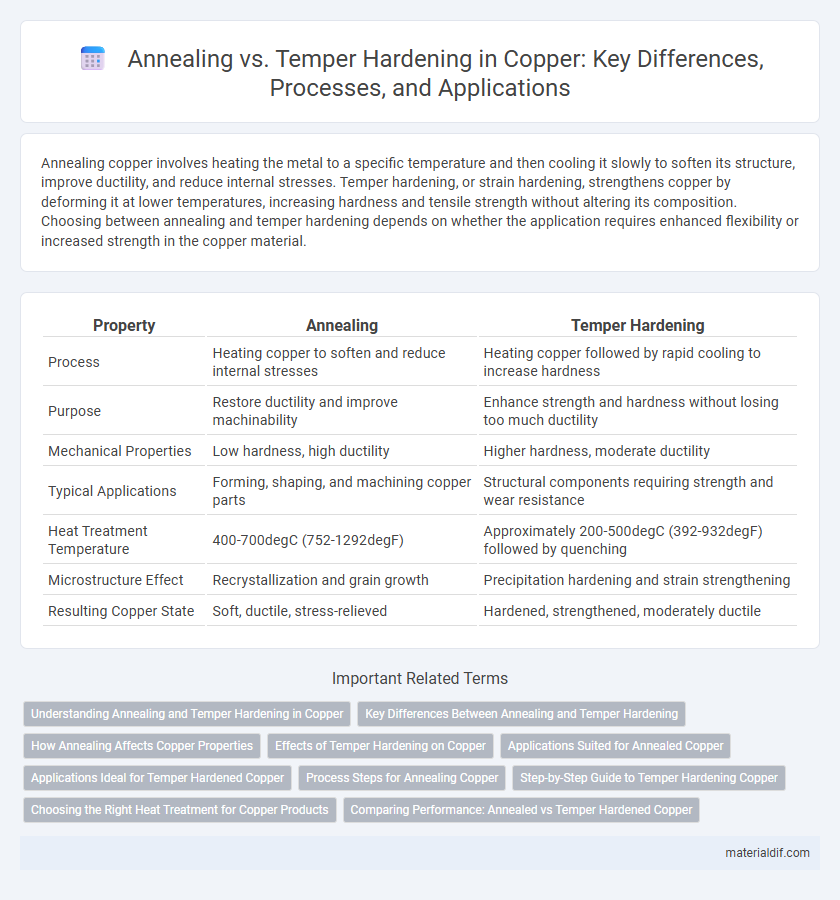

Annealing copper involves heating the metal to a specific temperature and then cooling it slowly to soften its structure, improve ductility, and reduce internal stresses. Temper hardening, or strain hardening, strengthens copper by deforming it at lower temperatures, increasing hardness and tensile strength without altering its composition. Choosing between annealing and temper hardening depends on whether the application requires enhanced flexibility or increased strength in the copper material.

Table of Comparison

| Property | Annealing | Temper Hardening |

|---|---|---|

| Process | Heating copper to soften and reduce internal stresses | Heating copper followed by rapid cooling to increase hardness |

| Purpose | Restore ductility and improve machinability | Enhance strength and hardness without losing too much ductility |

| Mechanical Properties | Low hardness, high ductility | Higher hardness, moderate ductility |

| Typical Applications | Forming, shaping, and machining copper parts | Structural components requiring strength and wear resistance |

| Heat Treatment Temperature | 400-700degC (752-1292degF) | Approximately 200-500degC (392-932degF) followed by quenching |

| Microstructure Effect | Recrystallization and grain growth | Precipitation hardening and strain strengthening |

| Resulting Copper State | Soft, ductile, stress-relieved | Hardened, strengthened, moderately ductile |

Understanding Annealing and Temper Hardening in Copper

Annealing copper involves heating it to a specific temperature and slowly cooling it to relieve internal stresses, enhance ductility, and improve electrical conductivity. Temper hardening, also known as strain hardening or work hardening, increases copper's strength and hardness by deforming it at room temperature without changing its crystal structure. Understanding these processes is crucial for optimizing copper's mechanical and physical properties for electrical wiring, plumbing, and industrial applications.

