Copper foil offers superior flexibility and thinness, making it ideal for intricate electronic applications requiring precise shielding and conductivity. Copper tape, often backed with an adhesive, provides easy application for electromagnetic interference (EMI) shielding and grounding on larger surfaces. Both materials excel in durability and corrosion resistance, but the choice depends on the specific project's adherence and shaping needs.

Table of Comparison

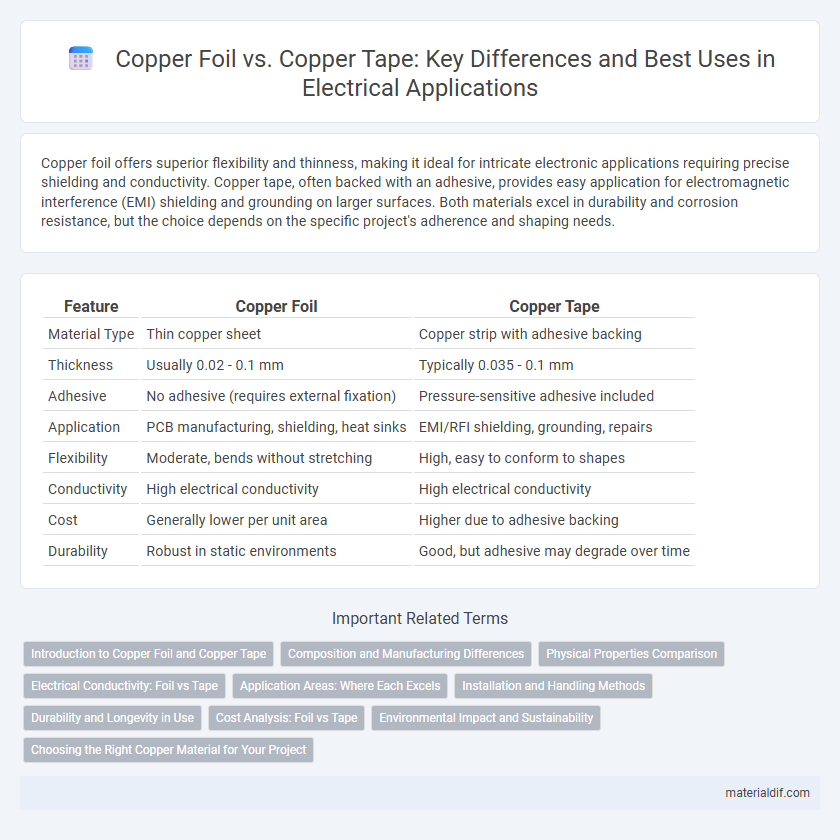

| Feature | Copper Foil | Copper Tape |

|---|---|---|

| Material Type | Thin copper sheet | Copper strip with adhesive backing |

| Thickness | Usually 0.02 - 0.1 mm | Typically 0.035 - 0.1 mm |

| Adhesive | No adhesive (requires external fixation) | Pressure-sensitive adhesive included |

| Application | PCB manufacturing, shielding, heat sinks | EMI/RFI shielding, grounding, repairs |

| Flexibility | Moderate, bends without stretching | High, easy to conform to shapes |

| Conductivity | High electrical conductivity | High electrical conductivity |

| Cost | Generally lower per unit area | Higher due to adhesive backing |

| Durability | Robust in static environments | Good, but adhesive may degrade over time |

Introduction to Copper Foil and Copper Tape

Copper foil is a thin, flexible sheet of copper metal widely used for electrical grounding, EMI shielding, and circuit board manufacturing due to its excellent conductivity and malleability. Copper tape consists of narrow strips of copper foil backed with adhesive, making it ideal for quick repairs, sealing, and conductivity in electronics and crafting applications. Both materials provide effective copper conductors but differ in form factor and ease of application.

