Pure copper offers excellent electrical conductivity and corrosion resistance, making it ideal for electrical wiring and plumbing applications. Alloyed copper, such as bronze or brass, combines copper with other metals to enhance strength, durability, and machinability for industrial uses. Choosing between pure and alloyed copper depends on specific performance requirements and environmental conditions.

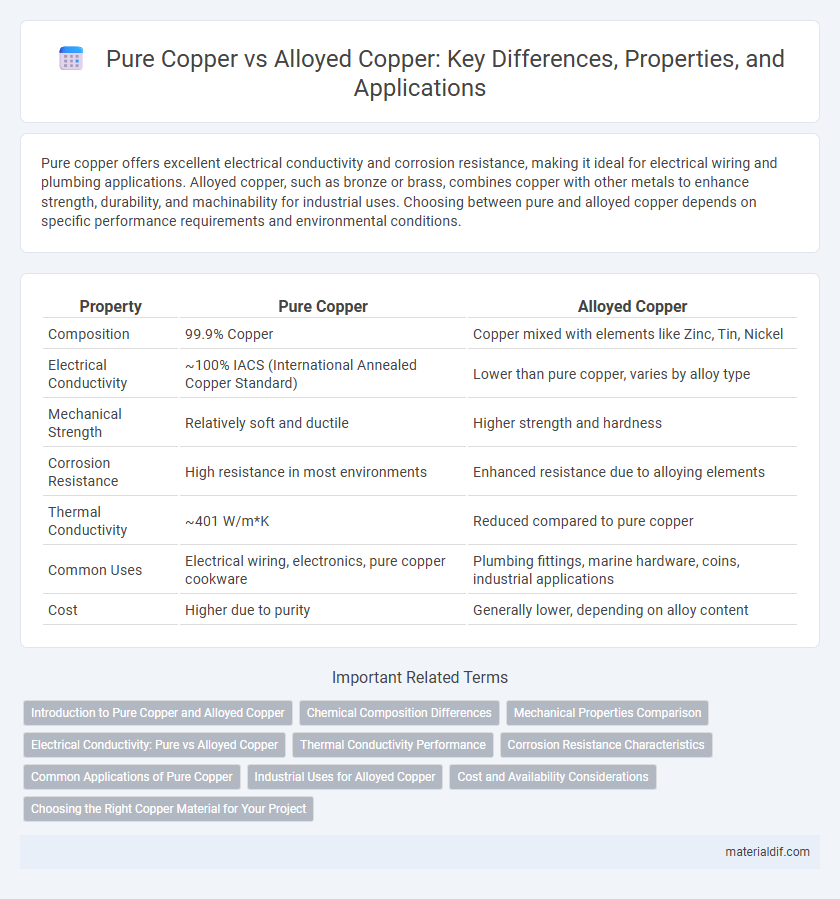

Table of Comparison

| Property | Pure Copper | Alloyed Copper |

|---|---|---|

| Composition | 99.9% Copper | Copper mixed with elements like Zinc, Tin, Nickel |

| Electrical Conductivity | ~100% IACS (International Annealed Copper Standard) | Lower than pure copper, varies by alloy type |

| Mechanical Strength | Relatively soft and ductile | Higher strength and hardness |

| Corrosion Resistance | High resistance in most environments | Enhanced resistance due to alloying elements |

| Thermal Conductivity | ~401 W/m*K | Reduced compared to pure copper |

| Common Uses | Electrical wiring, electronics, pure copper cookware | Plumbing fittings, marine hardware, coins, industrial applications |

| Cost | Higher due to purity | Generally lower, depending on alloy content |

Introduction to Pure Copper and Alloyed Copper

Pure copper, consisting of 99.9% copper content, is renowned for its exceptional electrical and thermal conductivity, malleability, and corrosion resistance, making it ideal for electrical wiring and plumbing applications. Alloyed copper, created by combining copper with elements such as zinc, tin, or nickel, enhances mechanical strength, hardness, and resistance to wear and corrosion, enabling its use in industrial machinery and marine environments. The choice between pure and alloyed copper depends on the specific requirements of conductivity, durability, and environmental conditions.

