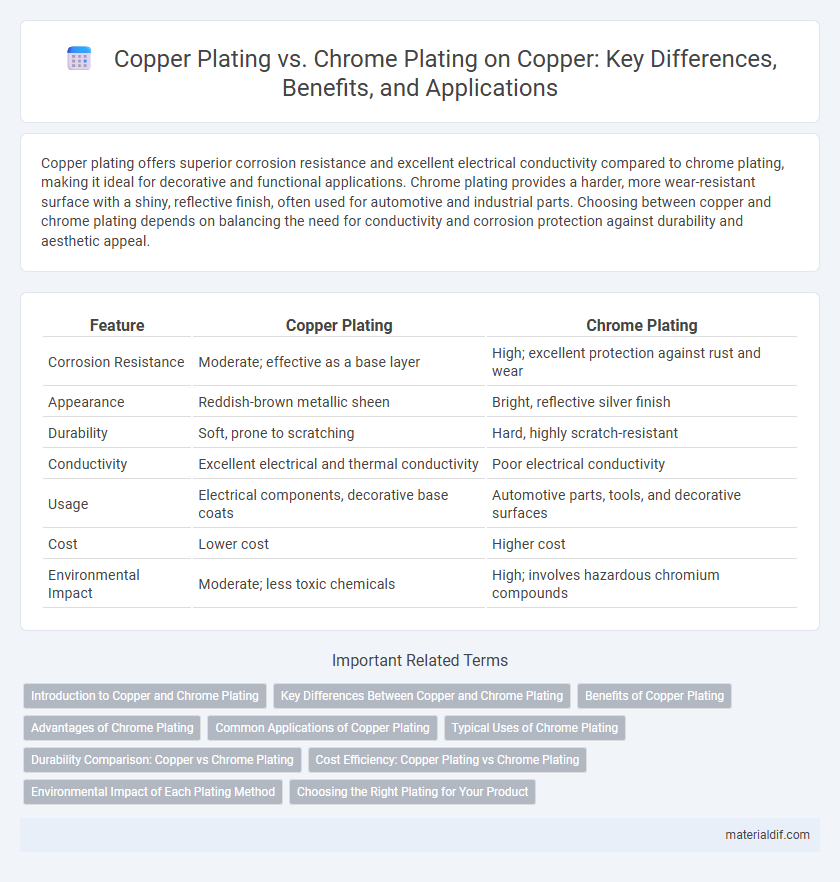

Copper plating offers superior corrosion resistance and excellent electrical conductivity compared to chrome plating, making it ideal for decorative and functional applications. Chrome plating provides a harder, more wear-resistant surface with a shiny, reflective finish, often used for automotive and industrial parts. Choosing between copper and chrome plating depends on balancing the need for conductivity and corrosion protection against durability and aesthetic appeal.

Table of Comparison

| Feature | Copper Plating | Chrome Plating |

|---|---|---|

| Corrosion Resistance | Moderate; effective as a base layer | High; excellent protection against rust and wear |

| Appearance | Reddish-brown metallic sheen | Bright, reflective silver finish |

| Durability | Soft, prone to scratching | Hard, highly scratch-resistant |

| Conductivity | Excellent electrical and thermal conductivity | Poor electrical conductivity |

| Usage | Electrical components, decorative base coats | Automotive parts, tools, and decorative surfaces |

| Cost | Lower cost | Higher cost |

| Environmental Impact | Moderate; less toxic chemicals | High; involves hazardous chromium compounds |

Introduction to Copper and Chrome Plating

Copper plating provides excellent electrical conductivity and corrosion resistance, making it ideal for electronic components and decorative finishes. Chrome plating offers superior hardness and a reflective, mirror-like surface, commonly used for automotive parts and household fixtures. Both methods enhance metal durability, but copper plating excels in electrical applications while chrome plating prioritizes aesthetic appeal and surface protection.

Key Differences Between Copper and Chrome Plating

Copper plating provides excellent electrical conductivity and superior corrosion resistance, making it ideal for electronic components and decorative applications. Chrome plating offers a hard, reflective surface with high wear resistance and chemical stability, commonly used for automotive parts and tools. Unlike chrome, copper plating is softer and more malleable, allowing better solderability but less surface hardness.

Benefits of Copper Plating

Copper plating offers superior corrosion resistance and excellent electrical conductivity compared to chrome plating, making it ideal for electronic components and circuitry. Its exceptional adhesion properties improve the durability of subsequent plating layers, enhancing overall surface protection. Moreover, copper plating provides a smooth, uniform finish that enhances aesthetic appeal and prepares the metal for further decorative or functional coatings.

Advantages of Chrome Plating

Chrome plating offers superior corrosion resistance and a highly reflective, attractive finish that enhances durability in automotive and industrial applications. It provides excellent hardness, reducing wear and extending the lifespan of components exposed to harsh environments. Compared to copper plating, chrome plating delivers enhanced protection against tarnishing and oxidation, making it ideal for long-term use.

Common Applications of Copper Plating

Copper plating is widely used in electronics for its excellent electrical conductivity and corrosion resistance, making it ideal for printed circuit boards and connectors. It is also common in automotive and plumbing industries due to its superior adhesion and antifouling properties, enhancing durability in harsh environments. Unlike chrome plating, copper plating serves as an effective base layer for further metallic coatings, improving overall surface performance.

Typical Uses of Chrome Plating

Chrome plating is widely used in automotive parts, such as bumpers and rims, due to its excellent corrosion resistance and reflective finish. It is also common in household fixtures and tools, providing a durable, scratch-resistant surface. Industrial machinery components benefit from chrome plating for enhanced wear resistance and ease of cleaning.

Durability Comparison: Copper vs Chrome Plating

Copper plating provides excellent corrosion resistance and electrical conductivity, making it ideal for electronics and decorative applications, but it is softer and more prone to wear compared to chrome plating. Chrome plating offers superior hardness and abrasion resistance, significantly enhancing the durability of surfaces exposed to friction and harsh environmental conditions. When comparing durability, chrome plating outperforms copper plating in terms of wear resistance and longevity, especially in heavy-duty or industrial applications.

Cost Efficiency: Copper Plating vs Chrome Plating

Copper plating generally offers greater cost efficiency compared to chrome plating due to lower material and processing expenses. The affordability of copper sulfate solutions and simpler plating techniques reduce overall production costs, making copper plating ideal for budget-conscious applications. Chrome plating involves higher costs from toxic hexavalent chromium chemicals and stricter environmental compliance, increasing operational expenditures.

Environmental Impact of Each Plating Method

Copper plating involves the use of copper sulfate and sulfuric acid solutions, which can generate hazardous waste requiring careful disposal to prevent soil and water contamination. Chrome plating typically utilizes hexavalent chromium, a highly toxic and carcinogenic substance, posing significant environmental and health risks if improperly managed. Waste treatment and strict regulatory compliance are critical for both methods to minimize toxic effluents and protect ecosystems.

Choosing the Right Plating for Your Product

Copper plating offers superior electrical conductivity and excellent corrosion resistance, making it ideal for electronic components and decorative finishes requiring a warm, reddish hue. Chrome plating provides a hard, durable surface with high wear resistance and bright, reflective aesthetics, suitable for automotive parts and household fixtures. Selecting the right plating depends on the product's functional requirements, environmental exposure, and desired appearance, with copper preferred for conductivity and chrome favored for hardness and shine.

Copper Plating vs Chrome Plating Infographic

materialdif.com

materialdif.com