Copper offers superior electrical conductivity and corrosion resistance compared to tin, making it ideal for electrical wiring and plumbing applications. While tin is softer and more malleable, it is primarily used as a protective coating for other metals to prevent corrosion. The combination of copper and tin creates bronze, an alloy valued for its hardness and durability in tools and sculptures.

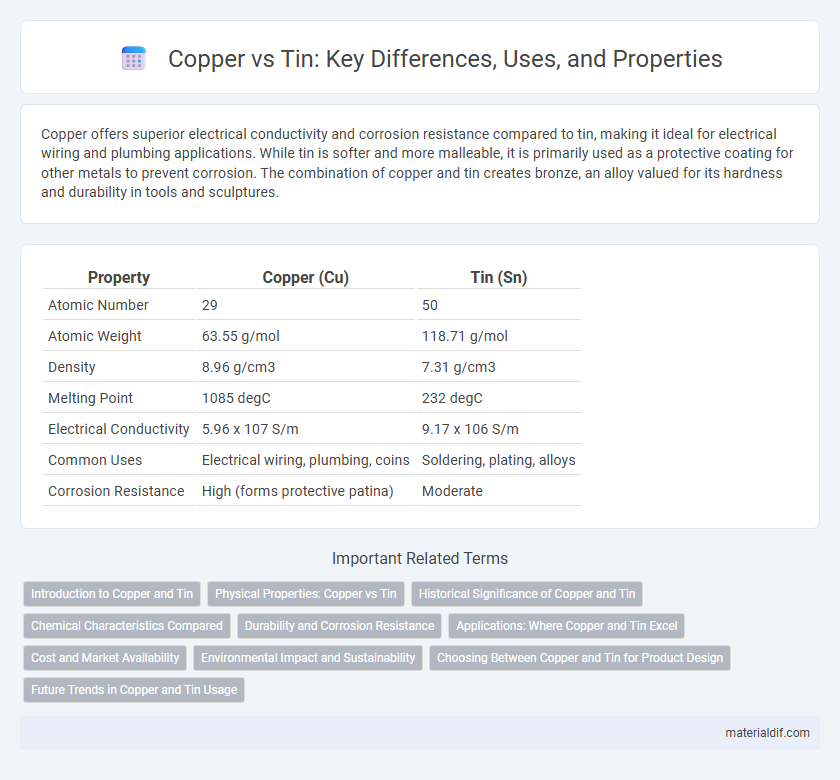

Table of Comparison

| Property | Copper (Cu) | Tin (Sn) |

|---|---|---|

| Atomic Number | 29 | 50 |

| Atomic Weight | 63.55 g/mol | 118.71 g/mol |

| Density | 8.96 g/cm3 | 7.31 g/cm3 |

| Melting Point | 1085 degC | 232 degC |

| Electrical Conductivity | 5.96 x 107 S/m | 9.17 x 106 S/m |

| Common Uses | Electrical wiring, plumbing, coins | Soldering, plating, alloys |

| Corrosion Resistance | High (forms protective patina) | Moderate |

Introduction to Copper and Tin

Copper is a highly conductive metal known for its excellent electrical and thermal properties, widely used in electrical wiring and plumbing. Tin, a malleable post-transition metal, is primarily valued for its corrosion resistance and is commonly utilized as a protective coating on other metals. While copper provides superior conductivity, tin enhances durability through its resistance to oxidation and corrosion.

Physical Properties: Copper vs Tin

Copper exhibits higher electrical and thermal conductivity compared to tin, making it superior for electrical wiring and heat exchange applications. While copper has a melting point of 1085degC, tin melts at a much lower temperature of 232degC, affecting their suitability in high-temperature environments. Copper's density of 8.96 g/cm3 contrasts with tin's lighter density of 7.31 g/cm3, influencing their use in weight-sensitive designs.

Historical Significance of Copper and Tin

Copper and tin were crucial in the formation of early human civilizations, with copper being one of the first metals to be widely used due to its natural occurrence and malleability. The combination of copper and tin resulted in bronze, an alloy that revolutionized tool-making and weaponry during the Bronze Age around 3300 BCE. This alloy's durability and utility marked a significant advancement over pure copper or tin, driving technological progress and societal development across ancient cultures.

Chemical Characteristics Compared

Copper exhibits excellent electrical conductivity and superior corrosion resistance due to its stable atomic structure, while tin is softer and more malleable with higher resistance to oxidation. Chemically, copper tends to form Cu^+ and Cu^{2+} ions, playing a vital role in redox reactions, whereas tin forms Sn^{2+} and Sn^{4+} ions and is often used as a protective coating against corrosion. Copper's ability to conduct heat and electricity efficiently contrasts with tin's primary use in alloying and soldering due to its lower melting point and chemical inertness.

Durability and Corrosion Resistance

Copper exhibits superior durability compared to tin, maintaining structural integrity under mechanical stress and high temperatures. Its corrosion resistance is enhanced by the formation of a protective patina, which prevents further oxidation, whereas tin tends to be more prone to rapid degradation in acidic or saline environments. This makes copper a preferred material in outdoor and industrial applications where longevity and resistance to environmental factors are critical.

Applications: Where Copper and Tin Excel

Copper excels in electrical wiring, plumbing, and industrial machinery due to its superior conductivity and corrosion resistance. Tin is primarily used in soldering, coating, and food packaging, where its non-toxic properties and oxidation resistance are critical. These distinctive applications underscore copper's dominance in electrical and structural uses versus tin's role in protective and joint-making materials.

Cost and Market Availability

Copper generally has a higher market price compared to tin due to its widespread industrial demand and limited supply. Tin, though less expensive, is more readily available in global markets, benefiting from abundant reserves and lower extraction costs. Cost efficiency in manufacturing often drives the choice between copper and tin depending on specific application and budget constraints.

Environmental Impact and Sustainability

Copper mining and processing generally have a higher environmental impact than tin due to greater energy consumption and more extensive habitat disruption, but copper is more widely recycled and has a well-established recycling infrastructure that enhances its sustainability. Tin, while less energy-intensive to extract, often comes from artisanal and small-scale mines with less regulated environmental practices, potentially leading to local ecological degradation and pollution. Both metals require improved supply chain transparency and sustainable mining practices to minimize their ecological footprints and support long-term resource availability.

Choosing Between Copper and Tin for Product Design

Copper offers superior electrical conductivity and corrosion resistance compared to tin, making it ideal for applications requiring durability and efficient current flow. Tin, while less conductive, provides excellent solderability and is often used as a protective coating to prevent copper oxidation in electronic components. Designers should weigh copper's performance benefits against tin's cost-effectiveness and protective properties when selecting materials for product design.

Future Trends in Copper and Tin Usage

Future trends indicate a rising demand for copper driven by its critical role in renewable energy technologies, electric vehicles, and advanced electronics, outpacing tin usage which remains primarily in solder and plating applications. Innovations in copper recycling and extraction methods aim to meet sustainability goals and reduce environmental impact, enhancing copper's market position. Tin usage may see modest growth due to emerging applications in battery anodes and lead-free solders but is unlikely to match copper's expanding industrial and technological scope.

Copper vs Tin Infographic

materialdif.com

materialdif.com