Copper electroforming involves the precise deposition of thick copper layers onto a mold to create highly detailed, freestanding metal parts with excellent structural integrity. Copper electroplating applies a thin layer of copper onto a substrate to enhance corrosion resistance, conductivity, and aesthetic appeal without significantly altering the object's dimensions. Both processes utilize electrochemical deposition, but electroforming is preferred for manufacturing complex components, while electroplating is ideal for surface finishing and protection.

Table of Comparison

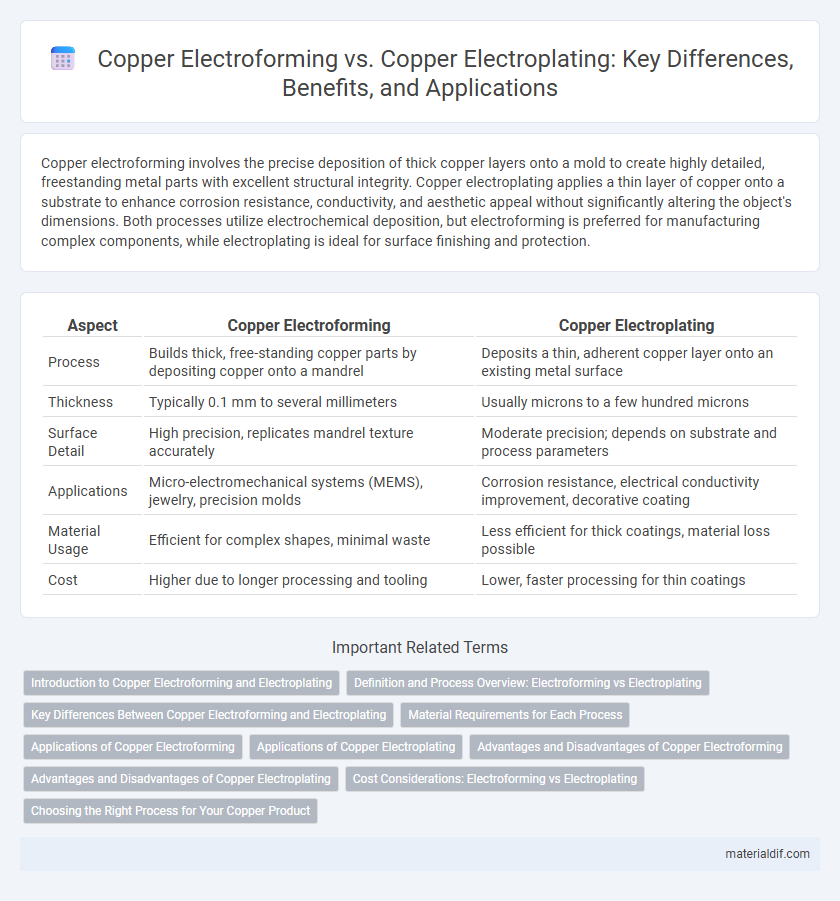

| Aspect | Copper Electroforming | Copper Electroplating |

|---|---|---|

| Process | Builds thick, free-standing copper parts by depositing copper onto a mandrel | Deposits a thin, adherent copper layer onto an existing metal surface |

| Thickness | Typically 0.1 mm to several millimeters | Usually microns to a few hundred microns |

| Surface Detail | High precision, replicates mandrel texture accurately | Moderate precision; depends on substrate and process parameters |

| Applications | Micro-electromechanical systems (MEMS), jewelry, precision molds | Corrosion resistance, electrical conductivity improvement, decorative coating |

| Material Usage | Efficient for complex shapes, minimal waste | Less efficient for thick coatings, material loss possible |

| Cost | Higher due to longer processing and tooling | Lower, faster processing for thin coatings |

Introduction to Copper Electroforming and Electroplating

Copper electroforming involves the deposition of thick, precise copper layers onto a mandrel to create detailed metal parts with high dimensional accuracy and excellent conductivity. Copper electroplating deposits a thinner copper coating on surfaces to enhance corrosion resistance, electrical conductivity, and aesthetic appeal. Both processes utilize electrochemical reactions but differ in thickness, purpose, and final application, with electroforming suited for complex component fabrication and electroplating primarily for surface finishing.

