Low alloy copper contains a small percentage of other metals, enhancing its mechanical strength while maintaining excellent electrical and thermal conductivity. High alloy copper, enriched with higher concentrations of elements like nickel or chromium, offers superior corrosion resistance and increased hardness for demanding industrial applications. Choosing between low alloy and high alloy copper depends on the balance required between conductivity, durability, and environmental resistance.

Table of Comparison

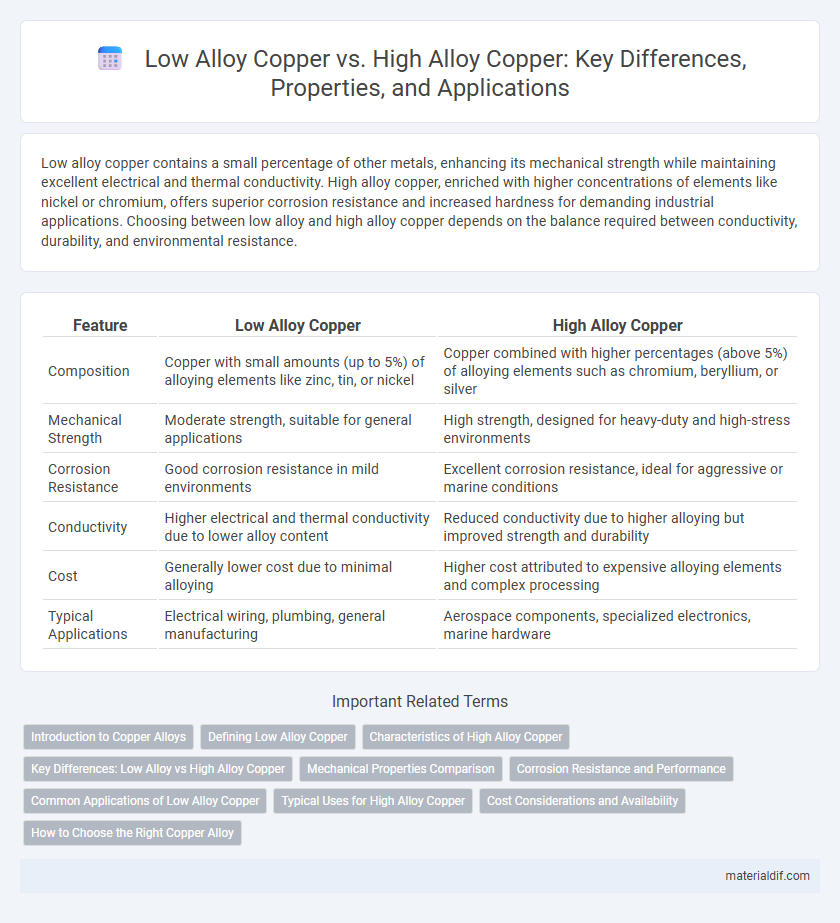

| Feature | Low Alloy Copper | High Alloy Copper |

|---|---|---|

| Composition | Copper with small amounts (up to 5%) of alloying elements like zinc, tin, or nickel | Copper combined with higher percentages (above 5%) of alloying elements such as chromium, beryllium, or silver |

| Mechanical Strength | Moderate strength, suitable for general applications | High strength, designed for heavy-duty and high-stress environments |

| Corrosion Resistance | Good corrosion resistance in mild environments | Excellent corrosion resistance, ideal for aggressive or marine conditions |

| Conductivity | Higher electrical and thermal conductivity due to lower alloy content | Reduced conductivity due to higher alloying but improved strength and durability |

| Cost | Generally lower cost due to minimal alloying | Higher cost attributed to expensive alloying elements and complex processing |

| Typical Applications | Electrical wiring, plumbing, general manufacturing | Aerospace components, specialized electronics, marine hardware |

Introduction to Copper Alloys

Copper alloys are categorized into low alloy copper, typically containing less than 10% alloying elements, and high alloy copper, which includes significantly higher concentrations of metals such as nickel, tin, or zinc. Low alloy copper offers excellent electrical conductivity and corrosion resistance, making it suitable for electrical wiring and plumbing applications. High alloy copper provides enhanced mechanical strength, wear resistance, and thermal stability, often used in aerospace, marine, and industrial machinery where durability is critical.

