Enameled copper wire features a thin layer of insulating enamel coating that prevents short circuits and allows for tighter winding in electrical applications, making it ideal for motors, transformers, and inductors. Bare copper wire, lacking insulation, offers superior conductivity and flexibility but requires external insulation to avoid electrical hazards. Choosing between enameled and bare copper wire depends on the specific electrical or mechanical requirements, balancing insulation needs and conductivity efficiency.

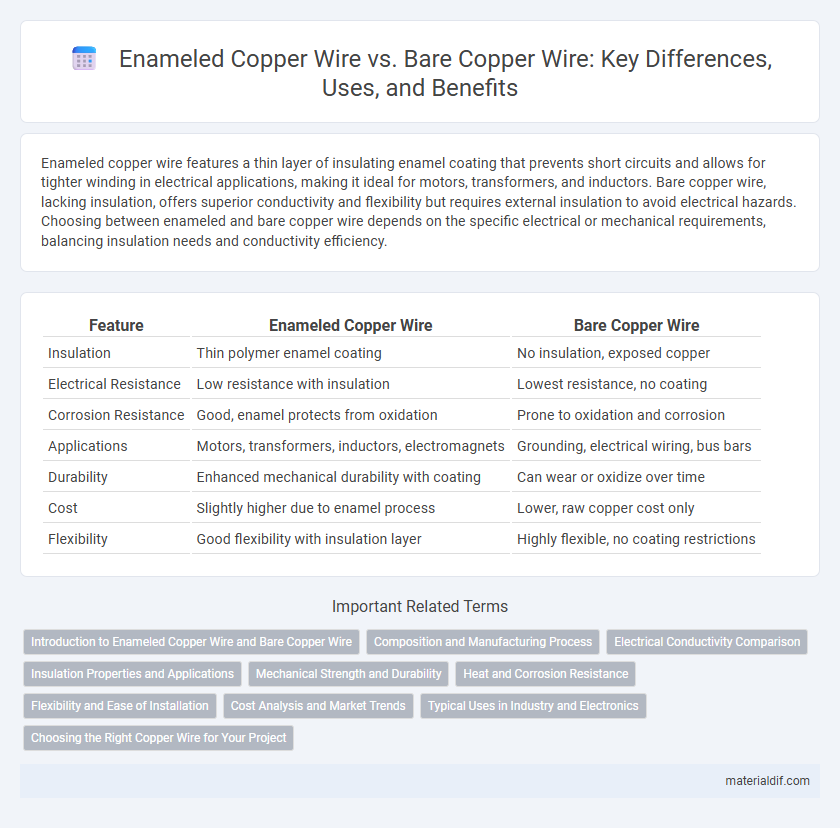

Table of Comparison

| Feature | Enameled Copper Wire | Bare Copper Wire |

|---|---|---|

| Insulation | Thin polymer enamel coating | No insulation, exposed copper |

| Electrical Resistance | Low resistance with insulation | Lowest resistance, no coating |

| Corrosion Resistance | Good, enamel protects from oxidation | Prone to oxidation and corrosion |

| Applications | Motors, transformers, inductors, electromagnets | Grounding, electrical wiring, bus bars |

| Durability | Enhanced mechanical durability with coating | Can wear or oxidize over time |

| Cost | Slightly higher due to enamel process | Lower, raw copper cost only |

| Flexibility | Good flexibility with insulation layer | Highly flexible, no coating restrictions |

Introduction to Enameled Copper Wire and Bare Copper Wire

Enameled copper wire consists of copper conductors coated with a thin layer of insulation, typically made from polymer or enamel varnish, providing electrical isolation while maintaining high conductivity. Bare copper wire, by contrast, is uncoated and offers excellent electrical conductivity but requires additional insulation to prevent short circuits and corrosion. The choice between enameled and bare copper wire depends on application requirements such as durability, insulation, and electrical performance.

