Copper tubing offers flexibility and ease of installation for plumbing and HVAC applications, while copper rod provides superior strength and is often used in electrical wiring and construction. The hollow structure of copper tubing allows for efficient fluid transport, whereas the solid copper rod delivers robust mechanical support. Choosing between the two depends on whether the application prioritizes fluid flow or structural integrity.

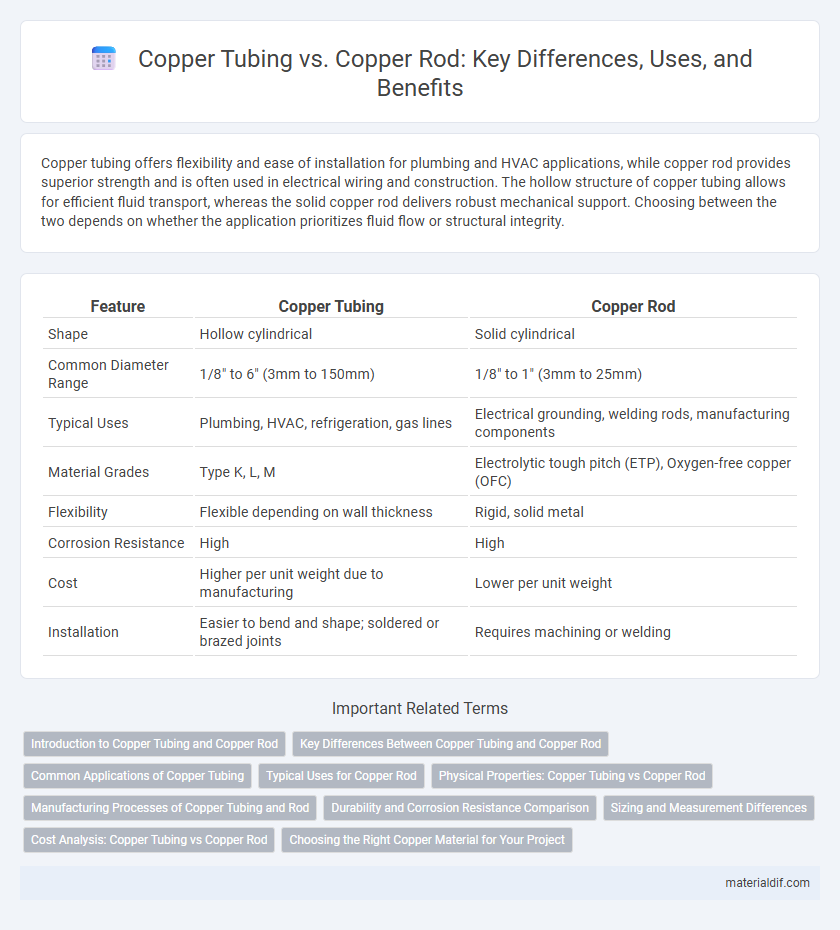

Table of Comparison

| Feature | Copper Tubing | Copper Rod |

|---|---|---|

| Shape | Hollow cylindrical | Solid cylindrical |

| Common Diameter Range | 1/8" to 6" (3mm to 150mm) | 1/8" to 1" (3mm to 25mm) |

| Typical Uses | Plumbing, HVAC, refrigeration, gas lines | Electrical grounding, welding rods, manufacturing components |

| Material Grades | Type K, L, M | Electrolytic tough pitch (ETP), Oxygen-free copper (OFC) |

| Flexibility | Flexible depending on wall thickness | Rigid, solid metal |

| Corrosion Resistance | High | High |

| Cost | Higher per unit weight due to manufacturing | Lower per unit weight |

| Installation | Easier to bend and shape; soldered or brazed joints | Requires machining or welding |

Introduction to Copper Tubing and Copper Rod

Copper tubing is a versatile cylindrical hollow pipe used primarily for plumbing, HVAC systems, and fluid transfer due to its excellent corrosion resistance and thermal conductivity. Copper rods are solid cylindrical bars often employed in electrical wiring, construction, and manufacturing components because of their high electrical conductivity and mechanical strength. Understanding the distinctions between copper tubing and copper rod is essential for selecting the right material based on application requirements involving durability, flexibility, and conductivity.

