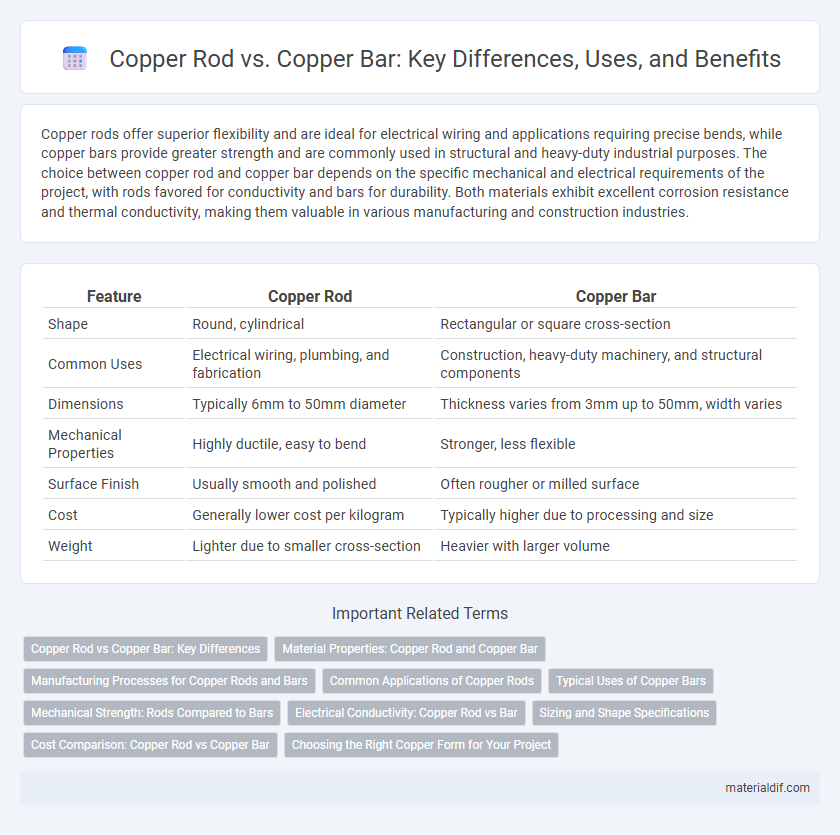

Copper rods offer superior flexibility and are ideal for electrical wiring and applications requiring precise bends, while copper bars provide greater strength and are commonly used in structural and heavy-duty industrial purposes. The choice between copper rod and copper bar depends on the specific mechanical and electrical requirements of the project, with rods favored for conductivity and bars for durability. Both materials exhibit excellent corrosion resistance and thermal conductivity, making them valuable in various manufacturing and construction industries.

Table of Comparison

| Feature | Copper Rod | Copper Bar |

|---|---|---|

| Shape | Round, cylindrical | Rectangular or square cross-section |

| Common Uses | Electrical wiring, plumbing, and fabrication | Construction, heavy-duty machinery, and structural components |

| Dimensions | Typically 6mm to 50mm diameter | Thickness varies from 3mm up to 50mm, width varies |

| Mechanical Properties | Highly ductile, easy to bend | Stronger, less flexible |

| Surface Finish | Usually smooth and polished | Often rougher or milled surface |

| Cost | Generally lower cost per kilogram | Typically higher due to processing and size |

| Weight | Lighter due to smaller cross-section | Heavier with larger volume |

Copper Rod vs Copper Bar: Key Differences

Copper rods are typically cylindrical and smaller in diameter, making them ideal for electrical wiring, fasteners, and manufacturing of springs due to their superior flexibility and conductivity. Copper bars have a rectangular or square cross-section, offering greater structural strength and are commonly used in construction, busbars, and heavy-duty industrial applications. The key differences lie in their shape, mechanical properties, and typical uses, with rods favored for precision and bars for strength.

Material Properties: Copper Rod and Copper Bar

Copper rods exhibit excellent electrical conductivity and are typically more malleable and flexible, making them ideal for electrical wiring and manufacturing processes requiring frequent bending. Copper bars, with their larger cross-sectional area, offer superior mechanical strength and rigidity, suitable for structural applications where durability and load-bearing capacity are critical. Both forms maintain high corrosion resistance and thermal conductivity, but their shapes influence specific material properties tailored to different industrial uses.

Manufacturing Processes for Copper Rods and Bars

Copper rods are typically manufactured using continuous casting followed by hot rolling, which ensures uniform grain structure and enhanced mechanical properties, making them ideal for electrical wiring and industrial applications. In contrast, copper bars are often produced through extrusion or hot rolling of billets, resulting in a rectangular or square cross-section suited for machining and structural uses. Both processes emphasize controlled cooling and precise dimensional tolerances to optimize conductivity and strength in copper components.

Common Applications of Copper Rods

Copper rods are extensively used in electrical wiring, manufacturing of electrical components, and plumbing due to their excellent conductivity and malleability. They are preferred in the production of screws, bolts, and fasteners given their ease of machining and corrosion resistance. Copper rods also find applications in the automotive industry for creating terminals, connectors, and heat exchangers.

Typical Uses of Copper Bars

Copper bars are commonly used in electrical applications such as busbars, grounding systems, and power distribution due to their excellent conductivity and mechanical strength. They also serve in manufacturing machinery components, automotive parts, and structural frameworks where durability and corrosion resistance are essential. These bars are preferred for heavy-duty industrial uses where shaping and machining into precise forms are required.

Mechanical Strength: Rods Compared to Bars

Copper rods exhibit higher mechanical strength compared to copper bars due to their refined grain structure achieved through continuous casting and drawing processes. This enhanced tensile strength and flexibility make copper rods ideal for electrical wiring and applications requiring durability under stress. In contrast, copper bars, with their larger cross-section and coarser grain, offer superior compressive strength but lower tensile performance.

Electrical Conductivity: Copper Rod vs Bar

Copper rods exhibit higher electrical conductivity compared to copper bars due to their typically purer composition and refined manufacturing processes. The cylindrical shape of copper rods allows for consistent current flow and reduced resistance, making them ideal for electrical wiring and conductive components. Copper bars, often used in structural applications, have slightly lower conductivity but offer enhanced mechanical strength and ease of machining.

Sizing and Shape Specifications

Copper rods generally have a smaller diameter range from 1 mm to 75 mm and feature a uniform cylindrical shape, making them ideal for applications requiring precise, consistent cross-sections. Copper bars, in contrast, come in larger sizes typically ranging from 10 mm to over 200 mm in width and thickness, with rectangular or square cross-sections designed for structural and heavy-duty electrical uses. The choice between copper rod and bar depends on the required mechanical strength, conductivity, and fabrication methods specific to each sizing and shape specification.

Cost Comparison: Copper Rod vs Copper Bar

Copper rods generally cost less per unit weight compared to copper bars due to differences in manufacturing processes and material density. Copper bars, being larger and denser, often incur higher raw material and processing expenses, impacting their overall price. Cost effectiveness depends on the specific application requirements, with copper rods favored for wiring and copper bars preferred in heavy-duty electrical components.

Choosing the Right Copper Form for Your Project

Choosing the right copper form depends on the specific requirements of your project, including shape, size, and mechanical properties. Copper rods, typically round and easy to shape, are ideal for applications requiring bending or intricate custom work, while copper bars offer a sturdier, rectangular profile suitable for structural or heavy-duty tasks. Understanding the differences in conductivity, tensile strength, and form factor ensures optimal performance and cost-efficiency in electrical, plumbing, or industrial applications.

Copper Rod vs Copper Bar Infographic

materialdif.com

materialdif.com