Copper plating involves depositing a thin layer of copper onto a surface using an electrochemical process, enhancing conductivity and corrosion resistance. Copper etching selectively removes copper from a substrate through chemical reactions, creating precise patterns for electronic circuits and decorative designs. Both techniques are crucial in PCB manufacturing, but plating builds up copper layers, whereas etching subtracts from existing copper.

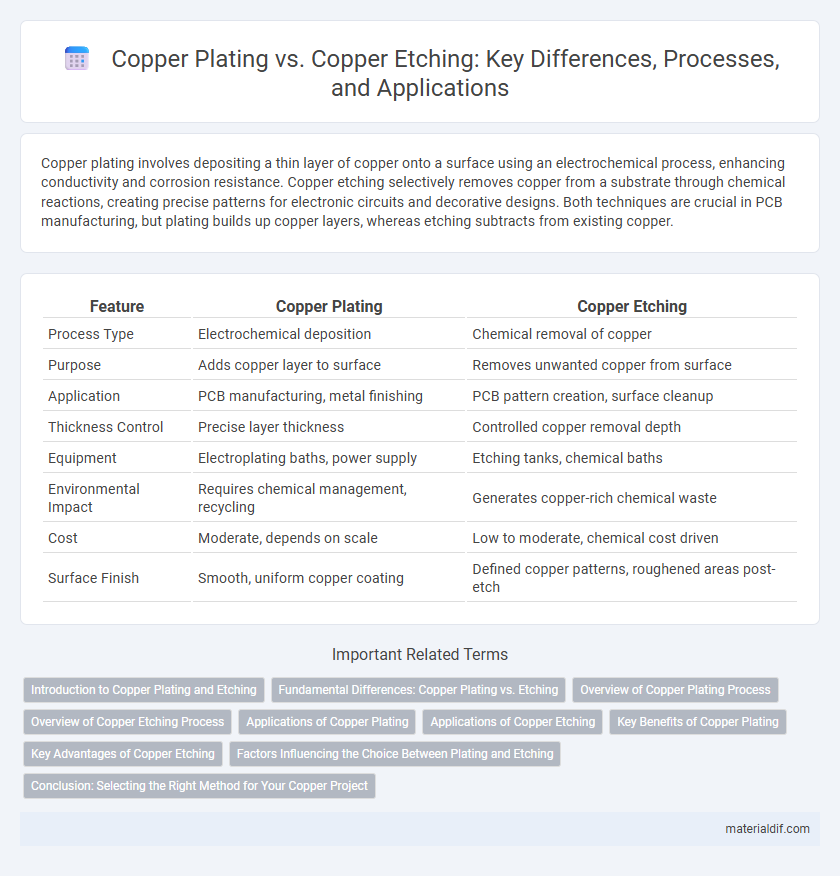

Table of Comparison

| Feature | Copper Plating | Copper Etching |

|---|---|---|

| Process Type | Electrochemical deposition | Chemical removal of copper |

| Purpose | Adds copper layer to surface | Removes unwanted copper from surface |

| Application | PCB manufacturing, metal finishing | PCB pattern creation, surface cleanup |

| Thickness Control | Precise layer thickness | Controlled copper removal depth |

| Equipment | Electroplating baths, power supply | Etching tanks, chemical baths |

| Environmental Impact | Requires chemical management, recycling | Generates copper-rich chemical waste |

| Cost | Moderate, depends on scale | Low to moderate, chemical cost driven |

| Surface Finish | Smooth, uniform copper coating | Defined copper patterns, roughened areas post-etch |

Introduction to Copper Plating and Etching

Copper plating involves depositing a thin layer of copper onto a surface through electrochemical processes, enhancing conductivity and corrosion resistance. Copper etching uses chemical solutions or laser techniques to selectively remove copper from a substrate, creating detailed patterns or circuit designs. Both methods are essential in electronics manufacturing, but plating adds material while etching subtracts it for precise component fabrication.

Fundamental Differences: Copper Plating vs. Etching

Copper plating involves depositing a thin layer of copper onto a substrate through electrochemical processes, enhancing corrosion resistance and electrical conductivity. Copper etching, by contrast, removes copper selectively from a surface using chemical or laser methods to create precise patterns or circuits. The fundamental difference lies in plating adding copper material for coating, while etching subtracts copper to form designs or pathways.

Overview of Copper Plating Process

The copper plating process involves depositing a thin layer of copper onto a conductive surface through electrochemical deposition, enhancing conductivity and corrosion resistance. This method requires a copper sulfate electrolyte solution, anodes made of pure copper, and precise control of current density to ensure uniform coating. Copper plating is widely used in electronics manufacturing, decorative finishes, and industrial applications due to its ability to improve surface properties and extend component lifespan.

Overview of Copper Etching Process

Copper etching involves using chemical solutions, such as ferric chloride or ammonium persulfate, to selectively remove copper from a substrate, creating precise patterns or circuits. This subtractive process enables detailed designs on printed circuit boards (PCBs) by dissolving unwanted copper while preserving the desired areas protected by a resist. Compared to copper plating, etching offers high-resolution control and is essential in manufacturing electronic components where accuracy and fine features are critical.

Applications of Copper Plating

Copper plating is widely used in electronics manufacturing due to its excellent electrical conductivity and corrosion resistance, making it ideal for printed circuit boards (PCBs) and semiconductor components. It also enhances the durability and aesthetic appeal of automotive parts, plumbing fixtures, and decorative hardware by providing a uniform, adhesive metallic layer. Industrial applications benefit from copper plating in improving wear resistance and thermal conductivity in heat exchangers and industrial machinery.

Applications of Copper Etching

Copper etching is widely used in the manufacturing of printed circuit boards (PCBs) due to its precision in creating fine conductive pathways. It enables intricate designs and controlled removal of unwanted copper layers, essential for electronic components and microfabrication. This process is also critical in decorative arts and metal surface patterning, providing high detail and durability for industrial and artistic applications.

Key Benefits of Copper Plating

Copper plating provides a durable, corrosion-resistant surface that enhances electrical conductivity and improves solderability, making it ideal for electronic components and circuit boards. It allows precise thickness control and uniform coverage on complex geometries, ensuring consistent performance and longevity. Unlike copper etching, copper plating reduces material waste and offers superior adhesion for subsequent layers or coatings.

Key Advantages of Copper Etching

Copper etching offers precise material removal, enabling intricate circuit patterns essential for advanced electronics manufacturing. This process reduces waste by selectively targeting unwanted copper, enhancing cost-efficiency compared to copper plating. High accuracy in copper etching also improves product reliability and allows better control over layer thickness in printed circuit boards.

Factors Influencing the Choice Between Plating and Etching

Copper plating offers enhanced corrosion resistance and improved electrical conductivity, making it ideal for applications requiring durable surface coatings. Copper etching provides precise patterning and fine detail removal, suitable for creating intricate circuit designs or decorative finishes. The decision between plating and etching depends on factors such as desired surface thickness, level of precision, application purpose, and cost considerations.

Conclusion: Selecting the Right Method for Your Copper Project

Choosing between copper plating and copper etching depends on the project's precision and application requirements. Copper plating offers a durable, conductive coating ideal for electronic components, while copper etching excels in creating intricate patterns for printed circuit boards and decorative finishes. Understanding the specific needs, such as thickness, detail, and conductivity, ensures optimal results for copper-based manufacturing or artistic endeavors.

Copper Plating vs Copper Etching Infographic

materialdif.com

materialdif.com