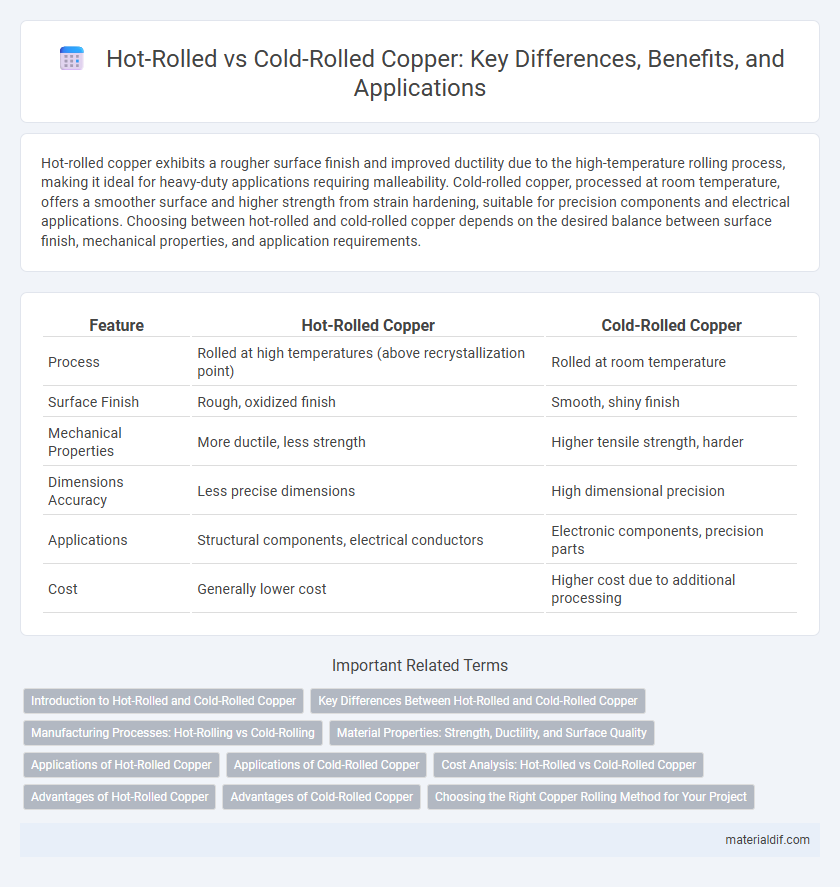

Hot-rolled copper exhibits a rougher surface finish and improved ductility due to the high-temperature rolling process, making it ideal for heavy-duty applications requiring malleability. Cold-rolled copper, processed at room temperature, offers a smoother surface and higher strength from strain hardening, suitable for precision components and electrical applications. Choosing between hot-rolled and cold-rolled copper depends on the desired balance between surface finish, mechanical properties, and application requirements.

Table of Comparison

| Feature | Hot-Rolled Copper | Cold-Rolled Copper |

|---|---|---|

| Process | Rolled at high temperatures (above recrystallization point) | Rolled at room temperature |

| Surface Finish | Rough, oxidized finish | Smooth, shiny finish |

| Mechanical Properties | More ductile, less strength | Higher tensile strength, harder |

| Dimensions Accuracy | Less precise dimensions | High dimensional precision |

| Applications | Structural components, electrical conductors | Electronic components, precision parts |

| Cost | Generally lower cost | Higher cost due to additional processing |

Introduction to Hot-Rolled and Cold-Rolled Copper

Hot-rolled copper undergoes processing at high temperatures, typically above 1,000degF, resulting in increased ductility and reduced internal stresses, making it suitable for structural applications requiring thicker gauges. Cold-rolled copper is processed at room temperature, enhancing surface finish, mechanical strength, and dimensional accuracy, which is ideal for precision components and electrical applications. Both methods influence the copper's microstructure and mechanical properties, tailoring it to specific industrial uses.