Key Differences Between Annealing and Temper Hardening

Annealing copper involves heating the metal to a specific temperature and then slowly cooling it to soften the material, enhance ductility, and relieve internal stresses. Temper hardening, on the other hand, increases copper's strength and hardness by controlled cooling after heat treatment, often involving quenching followed by aging processes. The key differences lie in annealing promoting softness and flexibility, while temper hardening aims to improve mechanical strength and resistance to deformation.

How Annealing Affects Copper Properties

Annealing copper involves heating the metal to a specific temperature and then slowly cooling it, which softens the material and improves ductility by relieving internal stresses. This heat treatment enhances electrical conductivity and makes copper more malleable, facilitating easier shaping and bending without cracking. In contrast, temper hardening increases strength and hardness but reduces ductility and electrical conductivity, making annealing essential for applications requiring flexibility and high electrical performance.

Effects of Temper Hardening on Copper

Temper hardening significantly increases copper's tensile strength and hardness by inducing strain hardening through controlled deformation and heat treatment processes. This process enhances the material's resistance to wear and fatigue while maintaining good electrical conductivity, making it ideal for electrical and mechanical applications. Unlike annealing, temper hardening does not restore ductility but improves copper's mechanical properties for demanding environments.

Applications Suited for Annealed Copper

Annealed copper is ideal for applications requiring high ductility and excellent electrical conductivity, such as electrical wiring, plumbing, and heat exchangers. Its soft and malleable nature allows for easy forming and bending without cracking, making it suitable for intricate shapes and components. Industries focused on electrical and thermal efficiency often prefer annealed copper for its superior performance in conductivity and corrosion resistance.

Applications Ideal for Temper Hardened Copper

Temper hardened copper is ideal for electrical connectors, switchgear components, and industrial machinery parts requiring high strength combined with excellent electrical conductivity. It offers enhanced mechanical properties and improved wear resistance compared to annealed copper, making it suitable for applications involving mechanical stress and frequent handling. This treatment provides a balance of hardness and ductility, essential for durable, high-performance components in electrical and mechanical systems.

Process Steps for Annealing Copper

Annealing copper involves heating the metal to a temperature typically between 400degC and 700degC, holding it at that temperature to allow recrystallization, and then cooling it slowly to relieve internal stresses and soften the material. This thermal process restores ductility and improves electrical conductivity by reducing dislocations in the crystal lattice. Annealing contrasts with temper hardening, which uses controlled cooling and quenching to increase hardness and strength rather than soften the copper.

Step-by-Step Guide to Temper Hardening Copper

Temper hardening copper involves a precise step-by-step process starting with solution annealing, where the copper is heated to approximately 800degC to dissolve alloying elements. The next critical step is rapid quenching, usually in water or brine, to retain a supersaturated solid solution. Final aging at temperatures between 150degC and 350degC for several hours precipitates strengthening phases, significantly enhancing copper's hardness and mechanical properties.

Choosing the Right Heat Treatment for Copper Products

Annealing copper involves heating the metal to a specific temperature and then cooling it slowly to soften the material, improve ductility, and relieve internal stresses for enhanced workability. Temper hardening, on the other hand, combines controlled heating and rapid cooling to increase copper's strength and hardness without significantly reducing its ductility, making it suitable for applications requiring durability and wear resistance. Selecting the appropriate heat treatment depends on the desired balance between mechanical properties and formability, with annealing favored for shaping processes and temper hardening chosen for finished parts requiring higher strength.

Comparing Performance: Annealed vs Temper Hardened Copper

Annealed copper exhibits superior electrical conductivity and increased ductility due to its soft, recrystallized grain structure, making it ideal for applications requiring extensive forming or bending. Temper hardened copper, in contrast, offers enhanced mechanical strength and higher hardness while maintaining reasonable conductivity, suitable for structural components under mechanical stress. The performance trade-off depends on whether flexibility or strength is prioritized in copper-based applications.

Annealing vs Temper Hardening Infographic

materialdif.com

materialdif.com