Copper alloys offer enhanced strength, corrosion resistance, and durability compared to pure copper, making them ideal for industrial and construction applications. Pure copper provides superior electrical and thermal conductivity, which is essential for electrical wiring and heat exchangers. Choosing between copper alloy and pure copper depends on the specific performance requirements of conductivity versus mechanical strength.

Table of Comparison

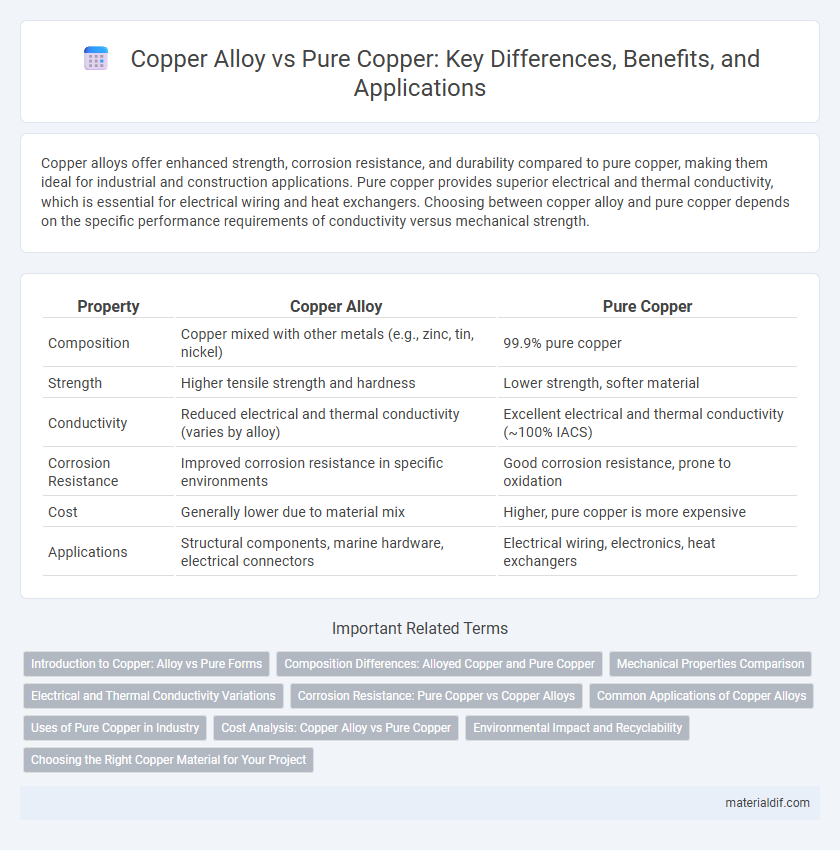

| Property | Copper Alloy | Pure Copper |

|---|---|---|

| Composition | Copper mixed with other metals (e.g., zinc, tin, nickel) | 99.9% pure copper |

| Strength | Higher tensile strength and hardness | Lower strength, softer material |

| Conductivity | Reduced electrical and thermal conductivity (varies by alloy) | Excellent electrical and thermal conductivity (~100% IACS) |

| Corrosion Resistance | Improved corrosion resistance in specific environments | Good corrosion resistance, prone to oxidation |

| Cost | Generally lower due to material mix | Higher, pure copper is more expensive |

| Applications | Structural components, marine hardware, electrical connectors | Electrical wiring, electronics, heat exchangers |

Introduction to Copper: Alloy vs Pure Forms

Copper alloys contain additional elements such as zinc, tin, or nickel, which enhance properties like strength, corrosion resistance, and machinability compared to pure copper. Pure copper is highly valued for its excellent electrical and thermal conductivity but lacks the mechanical durability found in alloys. Applications requiring a balance of conductivity and durability often choose copper alloys, while pure copper remains preferred in electrical wiring and heat exchangers.