Key Differences Between Copper Tubing and Copper Rod

Copper tubing is hollow and primarily used for plumbing, HVAC systems, and fluid transport due to its flexibility and ease of installation, whereas copper rod is solid and typically utilized in electrical applications, manufacturing, and construction where strength and conductivity are essential. The key differences lie in their physical structure--tubing's hollow cylindrical form versus rod's solid cylindrical shape--and their distinct functional applications based on these structural characteristics. Copper tubing often meets ASTM B88 standards for water delivery, while copper rods adhere to ASTM B170 standards for electrical and industrial uses.

Common Applications of Copper Tubing

Copper tubing is predominantly used in plumbing, HVAC systems, and refrigeration due to its excellent thermal conductivity and corrosion resistance. It facilitates water supply lines, gas lines, and coolant circulation, ensuring durability and safe transportation of fluids. Unlike copper rod, which is primarily used in electrical wiring and manufacturing, copper tubing is specifically designed for fluid transfer applications.

Typical Uses for Copper Rod

Copper rod is primarily used in electrical applications such as wiring, bus bars, and motor windings due to its excellent conductivity and flexibility. It is also essential in manufacturing fasteners, hardware components, and plumbing fittings where high strength and corrosion resistance are required. Unlike copper tubing, which is designed for fluid transport and HVAC systems, copper rod serves as a versatile raw material for machining and fabrication processes.

Physical Properties: Copper Tubing vs Copper Rod

Copper tubing exhibits greater flexibility and hollow structure, making it ideal for plumbing and HVAC applications, while copper rod offers superior rigidity and solid composition suited for electrical wiring and machining. The thermal conductivity of copper tubing facilitates efficient heat transfer in cooling systems, whereas copper rod's higher tensile strength provides durability for structural and industrial uses. Both forms maintain excellent corrosion resistance, but their physical variations dictate specific suitability across mechanical and electrical engineering fields.

Manufacturing Processes of Copper Tubing and Rod

Copper tubing is manufactured through a process called extrusion or rotary piercing combined with drawing, which shapes heated copper billets into hollow tubes by forcing the material through a die or piercing it to create a lumen, followed by multiple drawing and annealing steps to achieve precise dimensions and enhanced mechanical properties. Copper rods are produced by continuous casting or direct hot extrusion of molten copper, followed by hot and cold rolling or drawing to attain the required diameter and surface finish, with annealing applied to control hardness and ductility. The manufacturing of copper tubing involves more complex shaping steps to create hollow profiles, whereas copper rod production focuses on solid, cylindrical forms optimized for conductivity and fabrication.

Durability and Corrosion Resistance Comparison

Copper tubing offers excellent durability and superior corrosion resistance due to its seamless manufacturing process and uniform wall thickness, making it ideal for plumbing and HVAC systems exposed to moisture and temperature fluctuations. Copper rods, while strong and suitable for structural applications, typically exhibit less corrosion resistance because of their solid, non-hollow structure, which can be more prone to oxidation over time. The superior corrosion resistance of copper tubing extends its lifespan in harsh environments, ensuring reliable performance and reduced maintenance costs compared to copper rods.

Sizing and Measurement Differences

Copper tubing is typically measured by its outside diameter (OD) and wall thickness, making it suitable for applications requiring precise fluid flow and pressure control. Copper rods are sized by their diameter only, reflecting their solid, cylindrical shape used primarily in electrical and construction contexts. The sizing difference is crucial since tubing is hollow for fluid transport, while rods provide structural support or conductivity without internal passage.

Cost Analysis: Copper Tubing vs Copper Rod

Copper tubing generally costs more per linear foot than copper rod due to its manufacturing complexity and flexibility requirements in plumbing and HVAC systems. Copper rods, primarily used in electrical and industrial applications, often present a lower initial material cost but may incur additional expenses for bending and shaping. Cost analysis must consider long-term durability and application-specific factors such as installation labor and maintenance when choosing between copper tubing and copper rod.

Choosing the Right Copper Material for Your Project

Copper tubing offers superior flexibility and corrosion resistance, making it ideal for plumbing and HVAC applications where bending and joining are required. Copper rod provides enhanced strength and machinability, suited for manufacturing and construction projects demanding structural support or precision shaping. Selecting the right copper material depends on balancing the need for durability, malleability, and intended use in your specific project.

Copper Tubing vs Copper Rod Infographic

materialdif.com

materialdif.com