Marine bronze is specifically formulated with enhanced corrosion resistance to withstand harsh seawater environments, making it ideal for ship fittings, propellers, and underwater applications. Architectural bronze, while also durable, emphasizes aesthetic appeal with a smoother finish and patina development suited for decorative elements like doors, railings, and sculptures. The primary distinction lies in marine bronze's superior strength and resistance to saltwater corrosion, whereas architectural bronze balances durability with ornamental qualities.

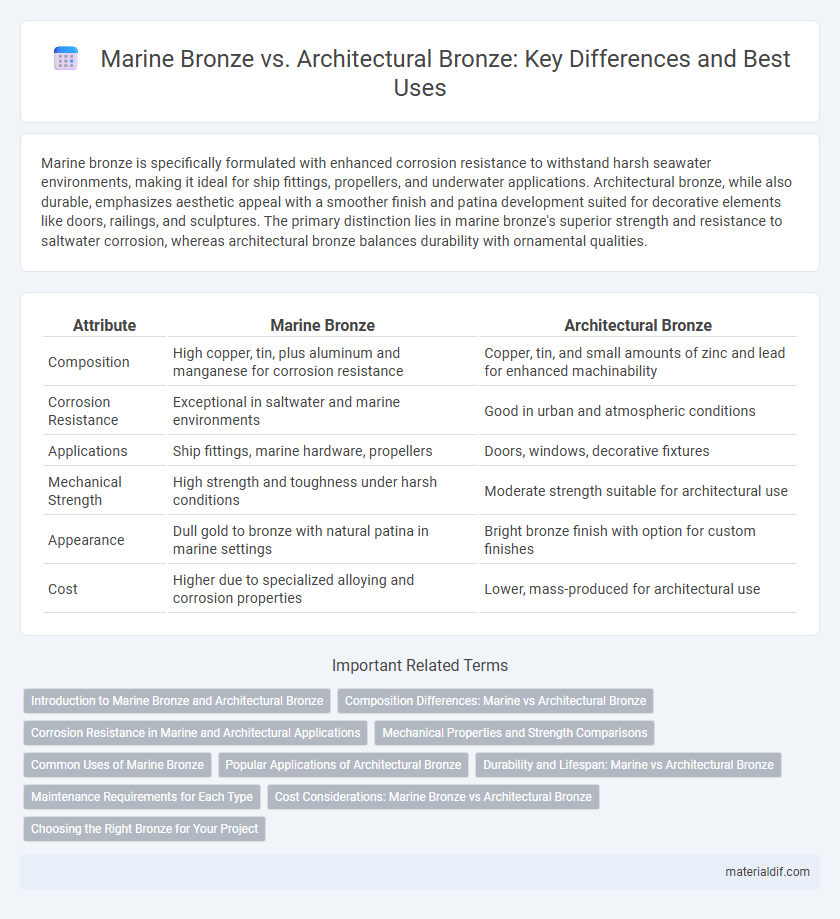

Table of Comparison

| Attribute | Marine Bronze | Architectural Bronze |

|---|---|---|

| Composition | High copper, tin, plus aluminum and manganese for corrosion resistance | Copper, tin, and small amounts of zinc and lead for enhanced machinability |

| Corrosion Resistance | Exceptional in saltwater and marine environments | Good in urban and atmospheric conditions |

| Applications | Ship fittings, marine hardware, propellers | Doors, windows, decorative fixtures |

| Mechanical Strength | High strength and toughness under harsh conditions | Moderate strength suitable for architectural use |

| Appearance | Dull gold to bronze with natural patina in marine settings | Bright bronze finish with option for custom finishes |

| Cost | Higher due to specialized alloying and corrosion properties | Lower, mass-produced for architectural use |

Introduction to Marine Bronze and Architectural Bronze

Marine bronze is a corrosion-resistant alloy specifically formulated to withstand harsh seawater environments, featuring high levels of copper, tin, and additives like aluminum or nickel to enhance durability and resistance to saltwater corrosion. Architectural bronze, composed primarily of copper and zinc with small amounts of lead and tin, is designed for aesthetic appeal and structural integrity in building applications, offering excellent corrosion resistance while maintaining a warm, attractive patina. Both marine and architectural bronze alloys provide unique benefits tailored to their environments, with marine bronze excelling in underwater durability and architectural bronze prioritized for visual appeal and weather resistance in construction.