Composition Differences: Alloyed Copper and Pure Copper

Copper alloys contain additional elements such as zinc, tin, or nickel, which alter their mechanical properties and corrosion resistance compared to pure copper. Pure copper consists of approximately 99.9% copper content, offering excellent electrical and thermal conductivity but limited strength and hardness. The precise composition of copper alloys varies depending on the specific alloy type, optimizing factors like toughness, machinability, and resistance to wear for industrial applications.

Mechanical Properties Comparison

Copper alloys exhibit enhanced mechanical properties compared to pure copper, including higher tensile strength and improved hardness, making them suitable for demanding structural applications. Pure copper offers superior electrical and thermal conductivity but lacks the mechanical robustness found in alloys such as brass or bronze. The alloying elements in copper alloys increase resistance to wear and fatigue, providing better durability under mechanical stress.

Electrical and Thermal Conductivity Variations

Copper alloys exhibit reduced electrical and thermal conductivity compared to pure copper due to the presence of alloying elements that disrupt electron and phonon flow. Pure copper, with its high purity level of 99.9% or greater, maintains exceptional conductivity--up to 59.6 MS/m for electrical conductivity and approximately 401 W/m*K for thermal conductivity. Variations in conductivity values among copper alloys depend on the specific alloy composition, often leading to trade-offs between enhanced mechanical properties and diminished conductive performance.

Corrosion Resistance: Pure Copper vs Copper Alloys

Copper alloys generally exhibit superior corrosion resistance compared to pure copper due to their enhanced ability to form stable oxide layers and resist environmental degradation. Brass and bronze, common copper alloys, contain elements like zinc and tin that improve resistance to tarnishing, pitting, and stress corrosion cracking. Pure copper is more prone to surface oxidation and corrosion in harsh environments, limiting its longevity in industrial applications.

Common Applications of Copper Alloys

Copper alloys, such as brass and bronze, are widely used in plumbing, electrical connectors, and marine hardware due to their enhanced strength and corrosion resistance compared to pure copper. These alloys offer improved machinability and wear resistance, making them ideal for industrial components like gears, valves, and bearings. In architectural applications, copper alloys provide durable and aesthetically pleasing finishes while maintaining excellent conductivity and antimicrobial properties.

Uses of Pure Copper in Industry

Pure copper is widely used in electrical wiring, electronics, and plumbing due to its excellent electrical conductivity, thermal conductivity, and corrosion resistance. It is essential in manufacturing components like transformers, motors, and circuit boards, where high purity ensures optimal performance and reliability. Pure copper's antimicrobial properties also make it suitable for medical equipment and surfaces in healthcare environments.

Cost Analysis: Copper Alloy vs Pure Copper

Copper alloys generally offer a cost-effective alternative to pure copper due to their enhanced mechanical properties and corrosion resistance, which reduce maintenance and replacement expenses. While pure copper has a higher upfront material cost, copper alloys provide better long-term value in applications requiring durability and strength. The cost difference varies by alloy composition, but copper alloys often balance performance and expense more efficiently than pure copper in industrial and electrical uses.

Environmental Impact and Recyclability

Copper alloys often contain metals like zinc, tin, or nickel, which can complicate recycling processes and increase environmental impact due to mixed metal recovery challenges. Pure copper is highly recyclable with minimal material loss, reducing energy consumption and lowering carbon emissions compared to extracting virgin copper ore. The environmental footprint of copper alloys tends to be higher since alloy components may require separate processing, whereas pure copper's recyclability efficiency supports sustainable material management.

Choosing the Right Copper Material for Your Project

Copper alloys offer enhanced strength, corrosion resistance, and machinability compared to pure copper, making them ideal for applications requiring durability and complex fabrication. Pure copper provides superior electrical and thermal conductivity, making it the preferred choice for electrical wiring and heat exchangers. Selecting between copper alloy and pure copper depends on the project's specific needs, balancing mechanical properties with conductivity requirements.

Copper Alloy vs Pure Copper Infographic

materialdif.com

materialdif.com