Enameled copper wire features a thin insulating layer of enamel that prevents short circuits and enhances durability, making it ideal for winding coils in electrical motors and transformers. Magnet copper wire typically refers to magnet wire, which is a copper wire coated with a specific insulating varnish designed to withstand high temperatures in electromagnetic applications. The key difference lies in the type and thickness of the insulation, affecting thermal resistance and electrical performance in copper-based electrical components.

Table of Comparison

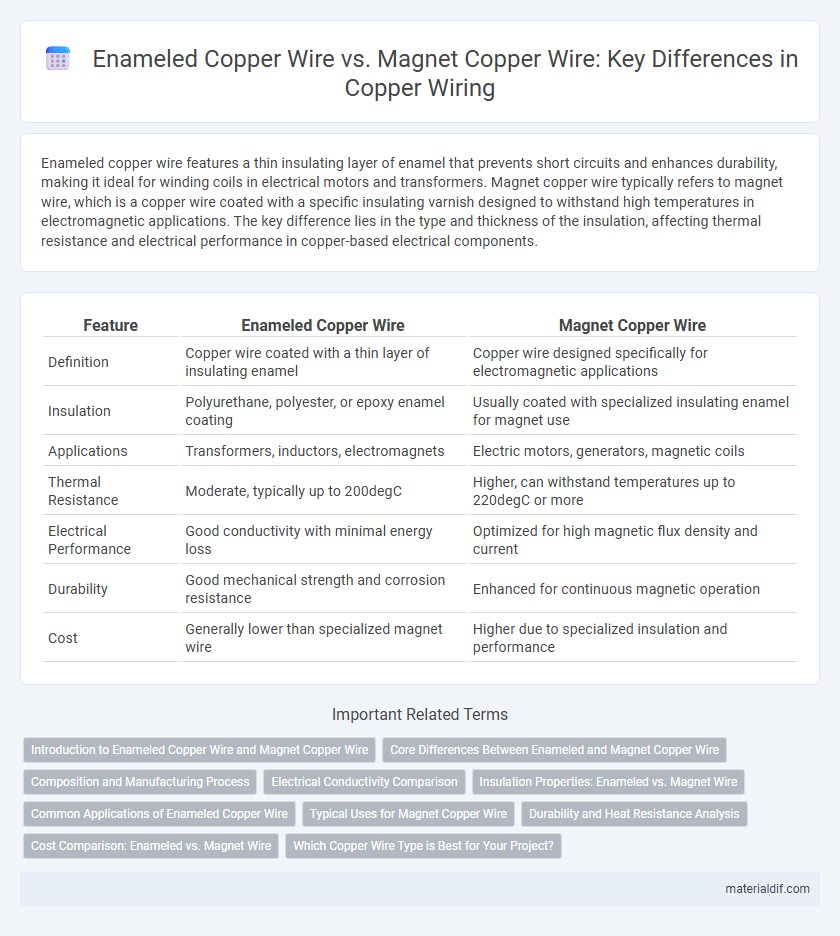

| Feature | Enameled Copper Wire | Magnet Copper Wire |

|---|---|---|

| Definition | Copper wire coated with a thin layer of insulating enamel | Copper wire designed specifically for electromagnetic applications |

| Insulation | Polyurethane, polyester, or epoxy enamel coating | Usually coated with specialized insulating enamel for magnet use |

| Applications | Transformers, inductors, electromagnets | Electric motors, generators, magnetic coils |

| Thermal Resistance | Moderate, typically up to 200degC | Higher, can withstand temperatures up to 220degC or more |

| Electrical Performance | Good conductivity with minimal energy loss | Optimized for high magnetic flux density and current |

| Durability | Good mechanical strength and corrosion resistance | Enhanced for continuous magnetic operation |

| Cost | Generally lower than specialized magnet wire | Higher due to specialized insulation and performance |

Introduction to Enameled Copper Wire and Magnet Copper Wire

Enameled copper wire, also known as magnet wire, is a copper conductor coated with a thin layer of insulation to prevent short circuits in electrical applications. This wire is essential in the manufacturing of transformers, inductors, motors, and electromagnets due to its excellent conductivity and insulation properties. Its enamel coating allows for tight winding without electrical contact between turns, making it ideal for electromagnetic device construction.