Defining Low Alloy Copper

Low alloy copper contains small amounts of alloying elements, typically less than 5%, to enhance properties such as strength, corrosion resistance, and machinability while maintaining excellent electrical and thermal conductivity. Common alloying elements in low alloy copper include tin, phosphorus, and zinc, which contribute to improved mechanical performance without significantly compromising conductivity. This class of copper is widely used in electrical connectors, plumbing, and industrial applications where a balance between conductivity and durability is essential.

Characteristics of High Alloy Copper

High alloy copper contains a higher percentage of alloying elements such as nickel, tin, or zinc, which significantly enhance its mechanical strength and corrosion resistance compared to low alloy copper. This increased alloy content results in improved hardness, wear resistance, and stability at elevated temperatures, making it suitable for demanding industrial applications. High alloy copper also exhibits superior electrical conductivity retention under harsh environmental conditions.

Key Differences: Low Alloy vs High Alloy Copper

Low alloy copper contains a smaller percentage of alloying elements, typically less than 5%, resulting in enhanced electrical conductivity and improved corrosion resistance compared to high alloy copper. High alloy copper, with a higher concentration of elements like nickel, chromium, or zinc, offers superior strength, hardness, and heat resistance, making it suitable for more demanding industrial applications. The choice between low alloy and high alloy copper depends on balancing electrical performance with mechanical properties based on specific use case requirements.

Mechanical Properties Comparison

Low alloy copper typically exhibits enhanced mechanical strength and improved hardness due to alloying elements like zinc and tin, making it suitable for heavy-duty applications. High alloy copper, containing higher concentrations of elements such as nickel and beryllium, demonstrates superior tensile strength, corrosion resistance, and wear resistance, ideal for aerospace and electronic components. The mechanical properties of high alloy copper generally surpass those of low alloy copper in terms of durability and resistance to deformation under stress.

Corrosion Resistance and Performance

Low alloy copper typically contains small amounts of alloying elements such as phosphorus or silver, enhancing its corrosion resistance and electrical conductivity while maintaining good thermal performance in industrial applications. High alloy copper, enriched with significant percentages of metals like nickel or chromium, offers superior corrosion resistance, especially in aggressive environments, and improved mechanical strength for demanding performance requirements. The choice between low and high alloy copper hinges on the specific corrosion environment and performance needs, with high alloy variants excelling in marine, chemical, and high-stress contexts.

Common Applications of Low Alloy Copper

Low alloy copper is predominantly used in electrical connectors, plumbing tubes, and automotive components due to its enhanced mechanical strength and corrosion resistance. Its applications leverage improved conductivity and durability, making it ideal for building wiring, heat exchangers, and industrial machinery parts. In contrast to high alloy copper, which finds use in more specialized environments, low alloy variants serve widespread roles in infrastructure and manufacturing sectors.

Typical Uses for High Alloy Copper

High alloy copper is commonly used in electrical connectors, aerospace components, and heat exchangers due to its enhanced strength and corrosion resistance. Its superior thermal conductivity makes it ideal for high-performance electrical wiring and electronic devices. These properties enable reliable performance in harsh environments where low alloy copper would typically fail.

Cost Considerations and Availability

Low alloy copper generally offers a more cost-effective option due to its lower content of expensive alloying elements like nickel and chrome, making it widely available for large-scale industrial applications. High alloy copper, containing greater percentages of costly metals such as silver or beryllium, commands a higher price and is often produced in smaller quantities, limiting its availability. Cost considerations heavily influence the choice between low and high alloy copper, with low alloy variants preferred for budget-conscious projects and high alloy types reserved for specialized, high-performance needs.

How to Choose the Right Copper Alloy

Choosing the right copper alloy depends on the specific application requirements such as corrosion resistance, mechanical strength, and conductivity. Low alloy copper offers excellent electrical conductivity and is ideal for electrical components, while high alloy copper provides enhanced strength and corrosion resistance suitable for marine or chemical environments. Assessing factors like thermal stability, machinability, and cost efficiency ensures optimal selection between low and high alloy copper grades.

Low Alloy Copper vs High Alloy Copper Infographic

materialdif.com

materialdif.com