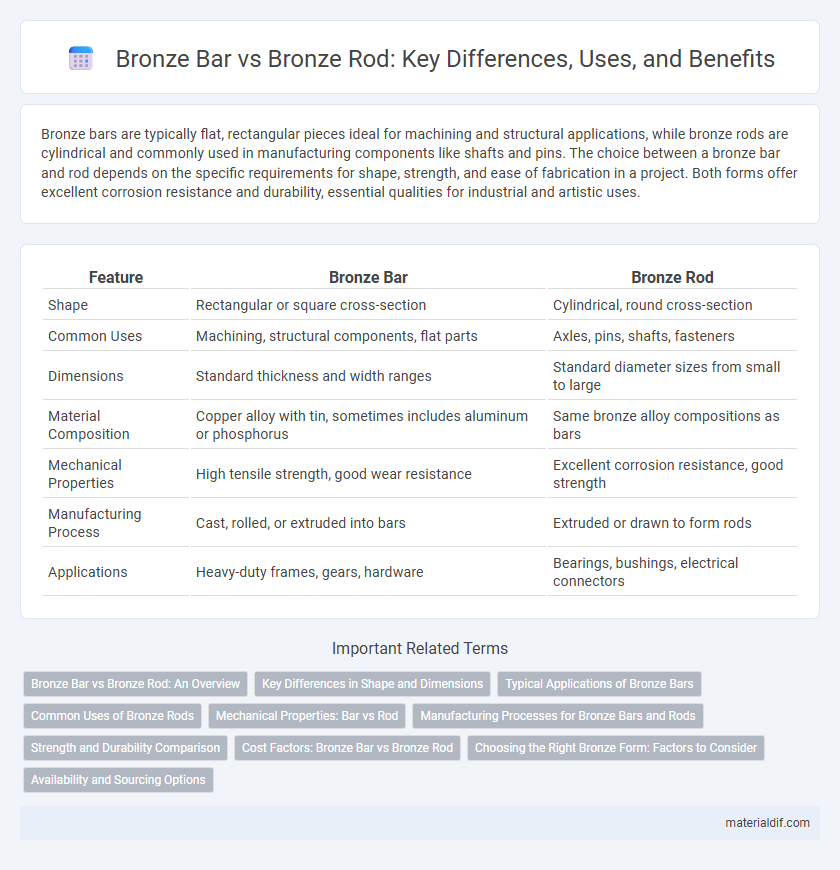

Bronze bars are typically flat, rectangular pieces ideal for machining and structural applications, while bronze rods are cylindrical and commonly used in manufacturing components like shafts and pins. The choice between a bronze bar and rod depends on the specific requirements for shape, strength, and ease of fabrication in a project. Both forms offer excellent corrosion resistance and durability, essential qualities for industrial and artistic uses.

Table of Comparison

| Feature | Bronze Bar | Bronze Rod |

|---|---|---|

| Shape | Rectangular or square cross-section | Cylindrical, round cross-section |

| Common Uses | Machining, structural components, flat parts | Axles, pins, shafts, fasteners |

| Dimensions | Standard thickness and width ranges | Standard diameter sizes from small to large |

| Material Composition | Copper alloy with tin, sometimes includes aluminum or phosphorus | Same bronze alloy compositions as bars |

| Mechanical Properties | High tensile strength, good wear resistance | Excellent corrosion resistance, good strength |

| Manufacturing Process | Cast, rolled, or extruded into bars | Extruded or drawn to form rods |

| Applications | Heavy-duty frames, gears, hardware | Bearings, bushings, electrical connectors |

Bronze Bar vs Bronze Rod: An Overview

Bronze bars and bronze rods differ primarily in shape and typical applications, with bars usually having flat, rectangular cross-sections and rods featuring circular cross-sections. Bronze bars are commonly used in machining, structural components, and decorative purposes, while bronze rods are preferred for cylindrical machining, fasteners, and shafts. Selecting between a bronze bar and a bronze rod depends on the specific mechanical requirements, ease of manufacturing, and the intended industrial application.

