Red copper, known for its high purity, contains 99.9% copper and exhibits excellent electrical conductivity and corrosion resistance, making it ideal for electrical wiring and plumbing applications. Yellow copper, commonly referred to as brass, is an alloy of copper and zinc that offers greater strength and durability but reduced electrical conductivity compared to red copper. The choice between red and yellow copper depends on the required balance between conductivity, malleability, and mechanical strength for specific industrial or decorative uses.

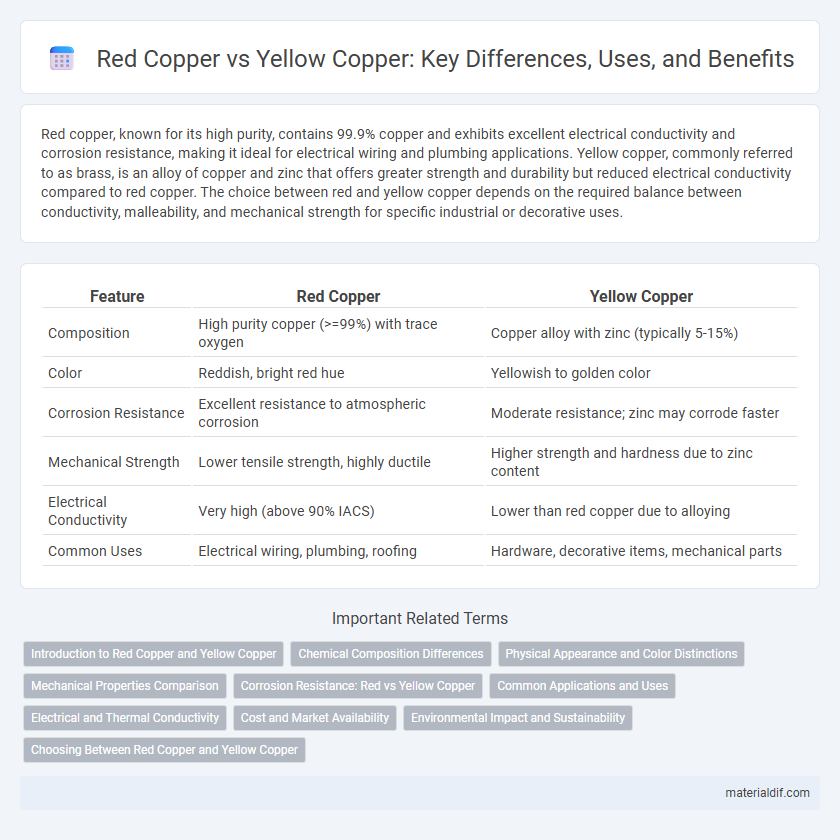

Table of Comparison

| Feature | Red Copper | Yellow Copper |

|---|---|---|

| Composition | High purity copper (>=99%) with trace oxygen | Copper alloy with zinc (typically 5-15%) |

| Color | Reddish, bright red hue | Yellowish to golden color |

| Corrosion Resistance | Excellent resistance to atmospheric corrosion | Moderate resistance; zinc may corrode faster |

| Mechanical Strength | Lower tensile strength, highly ductile | Higher strength and hardness due to zinc content |

| Electrical Conductivity | Very high (above 90% IACS) | Lower than red copper due to alloying |

| Common Uses | Electrical wiring, plumbing, roofing | Hardware, decorative items, mechanical parts |

Introduction to Red Copper and Yellow Copper

Red copper, primarily composed of 99.9% pure copper, is renowned for its excellent electrical conductivity and corrosion resistance, making it ideal for electrical wiring and plumbing applications. Yellow copper, also known as brass, is an alloy combining copper with zinc, offering enhanced strength and machinability, often used in decorative and mechanical components. Both materials highlight copper's versatility, with red copper excelling in pure conductivity and yellow copper valued for its durability and aesthetic appeal.