Composition and Manufacturing Process

Enameled copper wire features a copper core coated with a thin layer of insulating enamel, achieved through a specialized coating and curing process that ensures uniform insulation for electrical applications. Bare copper wire consists solely of pure copper without any insulating layer, produced through casting, rolling, and drawing methods to attain the desired diameter and conductivity. The enamel insulation in enameled wire enhances electrical resistance and protects against short circuits, making it essential for winding coils in motors and transformers.

Electrical Conductivity Comparison

Enameled copper wire features a thin insulating layer that minimally impacts its electrical conductivity compared to bare copper wire, which offers maximum conductivity due to the absence of insulation. Bare copper wire typically exhibits conductivity around 59.6 MS/m (mega siemens per meter), while enameled copper wire maintains conductivity close to this value, with only slight reductions caused by the enamel coating. The choice between these wires depends on balancing conductivity needs with insulation requirements in electrical applications.

Insulation Properties and Applications

Enameled copper wire features a thin protective coating that provides excellent insulation properties, preventing short circuits and enhancing electrical performance in motors, transformers, and inductors. Bare copper wire lacks insulation, making it suitable for grounding, wiring in electrical panels, and applications where direct electrical contact is necessary. The choice between enameled and bare copper wire depends on the need for insulation and the specific requirements of electrical and electronic devices.

Mechanical Strength and Durability

Enameled copper wire features a thin insulating layer that enhances its durability by preventing corrosion and electrical short circuits, making it ideal for use in motors and transformers. In contrast, bare copper wire offers superior mechanical strength and flexibility but is more susceptible to environmental damage and oxidation. The enamel coating also provides abrasion resistance, extending the wire's operational lifespan under mechanical stress.

Heat and Corrosion Resistance

Enameled copper wire features a thin insulation layer that significantly enhances heat resistance, allowing it to operate efficiently in high-temperature environments up to 200degC. Its protective enamel coating also provides superior corrosion resistance compared to bare copper wire, preventing oxidation and prolonging lifespan in harsh conditions. Bare copper wire, while excellent for conductivity, is more susceptible to corrosion and heat damage without protective insulation.

Flexibility and Ease of Installation

Enameled copper wire offers superior flexibility compared to bare copper wire due to its thin insulating coating, allowing easier bending and manipulation during installation in tight spaces. This insulation also prevents short circuits without the need for extra protective layers, simplifying the wiring process. Bare copper wire, while highly conductive, is stiffer and requires additional insulation measures, making it less convenient for flexible or compact installations.

Cost Analysis and Market Trends

Enameled copper wire typically incurs higher production costs due to the insulation coating process, which adds value by enhancing durability and electrical performance compared to bare copper wire. Market trends indicate growing demand for enameled copper wire in industries like electric motors and transformers, driven by its superior heat resistance and efficiency. Bare copper wire remains cost-effective for general electrical applications, maintaining steady market presence due to its lower price point and ease of installation.

Typical Uses in Industry and Electronics

Enameled copper wire is predominantly used in electromagnetic applications such as transformers, inductors, and motors due to its insulated coating that prevents short circuits and enhances durability. Bare copper wire finds its primary use in grounding, electrical wiring, and bus bars, where direct conductivity and corrosion resistance are essential. In electronics, enameled wire supports compact coil winding for inductors and solenoids, while bare copper wire enables efficient current flow in circuit boards and connectors.

Choosing the Right Copper Wire for Your Project

Enameled copper wire, coated with a thin insulating layer, is ideal for electromagnetic applications such as transformers, inductors, and motors where electrical insulation is crucial. Bare copper wire, free of insulation, offers superior conductivity and is preferred for grounding, electrical wiring, and grounding applications where corrosion resistance and maximum current flow are priorities. Selecting the right copper wire depends on the project's electrical insulation requirements, environmental conditions, and current-carrying capacity to ensure efficiency and safety.

Enameled Copper Wire vs Bare Copper Wire Infographic

materialdif.com

materialdif.com