Key Differences in Shape and Dimensions

Bronze bars typically have a rectangular cross-section with flat surfaces, making them ideal for machining and fabrication where uniform thickness is required. Bronze rods feature a circular cross-section, which provides superior strength and is preferred for applications involving rotational forces or precise diameters. The choice between bronze bar and rod depends on the specific dimensional requirements and mechanical properties needed for the intended use.

Typical Applications of Bronze Bars

Bronze bars are commonly used in manufacturing bearings, bushings, and gears due to their excellent wear resistance and low friction properties. These bars also find typical applications in marine hardware, electrical components, and decorative architectural elements where corrosion resistance is crucial. Compared to bronze rods, bars offer more uniform cross-sectional stability, making them ideal for precision machining in heavy-duty industrial parts.

Common Uses of Bronze Rods

Bronze rods are commonly used in industrial applications such as machinery components, marine hardware, and electrical connectors due to their excellent corrosion resistance and high strength. They are preferred over bronze bars in precision machining and fabrication, where uniformity and exact dimensions are critical. Bronze rods also find extensive use in manufacturing bearings, bushings, and valves, benefiting from the alloy's superior wear resistance and thermal conductivity.

Mechanical Properties: Bar vs Rod

Bronze bars typically exhibit higher tensile strength and enhanced wear resistance compared to bronze rods due to their manufacturing process and cross-sectional uniformity. The denser microstructure of bronze bars provides superior fatigue resistance, making them ideal for heavy-load mechanical applications. In contrast, bronze rods offer greater flexibility and are better suited for intricate machining and components requiring precise dimensional tolerances.

Manufacturing Processes for Bronze Bars and Rods

Bronze bars are typically produced through continuous casting or extrusion, which allows for uniform cross-sections and consistent mechanical properties. Bronze rods often undergo hot rolling or drawing processes, enhancing their strength and surface finish to meet specific industrial standards. Both manufacturing methods emphasize precise control of temperature and cooling rates to optimize the bronze alloy's microstructure and performance.

Strength and Durability Comparison

Bronze bars typically offer greater strength and durability compared to bronze rods due to their larger cross-sectional area and uniform composition, which enhances resistance to wear and deformation. The solid, flat structure of bronze bars distributes stress more evenly, making them ideal for heavy-duty applications requiring high load-bearing capacity. In contrast, bronze rods, while still strong, may experience more surface wear over time and are better suited for precise, lighter-duty components where flexibility and ease of machining are priorities.

Cost Factors: Bronze Bar vs Bronze Rod

Bronze bars typically have lower manufacturing costs due to simpler production processes compared to bronze rods, which often require additional machining and finishing. The shape and size of bronze rods can lead to higher material waste and increased handling expenses, influencing the overall price. Cost factors for both products also depend on alloy composition, quantity ordered, and supplier pricing models.

Choosing the Right Bronze Form: Factors to Consider

Selecting between a bronze bar and a bronze rod depends primarily on the specific application, load requirements, and machining processes involved. Bronze bars often come in rectangular or square shapes, providing greater surface area for complex machining or structural use, while bronze rods are typically cylindrical, ideal for rotational parts like shafts or pins. Consider mechanical strength, dimensional tolerances, and ease of fabrication when deciding the suitable bronze form for industrial or manufacturing needs.

Availability and Sourcing Options

Bronze bars and bronze rods differ significantly in availability and sourcing options, with bronze bars typically offered in larger sizes and weights for heavy-duty industrial applications, while bronze rods are commonly available in smaller diameters suited for precision machining. Suppliers often stock bronze bars in standard alloys such as C932 and C954, ensuring wide accessibility for casting and fabrication, whereas bronze rods are frequently sourced in specialty grades like phosphor bronze to meet specific mechanical property requirements. Sourcing bronze bars can be more cost-effective for bulk orders, whereas bronze rods offer flexibility and faster delivery for smaller, custom projects.

Bronze Bar vs Bronze Rod Infographic

materialdif.com

materialdif.com