Gunmetal bronze, an alloy composed primarily of copper, tin, and zinc, is valued for its high hardness and excellent wear resistance, making it ideal for machine parts and bearings. Bell bronze, containing a higher tin content than gunmetal bronze, offers superior acoustic properties and durability, which is why it is traditionally used in the manufacturing of bells and musical instruments. Both alloys exhibit corrosion resistance but differ significantly in mechanical strength and sound quality, influencing their specific industrial and artistic applications.

Table of Comparison

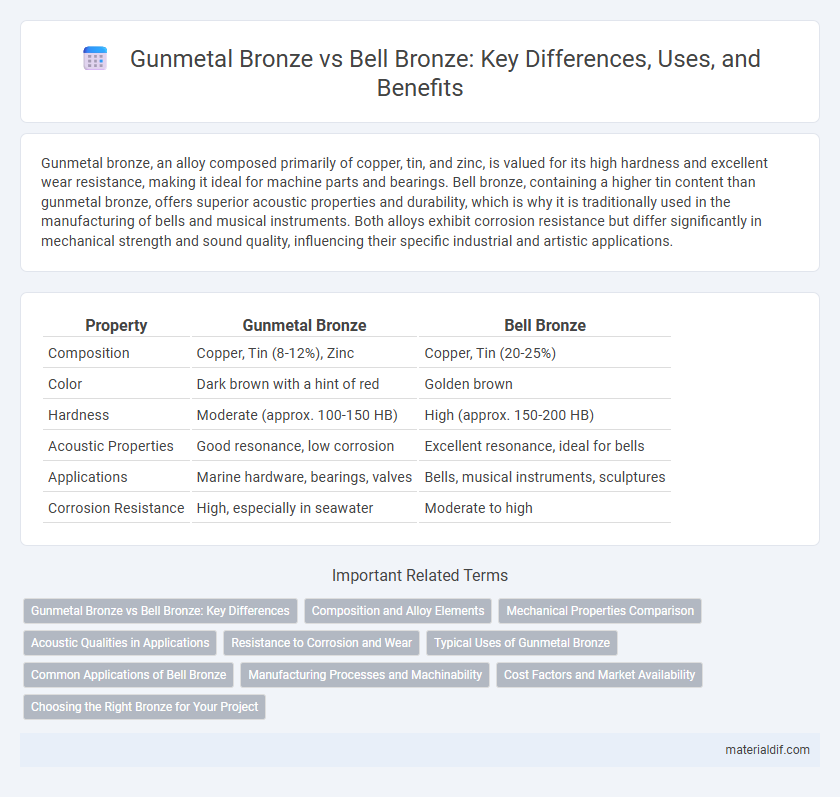

| Property | Gunmetal Bronze | Bell Bronze |

|---|---|---|

| Composition | Copper, Tin (8-12%), Zinc | Copper, Tin (20-25%) |

| Color | Dark brown with a hint of red | Golden brown |

| Hardness | Moderate (approx. 100-150 HB) | High (approx. 150-200 HB) |

| Acoustic Properties | Good resonance, low corrosion | Excellent resonance, ideal for bells |

| Applications | Marine hardware, bearings, valves | Bells, musical instruments, sculptures |

| Corrosion Resistance | High, especially in seawater | Moderate to high |

Gunmetal Bronze vs Bell Bronze: Key Differences

Gunmetal bronze is an alloy primarily composed of copper, tin, and zinc, known for its strength and corrosion resistance, often used in marine and industrial applications. Bell bronze, consisting mainly of copper and tin with a higher tin content, produces superior acoustic properties ideal for making bells and musical instruments. The key differences lie in their composition ratios and resulting properties: gunmetal bronze offers enhanced durability and machinability, while bell bronze is prized for its resonant sound quality.

Composition and Alloy Elements

Gunmetal bronze typically consists of approximately 88% copper, 10% tin, and 2% zinc, which enhances its corrosion resistance and machinability. Bell bronze contains a higher tin content, usually around 20-25%, with the remainder being mostly copper, providing superior hardness and acoustic properties essential for sound clarity. The distinct alloy compositions directly influence their mechanical performance, with gunmetal bronze favored for durability in industrial applications and bell bronze optimized for resonance in musical instruments.

