems.

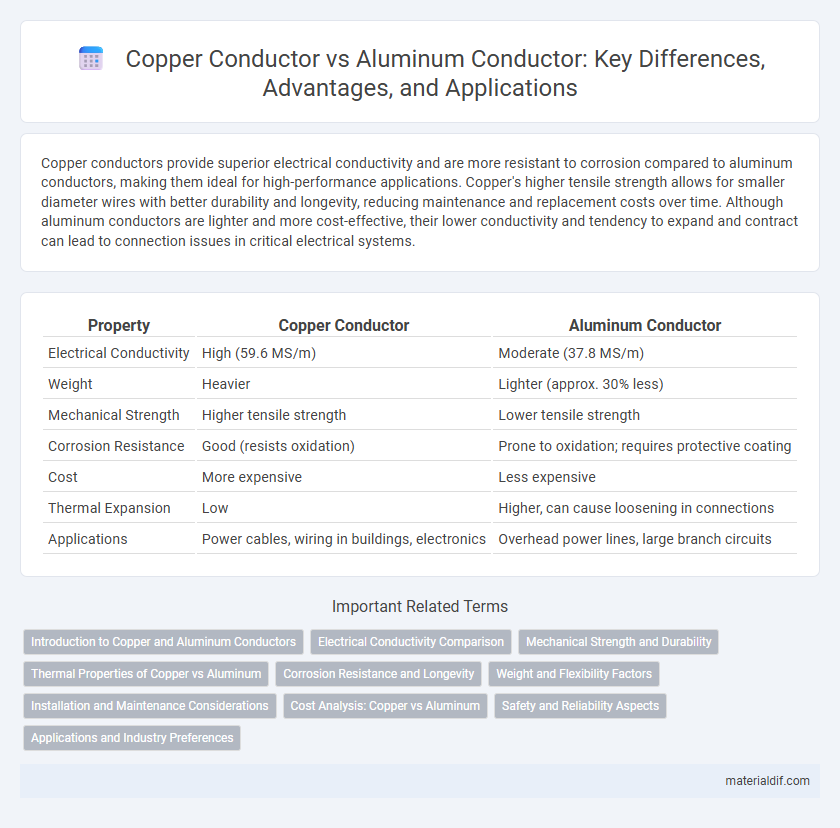

Table of Comparison

| Property | Copper Conductor | Aluminum Conductor |

|---|---|---|

| Electrical Conductivity | High (59.6 MS/m) | Moderate (37.8 MS/m) |

| Weight | Heavier | Lighter (approx. 30% less) |

| Mechanical Strength | Higher tensile strength | Lower tensile strength |

| Corrosion Resistance | Good (resists oxidation) | Prone to oxidation; requires protective coating |

| Cost | More expensive | Less expensive |

| Thermal Expansion | Low | Higher, can cause loosening in connections |

| Applications | Power cables, wiring in buildings, electronics | Overhead power lines, large branch circuits |

Introduction to Copper and Aluminum Conductors

Copper conductors offer superior electrical conductivity and durability compared to aluminum conductors, making them ideal for high-performance electrical wiring. Aluminum conductors provide a lightweight and cost-effective alternative, often used in large-scale power transmission and distribution systems. Both materials require careful consideration of conductivity, tensile strength, and thermal expansion properties to ensure efficient and safe electrical installations.

Electrical Conductivity Comparison

Copper conductors exhibit higher electrical conductivity, approximately 5.96 x 10^7 S/m, compared to aluminum conductors, which have conductivity around 3.5 x 10^7 S/m. This superior conductivity allows copper to carry more current with less resistance and reduced energy loss. The enhanced efficiency of copper conductors makes them ideal for applications requiring reliable and consistent electrical performance.

Mechanical Strength and Durability

Copper conductors exhibit superior mechanical strength and durability compared to aluminum conductors, making them more resistant to mechanical stress and deformation. Copper's higher tensile strength and fatigue resistance result in longer service life and reduced likelihood of breakage under load conditions. Aluminum conductors, while lighter, are more prone to creep and oxidation, which can compromise their structural integrity over time.

Thermal Properties of Copper vs Aluminum

Copper conductors exhibit superior thermal conductivity, approximately 401 W/m*K, compared to aluminum's 237 W/m*K, enabling more efficient heat dissipation and reduced risk of overheating. The higher melting point of copper, around 1085degC, provides enhanced thermal stability under high-temperature conditions. These thermal properties contribute to copper's reliability in electrical applications requiring sustained high current loads and minimal thermal expansion.

Corrosion Resistance and Longevity

Copper conductors exhibit superior corrosion resistance compared to aluminum conductors due to their stable oxide layer, which prevents further degradation and enhances longevity. Aluminum conductors are prone to oxidation and galvanic corrosion, leading to increased maintenance and potential failure over time. Copper's durability and resistance to environmental factors result in a longer lifespan, making it a preferred choice for critical electrical applications.

Weight and Flexibility Factors

Copper conductors are denser and heavier than aluminum conductors, impacting overall wiring weight in large installations. Copper offers superior flexibility due to its lower modulus of elasticity, allowing easier bending and installation in tight spaces. Aluminum conductors, while lighter and less flexible, require larger cross-sectional areas to match copper's conductivity, influencing weight and handling characteristics.

Installation and Maintenance Considerations

Copper conductor offers superior conductivity and durability compared to aluminum conductor, resulting in easier installation with fewer connection issues. Copper's resistance to oxidation minimizes maintenance needs, while aluminum requires periodic inspection and tightening due to its tendency to expand and contract. Installation of copper conductors demands less precaution against thermal expansion, reducing potential long-term maintenance costs.

Cost Analysis: Copper vs Aluminum

Copper conductors generally have higher material costs than aluminum but offer superior electrical conductivity and durability. Aluminum conductors are more cost-effective upfront due to lower raw material prices and lighter weight, reducing installation expenses in large-scale projects. Long-term cost analysis must consider maintenance, lifespan, and efficiency, where copper often results in lower overall costs despite the initial premium.

Safety and Reliability Aspects

Copper conductors offer superior safety and reliability compared to aluminum due to their higher tensile strength, better conductivity, and resistance to corrosion, which reduces the risk of overheating and fire hazards. Copper's stable thermal expansion minimizes loosening at connections, ensuring consistent electrical contact and reducing maintenance needs. Aluminum conductors, while lighter and cost-effective, are more prone to oxidation and mechanical fatigue, potentially compromising long-term safety and reliability in electrical systems.

Applications and Industry Preferences

Copper conductors are preferred in electrical wiring for residential, commercial, and industrial applications due to their superior conductivity, durability, and resistance to corrosion compared to aluminum conductors. Aluminum conductors find extensive use in power distribution and overhead transmission lines because of their lighter weight and cost-effectiveness, making them suitable for large-scale infrastructure projects. Industry preferences lean towards copper for critical applications requiring high reliability and efficient current flow, while aluminum is favored where budget constraints and weight reduction are priorities.

Copper Conductor vs Aluminum Conductor Infographic

materialdif.com

materialdif.com