Core Differences Between Enameled and Magnet Copper Wire

Enameled copper wire features a thin layer of insulation made from enamel, enabling compact coil winding without short circuits, while magnet copper wire specifically refers to copper wire used in electromagnetic applications such as motors and transformers. The core difference lies in the insulation type and thermal resistance; enameled wire offers varying enamel coatings tailored for heat tolerance, whereas magnet wire must maintain consistent magnetic properties and durability under electromagnetic stress. These distinct characteristics influence their selection based on electrical insulation needs, thermal performance, and magnetic efficiency in industrial applications.

Composition and Manufacturing Process

Enameled copper wire features a thin insulating polymer coating applied through a precise enamel baking process, enhancing electrical insulation and heat resistance. Magnet copper wire, often synonymous with enameled wire, specifically refers to copper wire designed for electromagnetic coils, produced by tightly controlling the copper purity and enamel thickness to optimize magnetic performance. Both types utilize high-conductivity copper but differ in their enamel formulations and manufacturing steps to meet distinct electrical and thermal requirements.

Electrical Conductivity Comparison

Enameled copper wire features a thin insulating coating that slightly reduces its electrical conductivity compared to bare magnet copper wire, which remains uncoated to maximize current flow. Magnet copper wire is designed specifically for use in electrical motors and transformers, where high conductivity and minimal resistance are critical for efficient electromagnetic performance. The enamel coating on enameled wire allows for tight winding in coils without short circuits but results in marginally increased electrical resistance compared to bare magnet copper wire.

Insulation Properties: Enameled vs. Magnet Wire

Enameled copper wire features a thin, uniform insulation layer made of polymer enamel, providing excellent dielectric strength and resistance to heat, chemicals, and abrasion. Magnet copper wire, often used interchangeably with enameled wire, specifically refers to copper wire coated with insulating varnish optimized for electromagnetic applications, ensuring minimal interference and high magnetic permeability. Both types emphasize superior insulation properties, but magnet wire is typically tailored for enhanced magnetic efficiency in motors, transformers, and inductors.

Common Applications of Enameled Copper Wire

Enameled copper wire is commonly used in the manufacturing of transformers, inductors, and electric motors due to its excellent insulation properties and durability under high temperatures. It finds extensive application in communications equipment, automotive components, and household appliances, ensuring efficient electromagnetic functionality. The wire's thin insulation layer allows for tight coil winding, optimizing performance in compact electrical devices.

Typical Uses for Magnet Copper Wire

Magnet copper wire, primarily used in electromagnets, transformers, and inductors, offers excellent magnetic properties essential for efficient electromagnetic field generation and energy transfer. Its precise insulation and high conductivity make it ideal for applications requiring strong magnetic fields and minimal energy loss. Compared to enameled copper wire, magnet copper wire is optimized for performance in electric motors, solenoids, and magnetic coils in electronic devices.

Durability and Heat Resistance Analysis

Enameled copper wire features a thin insulating coating that enhances heat resistance and prevents short circuits, making it ideal for high-temperature environments. Magnet copper wire, often used in electromagnets and transformers, typically has superior durability due to its enamel insulation that withstands mechanical stress and thermal cycles. Comparing both, enameled copper wire offers better thermal protection, while magnet copper wire provides enhanced mechanical resilience and long-term durability under fluctuating heat conditions.

Cost Comparison: Enameled vs. Magnet Wire

Enameled copper wire generally costs less than magnet copper wire due to simpler insulation processes and lower material expenses. Magnet wire often features higher-quality enamel coatings that enhance durability and electrical performance, resulting in increased manufacturing costs. Choosing between the two depends on specific application requirements and budget constraints, with enameled wire offering a cost-effective solution for less demanding uses.

Which Copper Wire Type is Best for Your Project?

Enameled copper wire features a thin insulation coating ideal for producing compact electromagnetic coils with efficient heat resistance, making it perfect for motors, transformers, and inductors where space and thermal management are critical. Magnet copper wire, often synonymous with enameled wire, emphasizes magnetic properties and high conductivity essential for maximizing electromagnetic performance in projects requiring strong magnetic fields and minimal energy loss. Choosing the best copper wire depends on your project's specific electrical, thermal, and mechanical requirements, with enameled copper wire favored for precision winding and magnet copper wire preferred for applications prioritizing magnetic efficiency.

Enameled Copper Wire vs Magnet Copper Wire Infographic

materialdif.com

materialdif.com