Chemical Composition Differences

Red copper primarily consists of 99.9% pure copper, characterized by its high conductivity and corrosion resistance due to minimal alloying elements. Yellow copper, often referred to as brass, contains significant amounts of zinc--typically between 5% and 40%--which alters its mechanical properties and corrosion behavior. The chemical composition difference directly influences their color, electrical conductivity, and suitability for various industrial applications.

Physical Appearance and Color Distinctions

Red copper exhibits a deep reddish hue due to its high purity and copper content, while yellow copper contains a higher proportion of zinc, giving it a brassy, yellowish appearance. The physical appearance of red copper is smooth with a metallic luster that enhances its rich red color, contrasting with yellow copper's lighter, more reflective surface. Color distinctions between red and yellow copper are essential for applications where aesthetic and material composition influence performance and appeal.

Mechanical Properties Comparison

Red copper exhibits superior tensile strength and ductility compared to yellow copper, making it ideal for applications requiring enhanced mechanical resilience. Yellow copper, while slightly lower in strength, offers increased machinability and corrosion resistance due to its higher zinc content. These differences in mechanical properties influence their selection for electrical wiring versus architectural uses, where durability and formability are critical.

Corrosion Resistance: Red vs Yellow Copper

Red copper, containing approximately 99.9% pure copper, exhibits superior corrosion resistance due to its minimal alloying elements, making it ideal for plumbing and electrical applications requiring durability. Yellow copper, an alloy primarily of copper and zinc (brass), has reduced corrosion resistance compared to red copper, especially in acidic or marine environments where zinc content accelerates oxidation processes. The higher purity and low zinc content in red copper enhance its resistance to tarnishing and pitting, ensuring longer-lasting performance in corrosive conditions.

Common Applications and Uses

Red copper, known for its high purity and excellent electrical conductivity, is commonly used in electrical wiring, plumbing, and roofing applications due to its corrosion resistance and malleability. Yellow copper, often an alloy such as brass, finds frequent use in decorative hardware, musical instruments, and valves because of its enhanced strength and aesthetic appeal. Both types serve crucial roles in construction and manufacturing, with red copper preferred for conductivity and yellow copper favored for durability and appearance.

Electrical and Thermal Conductivity

Red copper exhibits superior electrical and thermal conductivity compared to yellow copper due to its higher purity and minimal alloying elements, making it ideal for high-performance electrical wiring and heat transfer applications. Yellow copper, often alloyed with zinc to form brass, has lower electrical and thermal conductivity but offers greater mechanical strength and corrosion resistance. In precision electrical components and efficient heat exchangers, red copper's conductivity properties provide enhanced performance over the more durable yet less conductive yellow copper alloys.

Cost and Market Availability

Red copper typically costs more due to its higher purity and superior thermal conductivity, making it ideal for specialized electrical applications. Yellow copper, also known as brass, is more affordable and widely available in the market because it is an alloy composed of copper and zinc, which reduces its production cost. The broader availability of yellow copper supports its extensive use in plumbing and decorative items, whereas red copper's limited supply caters primarily to niche industrial demands.

Environmental Impact and Sustainability

Red copper typically contains a higher copper purity, which leads to better recyclability and lower environmental impact due to reduced mining requirements. Yellow copper, often alloyed with zinc (brass), may involve more complex recycling processes, potentially increasing energy consumption and waste. Sustainable copper use favors red copper for its enhanced recyclability and lower ecological footprint in circular economy practices.

Choosing Between Red Copper and Yellow Copper

Red copper, known for its high copper content of about 99.9%, offers superior electrical conductivity and corrosion resistance, making it ideal for electrical wiring and plumbing applications. Yellow copper, often an alloy such as brass, contains zinc and provides enhanced strength and machinability, suitable for decorative fixtures and mechanical components. When choosing between red and yellow copper, prioritize application requirements--opt for red copper for pure conductivity and corrosion resistance, whereas yellow copper is preferable for durability and aesthetic versatility.

Red Copper vs Yellow Copper Infographic

materialdif.com

materialdif.com