Composition Differences: Marine vs Architectural Bronze

Marine bronze typically contains higher levels of copper, tin, and small amounts of nickel and iron, enhancing its corrosion resistance against seawater. Architectural bronze often includes more aluminum and manganese, providing improved strength and durability for structural applications. The compositional differences influence the respective alloys' performance in marine environments versus building exteriors.

Corrosion Resistance in Marine and Architectural Applications

Marine bronze, specifically designed for harsh saline environments, offers superior corrosion resistance due to its high copper and tin content combined with added elements like aluminum and nickel, which enhance its durability against saltwater corrosion. Architectural bronze, while containing similar base metals, prioritizes aesthetics and general outdoor durability but does not provide the same level of resistance to aggressive marine environments, making it more susceptible to pitting and surface degradation over time. The metallurgical composition of marine bronze ensures long-term structural integrity in marine applications, whereas architectural bronze is optimized for weather resistance and decorative use in urban and building environments.

Mechanical Properties and Strength Comparisons

Marine bronze alloys typically exhibit higher tensile strength and superior corrosion resistance compared to architectural bronze, making them ideal for harsh marine environments. Architectural bronze offers moderate mechanical properties with enhanced aesthetic qualities, suitable for structural and decorative applications where durability is essential but exposure to saltwater is limited. The higher copper, tin, and nickel content in marine bronze contributes to its increased hardness, yield strength, and resistance to dezincification, outperforming architectural bronze in mechanical performance under marine conditions.

Common Uses of Marine Bronze

Marine bronze is primarily used in shipbuilding and offshore structures due to its excellent corrosion resistance in saltwater environments. It is commonly found in propellers, pumps, valves, and submerged fasteners, ensuring durability and longevity in harsh marine conditions. Unlike architectural bronze, which is favored for decorative and structural applications in buildings, marine bronze is specifically engineered to withstand the challenges of marine exposure.

Popular Applications of Architectural Bronze

Architectural bronze is widely used for decorative and functional elements in building design, such as door frames, window sills, handrails, and elevator interiors due to its durability and aesthetic appeal. Unlike marine bronze, which is specifically formulated to resist corrosion in seawater environments, architectural bronze prioritizes appearance and malleability, making it ideal for intricate detailing and ornamental fixtures. Its popularity in commercial and residential architecture stems from its ability to retain a polished finish and resist tarnishing over time.

Durability and Lifespan: Marine vs Architectural Bronze

Marine bronze exhibits superior corrosion resistance due to its high copper and tin content combined with nickel and iron, making it ideal for harsh saltwater environments where durability is critical. Architectural bronze, while still corrosion-resistant, often includes aluminum for enhanced strength and aesthetic appeal, resulting in a slightly shorter lifespan when exposed to marine conditions. The lifespan of marine bronze structures typically exceeds 50 years with minimal maintenance, whereas architectural bronze components may require protective coatings and more frequent upkeep to achieve similar longevity in marine environments.

Maintenance Requirements for Each Type

Marine bronze exhibits superior corrosion resistance due to its high copper and tin content, requiring minimal maintenance in saltwater environments, whereas architectural bronze demands regular cleaning and protective coatings to prevent tarnishing and surface degradation. The presence of alloying elements like aluminum and nickel in architectural bronze improves its durability but still necessitates routine upkeep to maintain its aesthetic appeal in urban or industrial settings. Maintenance schedules for both types emphasize periodic inspection, with marine bronze benefiting from less frequent intervention compared to architectural bronze's need for consistent preservation efforts.

Cost Considerations: Marine Bronze vs Architectural Bronze

Marine bronze, composed primarily of copper, tin, and additional elements like nickel and iron, offers superior corrosion resistance in seawater but typically incurs higher material and processing costs compared to architectural bronze. Architectural bronze, an alloy partly consisting of copper and zinc, is more cost-effective for interior and exterior building applications where marine-grade corrosion resistance is unnecessary. Budget considerations for projects exposed to harsh marine environments often justify the premium price of marine bronze due to its extended durability and reduced maintenance expenses over time.

Choosing the Right Bronze for Your Project

Marine bronze, known for its high resistance to saltwater corrosion, is ideal for maritime applications such as boat fittings and underwater components, featuring a high copper and tin content with added elements like nickel and iron to enhance durability. Architectural bronze emphasizes aesthetic appeal and weather resistance, often used in decorative elements, doors, and facades, incorporating alloys that provide a warm patina and corrosion resistance suitable for urban environments. Selecting the right bronze depends on the project's specific environmental exposure, mechanical demands, and visual requirements, ensuring long-lasting performance and desired appearance.

Marine Bronze vs Architectural Bronze Infographic

materialdif.com

materialdif.com