Chemical Composition Differences

Pure copper consists primarily of copper atoms with a chemical composition of approximately 99.9% copper, allowing excellent electrical and thermal conductivity due to its minimal impurities. Alloyed copper contains additional elements such as zinc, tin, nickel, or aluminum, which alter its chemical structure and enhance properties like strength, corrosion resistance, and machinability. The difference in chemical composition between pure and alloyed copper significantly impacts their applications, with pure copper favored for electrical uses and alloyed copper preferred in mechanical and industrial environments.

Mechanical Properties Comparison

Pure copper exhibits excellent electrical and thermal conductivity but has relatively low tensile strength and hardness, making it more ductile and easier to deform under stress. Alloyed copper, such as bronze or brass, incorporates elements like tin or zinc to significantly enhance mechanical properties, including increased tensile strength, hardness, and wear resistance. These improvements in alloyed copper make it more suitable for structural applications and environments requiring greater mechanical durability.

Electrical Conductivity: Pure vs Alloyed Copper

Pure copper exhibits superior electrical conductivity, typically around 59.6 million siemens per meter (MS/m), making it the preferred choice for electrical wiring and components. Alloyed copper, containing elements such as zinc or tin, experiences reduced conductivity due to scattering of electrons at atomic boundaries, with values often dropping below 50 MS/m depending on the alloy composition. This decreased conductivity in alloyed copper results in higher electrical resistance, which can impact efficiency in power transmission and electronic applications.

Thermal Conductivity Performance

Pure copper exhibits exceptional thermal conductivity, typically around 401 W/m*K, making it one of the most efficient materials for heat transfer applications. In contrast, alloyed copper, which contains elements such as zinc, tin, or nickel, demonstrates reduced thermal conductivity due to increased electron scattering caused by these impurities. This reduction in thermal performance is critical when selecting materials for applications requiring rapid and efficient heat dissipation, such as heat exchangers and electrical components.

Corrosion Resistance Characteristics

Pure copper exhibits excellent corrosion resistance due to its stable oxide layer that protects the metal from further oxidation in various environments. Alloyed copper, such as bronze or brass, often shows enhanced mechanical properties but may have altered corrosion resistance depending on the alloying elements, which can introduce galvanic corrosion or improve resistance in specific conditions. Understanding the specific application and environmental exposure is crucial for selecting between pure copper and copper alloys to optimize longevity and performance.

Common Applications of Pure Copper

Pure copper's excellent electrical conductivity makes it the preferred material for electrical wiring, electronics, and power generation equipment. Its superior thermal conductivity and corrosion resistance enable its use in heat exchangers, plumbing, and roofing applications. Pure copper is also widely used in coinage, musical instruments, and antimicrobial surfaces due to its natural durability and biostatic properties.

Industrial Uses for Alloyed Copper

Alloyed copper, such as bronze and brass, offers enhanced mechanical strength, corrosion resistance, and thermal conductivity, making it ideal for industrial applications like electrical connectors, plumbing fittings, and marine hardware. Pure copper's high electrical and thermal conductivity suits applications requiring efficient energy transfer but lacks the durability found in alloys. Industries rely on alloyed copper to balance performance and longevity in demanding environments.

Cost and Availability Considerations

Pure copper offers superior electrical conductivity and corrosion resistance but tends to be more expensive and less readily available than alloyed copper. Alloyed copper, incorporating elements like zinc or tin, reduces cost and improves mechanical strength, making it more accessible for mass production. Cost efficiency and availability of raw materials drive the choice between pure and alloyed copper for industrial applications.

Choosing the Right Copper Material for Your Project

Pure copper offers exceptional electrical and thermal conductivity, making it ideal for applications requiring maximum efficiency and corrosion resistance. Alloyed copper, enhanced with elements like zinc or tin, provides increased strength, hardness, and wear resistance, suitable for structural or mechanical components. Selecting the right copper material depends on balancing conductivity needs with mechanical properties and environmental conditions of the specific project.

Pure Copper vs Alloyed Copper Infographic

materialdif.com

materialdif.com