Mechanical Properties Comparison

Gunmetal bronze exhibits higher tensile strength and superior corrosion resistance compared to bell bronze, making it ideal for applications requiring durability under harsh conditions. Bell bronze, characterized by its excellent hardness and elastic properties, provides exceptional resonance and wear resistance, which is crucial for musical instruments and precision bearings. The density and microstructure differences contribute to gunmetal bronze's toughness, whereas bell bronze's well-defined grain structure enhances its strength-to-weight ratio.

Acoustic Qualities in Applications

Gunmetal bronze offers a dense, durable composition ideal for use in applications requiring clear, bright acoustic qualities, such as wind instruments and bells with a sharp timbre. Bell bronze, typically a high-tin bronze alloy, excels in producing rich, resonant tones with sustained vibration, making it preferred for large bells and chimes. The distinct acoustic profiles stem from their metal density and alloy composition, directly influencing sound clarity, pitch stability, and tonal warmth in various musical and architectural contexts.

Resistance to Corrosion and Wear

Gunmetal bronze, an alloy primarily composed of copper, tin, and zinc, displays superior resistance to corrosion, especially in marine environments, due to its enhanced copper content and alloying elements that prevent oxidation. Bell bronze, typically made with a higher tin content, offers excellent wear resistance and tonal quality but is more susceptible to corrosion in harsh conditions compared to gunmetal bronze. The distinct compositions influence their performance; gunmetal bronze is preferred for mechanical applications requiring durability against corrosion, while bell bronze excels in acoustical uses requiring minimal wear and preservation of sound.

Typical Uses of Gunmetal Bronze

Gunmetal bronze is commonly used in applications requiring corrosion resistance and strength, such as marine hardware, valve components, and bushings. Its composition, typically a mixture of copper, tin, and zinc, provides excellent machinability and durability under harsh conditions. Gunmetal bronze is preferred in environments exposed to seawater or industrial chemicals where reliable performance and wear resistance are critical.

Common Applications of Bell Bronze

Bell bronze, also known as bell metal, is primarily used in the manufacturing of musical instruments such as bells, gongs, and cymbals due to its excellent resonance and durability. Its unique composition of approximately 78% copper and 22% tin provides superior acoustic properties, making it ideal for applications requiring clear, sustained sound. Unlike gunmetal bronze, which is favored for mechanical parts and industrial applications, bell bronze remains the preferred choice in artisanal and musical contexts.

Manufacturing Processes and Machinability

Gunmetal bronze, typically composed of copper, tin, and zinc, undergoes casting or sand casting methods that allow for precise shaping and good machinability due to its fine grain structure and moderate hardness. Bell bronze, a high-tin bronze alloy predominantly made of copper and tin, is traditionally cast in sand molds followed by extended aging to enhance its tensile strength and resonance but exhibits lower machinability because of its brittleness and hardness. Manufacturing bell bronze demands meticulous temperature control to avoid defects, while gunmetal bronze offers more versatility in machining and finishing processes, making it preferable for components requiring both durability and workability.

Cost Factors and Market Availability

Gunmetal bronze generally costs more than bell bronze due to its higher copper and tin content, which enhances durability and corrosion resistance. Bell bronze typically has a lower price point, attributed to a simpler alloy composition primarily consisting of copper and tin, making it more readily available in mass markets. Market availability favors bell bronze, especially in industries requiring lightweight and easily cast materials, while gunmetal bronze is preferred for high-strength applications despite its relatively limited supply.

Choosing the Right Bronze for Your Project

Gunmetal bronze, an alloy composed primarily of copper, tin, and zinc, offers excellent machinability and corrosion resistance, making it ideal for precision components and marine applications. Bell bronze, with a higher tin content typically around 20-25%, provides superior tonal quality and durability, favored in bell casting and musical instruments. Selecting between gunmetal bronze and bell bronze depends on the project's requirements for mechanical strength, acoustic properties, and environmental exposure.

Gunmetal Bronze vs Bell Bronze Infographic

materialdif.com

materialdif.com