Definition and Process Overview: Electroforming vs Electroplating

Copper electroforming involves depositing thick layers of copper onto a mandrel to create self-supporting, precise metal parts, with the mandrel often removed after the process. Copper electroplating deposits a thin copper layer onto a conductive substrate primarily for surface enhancement, corrosion resistance, or conductivity improvement. Electroforming requires controlled current density and electrolyte composition to build up metal thickness, while electroplating focuses on achieving uniform coatings through regulated voltage and bath chemistry.

Key Differences Between Copper Electroforming and Electroplating

Copper electroforming involves depositing thick layers of pure copper onto a mandrel to create self-supporting metal parts, whereas copper electroplating deposits a thin, decorative or protective copper layer over a substrate. Electroforming requires precise control of current density and bath composition to achieve uniform thickness and fine feature replication, while electroplating focuses on adhesion and surface finish enhancement. The key differences lie in thickness, application purpose, and the method's ability to produce standalone structures versus surface coatings.

Material Requirements for Each Process

Copper electroforming requires a highly pure copper anode and a controlled electrolyte solution to deposit thick, precise, and durable copper layers, whereas copper electroplating utilizes a less stringent purity grade as it focuses on thin, decorative coatings. Electroforming demands substrate materials that can withstand extended immersion and maintain dimensional stability, often using conductive mandrels or molds. In contrast, electroplating substrates must be conductive and clean but do not require the same mechanical support due to the thinner copper layer applied.

Applications of Copper Electroforming

Copper electroforming is commonly used in applications demanding precise and complex shapes, such as in electronics for producing detailed connectors and micro components. It enables the creation of high-purity, seamless copper parts ideal for aerospace and medical devices requiring tight tolerances and exceptional conductivity. Unlike copper electroplating, which deposits a thin copper layer on surfaces, electroforming builds thicker, structurally robust components used in molds, RF shielding, and intricate art pieces.

Applications of Copper Electroplating

Copper electroplating is widely used in electronics manufacturing to create conductive surfaces on circuit boards and connectors, improving electrical conductivity and corrosion resistance. It is also essential in decorative applications, providing a shiny, durable finish on jewelry, automotive parts, and household fixtures. The technique enhances adhesion for subsequent plating layers and serves as an effective barrier against oxidation in various industrial components.

Advantages and Disadvantages of Copper Electroforming

Copper electroforming offers superior precision and thickness control compared to copper electroplating, making it ideal for complex, high-resolution components. Its main advantage lies in producing defect-free, seamless layers with excellent mechanical properties, though the process is slower and more expensive than electroplating. Disadvantages include higher costs, longer production times, and increased equipment complexity, which can limit its use to specialized applications requiring exceptional detail and durability.

Advantages and Disadvantages of Copper Electroplating

Copper electroplating offers advantages such as enhanced corrosion resistance, improved electrical conductivity, and cost-effective surface finishing for complex geometries. However, it has disadvantages including limited thickness control, potential for uneven deposition, and the need for rigorous waste management due to toxic chemical use. In contrast, copper electroforming enables thicker, more precise copper layers with better structural integrity but requires longer processing times and higher operational costs.

Cost Considerations: Electroforming vs Electroplating

Copper electroforming involves building up thick, precise copper layers, making it cost-effective for complex, high-precision parts despite higher initial setup expenses. Copper electroplating offers a thinner copper coating, reducing material costs and processing time, suitable for decorative and corrosion-resistant applications. Evaluating these methods depends on production volume, part complexity, and required copper thickness, impacting overall cost efficiency.

Choosing the Right Process for Your Copper Product

Copper electroforming creates thick, precise copper layers ideal for complex shapes and high durability applications, while copper electroplating deposits thinner layers primarily for decorative finishes and corrosion resistance. Selecting the right process depends on the product's functional requirements, with electroforming preferred for structural integrity and electroplating chosen for aesthetic enhancement. Consider factors such as thickness, detail resolution, and end-use environment to optimize performance and cost-effectiveness.

Copper Electroforming vs Copper Electroplating Infographic

materialdif.com

materialdif.com