Key Differences Between Hot-Rolled and Cold-Rolled Copper

Hot-rolled copper is processed at high temperatures, resulting in a rougher surface and more malleable structure, while cold-rolled copper undergoes rolling at room temperature, producing smoother textures and enhanced strength. Hot-rolled copper is ideal for applications requiring flexibility and easier shaping, whereas cold-rolled copper is preferred for precision components demanding tighter tolerances and superior mechanical properties. Differences in microstructure, surface finish, and mechanical strength are critical factors determining the choice between hot-rolled and cold-rolled copper in industrial use.

Manufacturing Processes: Hot-Rolling vs Cold-Rolling

Hot-rolled copper undergoes deformation at temperatures above its recrystallization point, typically over 400degC, allowing for easier shaping and reduced internal stresses. Cold-rolled copper is processed below this temperature, often at room temperature, resulting in higher strength, improved surface finish, and enhanced dimensional accuracy due to strain hardening. The choice between hot-rolling and cold-rolling impacts copper's mechanical properties, grain structure, and potential applications in electrical and industrial components.

Material Properties: Strength, Ductility, and Surface Quality

Hot-rolled copper exhibits lower strength but higher ductility compared to cold-rolled copper due to its larger grain structure formed during processing at elevated temperatures. Cold-rolled copper demonstrates increased strength and improved surface quality with a smoother, more uniform finish resulting from deformation at room temperature. The enhanced surface integrity of cold-rolled copper makes it ideal for applications requiring precise dimensions and aesthetic appeal, whereas hot-rolled copper is better suited for components where flexibility is essential.

Applications of Hot-Rolled Copper

Hot-rolled copper is widely used in applications requiring enhanced mechanical strength and durability, such as electrical busbars, roofing, and cladding due to its improved grain structure and reduced internal stresses. Its excellent malleability and resistance to corrosion make it ideal for industrial components exposed to harsh environments, including heat exchangers and heat sinks. The hot-rolling process enables efficient production of large copper sheets and plates, facilitating versatile use in construction and electrical industries.

Applications of Cold-Rolled Copper

Cold-rolled copper offers precise dimensional tolerances and a smooth surface finish, making it ideal for electronic components, electrical connectors, and decorative applications. Its enhanced mechanical strength and improved conductivity support use in HVAC systems, roofing, and heat exchangers requiring durability and corrosion resistance. The uniform thickness and enhanced surface quality of cold-rolled copper also benefit circuits, capacitors, and automotive parts where reliable performance is critical.

Cost Analysis: Hot-Rolled vs Cold-Rolled Copper

Hot-rolled copper typically incurs lower production costs due to reduced processing time and lower energy consumption compared to cold-rolled copper. Cold-rolled copper, while more expensive, offers higher precision and improved mechanical properties, justifying its premium price for applications demanding tight tolerances. Cost analysis must also consider downstream benefits such as enhanced surface finish and dimensional accuracy in cold-rolled copper, which can reduce machining costs despite its initial higher price.

Advantages of Hot-Rolled Copper

Hot-rolled copper offers superior malleability and enhanced ductility, making it ideal for manufacturing robust electrical components and intricate architectural designs. Its coarse grain structure provides greater strength and improved resistance to wear and fatigue compared to cold-rolled copper. Furthermore, hot-rolled copper demonstrates better thermal conductivity, crucial for heat exchangers and electrical applications requiring efficient heat dissipation.

Advantages of Cold-Rolled Copper

Cold-rolled copper offers superior surface finish and dimensional accuracy compared to hot-rolled copper, making it ideal for applications requiring precise tolerances. Enhanced mechanical properties such as increased strength and hardness result from the strain hardening during cold rolling. Its improved conductivity and corrosion resistance ensure better performance in electrical and industrial uses.

Choosing the Right Copper Rolling Method for Your Project

Hot-rolled copper offers increased malleability and improved grain structure, making it ideal for large-scale projects requiring extensive shaping and durability. Cold-rolled copper provides superior surface finish and tighter dimensional tolerances, best suited for precision components and applications demanding high aesthetic quality. Selecting between hot-rolled and cold-rolled copper depends on project-specific factors such as mechanical requirements, surface finish expectations, and cost considerations.

Hot-Rolled Copper vs Cold-Rolled Copper Infographic

materialdif.com

materialdif.com