Composition and Manufacturing Differences

Copper foil is typically produced through rolling or electro-deposition processes, resulting in thin, uniform sheets of pure copper with excellent conductivity and flexibility. Copper tape, on the other hand, consists of a copper foil base combined with an adhesive layer, often coated with acrylic or silicone, enabling easy application and strong adhesion to surfaces. The primary compositional difference lies in copper tape's dual-layer structure, integrating adhesive materials, whereas copper foil is solely metallic copper without adhesives.

Physical Properties Comparison

Copper foil exhibits superior flexibility and thinner gauge, typically ranging from 0.012 mm to 0.1 mm, making it ideal for precision applications and tight bends. Copper tape, generally thicker and reinforced with adhesive backing, offers enhanced durability and ease of application on irregular surfaces, with thicknesses commonly around 0.05 mm to 0.2 mm. Both materials provide excellent electrical conductivity and corrosion resistance, but their mechanical strength and adhesion properties vary significantly based on thickness and backing composition.

Electrical Conductivity: Foil vs Tape

Copper foil offers superior electrical conductivity due to its uniform thickness and pure composition, making it ideal for high-precision electronic applications. Copper tape, while conductive, often includes adhesive layers that can slightly reduce overall conductivity but provides flexibility for shielding and grounding purposes. Both materials serve distinct roles in electrical systems where conductivity and application method are critical.

Application Areas: Where Each Excels

Copper foil is widely used in electronics manufacturing, particularly for printed circuit boards (PCBs) due to its thinness and excellent conductivity. Copper tape excels in electromagnetic interference (EMI) shielding and grounding applications, providing flexibility and ease of application on irregular surfaces. Both materials serve critical roles in electrical insulation and repair, but copper foil dominates in precision electronic components while copper tape is preferred for quick fixes and shielding tasks.

Installation and Handling Methods

Copper foil offers a thin, flexible option that adheres easily to curved surfaces through conductive adhesives, making it ideal for precise electronic shielding applications. Copper tape, often backed with a pressure-sensitive adhesive, allows for quick application and repositioning, which benefits tasks requiring easy installation and maintenance. Handling copper foil demands careful cutting and placement to avoid creases, whereas copper tape's strip format simplifies alignment and layering during installation.

Durability and Longevity in Use

Copper foil offers higher durability and longer lifespan in electronic applications due to its uniform thickness and strong adhesion properties. Copper tape is generally less durable, prone to peeling and corrosion over time, making it suitable for temporary or less demanding uses. The choice between copper foil and copper tape depends on the required longevity and environmental conditions of the project.

Cost Analysis: Foil vs Tape

Copper foil offers a more cost-effective solution for large-scale industrial applications due to its lower price per square meter and higher durability, reducing replacement frequency and maintenance expenses. Copper tape, while initially more expensive per unit area, provides greater flexibility and ease of application for small-scale or precision tasks, potentially lowering labor costs and waste. Evaluating total cost of ownership, including material, installation, and longevity, is essential for determining the best option between copper foil and copper tape in electronics, EMI shielding, and crafting projects.

Environmental Impact and Sustainability

Copper foil and copper tape both offer high conductivity and corrosion resistance, but copper foil is generally more sustainable due to its thinner gauge, which requires less raw material and reduces environmental footprint during production. Copper tape often contains an adhesive layer that can introduce non-recyclable components, complicating disposal and recycling efforts. Choosing copper foil over copper tape can minimize waste and support circular economy goals by enhancing material recoverability and reducing the overall environmental impact.

Choosing the Right Copper Material for Your Project

Copper foil offers thin, flexible sheets ideal for precise electronic applications and shielding, while copper tape provides adhesive backing for easy installation on surfaces requiring conductivity or grounding. Selecting the right copper material depends on project needs such as thickness, ease of application, and electrical performance. For intricate circuit boards, copper foil ensures high conductivity and flexibility; for repairs or EMI shielding, copper tape delivers convenience and durability.

Copper Foil vs Copper Tape Infographic

materialdif.com

materialdif.com