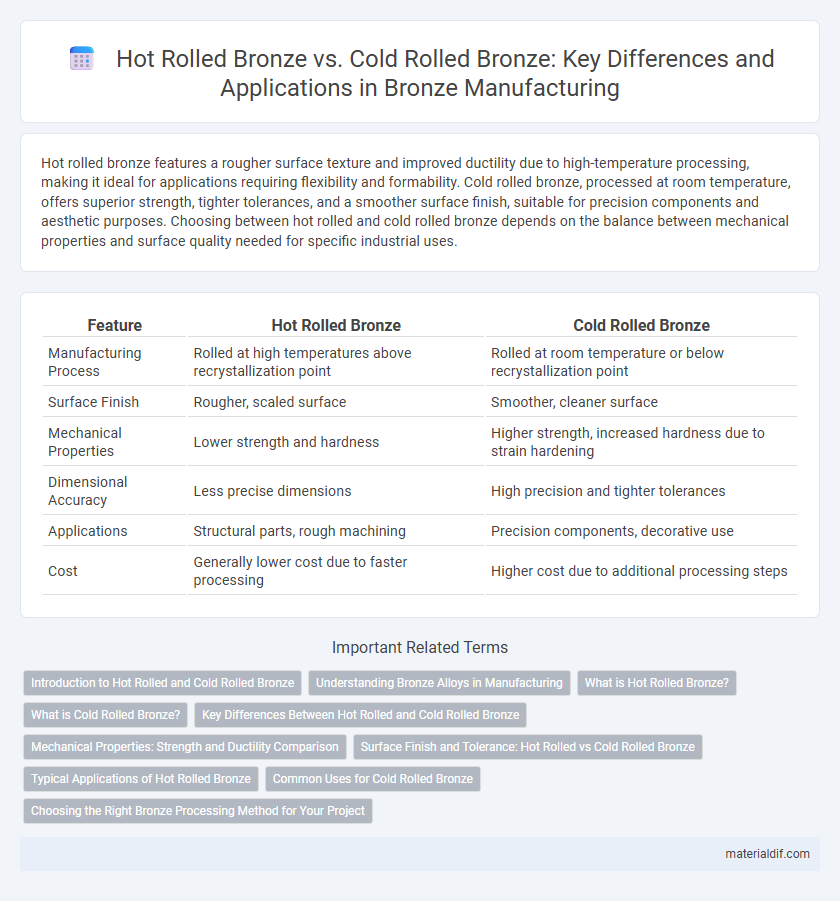

Hot rolled bronze features a rougher surface texture and improved ductility due to high-temperature processing, making it ideal for applications requiring flexibility and formability. Cold rolled bronze, processed at room temperature, offers superior strength, tighter tolerances, and a smoother surface finish, suitable for precision components and aesthetic purposes. Choosing between hot rolled and cold rolled bronze depends on the balance between mechanical properties and surface quality needed for specific industrial uses.

Table of Comparison

| Feature | Hot Rolled Bronze | Cold Rolled Bronze |

|---|---|---|

| Manufacturing Process | Rolled at high temperatures above recrystallization point | Rolled at room temperature or below recrystallization point |

| Surface Finish | Rougher, scaled surface | Smoother, cleaner surface |

| Mechanical Properties | Lower strength and hardness | Higher strength, increased hardness due to strain hardening |

| Dimensional Accuracy | Less precise dimensions | High precision and tighter tolerances |

| Applications | Structural parts, rough machining | Precision components, decorative use |

| Cost | Generally lower cost due to faster processing | Higher cost due to additional processing steps |

Introduction to Hot Rolled and Cold Rolled Bronze

Hot rolled bronze undergoes processing at high temperatures, typically above 1,700degF, which enhances its malleability and reduces internal stresses, resulting in a coarser surface finish and increased ductility. Cold rolled bronze is processed below the recrystallization temperature, producing a smoother surface finish with tighter dimensional tolerances and improved mechanical strength due to strain hardening. The choice between hot rolled and cold rolled bronze depends on specific application requirements, including surface quality, strength, and fabrication needs.

Understanding Bronze Alloys in Manufacturing

Hot rolled bronze features a textured surface and enhanced ductility due to being processed at high temperatures, making it ideal for structural applications requiring flexibility. Cold rolled bronze undergoes deformation at room temperature, resulting in a smoother finish and increased strength, suitable for precision components and decorative uses. Selecting the appropriate bronze alloy and rolling method in manufacturing depends on the desired mechanical properties and surface characteristics.

What is Hot Rolled Bronze?

Hot rolled bronze is a metal alloy processed at high temperatures above its recrystallization point, allowing for easier shaping and forming. This method results in a material with a rougher surface finish and improved ductility compared to cold rolled bronze. Hot rolled bronze is commonly used in applications requiring enhanced malleability and reduced internal stresses.

What is Cold Rolled Bronze?

Cold rolled bronze is a type of bronze alloy processed at room temperature, resulting in a smoother surface finish and improved dimensional accuracy compared to hot rolled bronze. This method enhances the strength and hardness of the metal through strain hardening while maintaining better corrosion resistance. Commonly used in precision applications, cold rolled bronze offers superior mechanical properties for components requiring tight tolerances.

Key Differences Between Hot Rolled and Cold Rolled Bronze

Hot rolled bronze undergoes processing at high temperatures above its recrystallization point, resulting in a rougher surface finish and increased malleability, making it suitable for structural applications. Cold rolled bronze is processed at or near room temperature, enhancing its surface smoothness, dimensional accuracy, and mechanical strength due to strain hardening. The key differences lie in surface texture, mechanical properties, and suitable applications, with hot rolled bronze favored for heavy-duty uses and cold rolled bronze preferred for precision components.

Mechanical Properties: Strength and Ductility Comparison

Hot rolled bronze exhibits reduced strength but enhanced ductility due to its higher processing temperature causing grain growth and softer microstructure. Cold rolled bronze increases strength and hardness through strain hardening while reducing ductility, resulting from work-induced dislocation density. Comparing mechanical properties, hot rolled bronze suits applications requiring formability, whereas cold rolled bronze is preferred for high-strength, wear-resistant components.

Surface Finish and Tolerance: Hot Rolled vs Cold Rolled Bronze

Hot rolled bronze features a rougher surface finish due to the high-temperature deformation process, resulting in less precise dimensions and wider tolerances ideal for applications where surface smoothness is not critical. Cold rolled bronze undergoes a room temperature rolling process that produces a smoother, more polished surface finish with tighter dimensional tolerances, suitable for precision-engineered components. The choice between hot rolled and cold rolled bronze significantly impacts the material's suitability for aesthetic requirements and mechanical fit accuracy in manufacturing.

Typical Applications of Hot Rolled Bronze

Hot rolled bronze is commonly used in heavy-duty applications such as construction, automotive components, and industrial machinery due to its improved toughness and scalability. It is ideal for structural parts, large bronze sheets, and components requiring high strength and moderate surface finish. Typical industries relying on hot rolled bronze include shipbuilding, electrical equipment manufacturing, and architectural design for durable decorative elements.

Common Uses for Cold Rolled Bronze

Cold rolled bronze is commonly used in precision applications such as electrical connectors, mechanical components, and decorative architectural elements due to its superior surface finish and dimensional accuracy. The cold rolling process enhances the strength and hardness of bronze, making it ideal for use in bearings, gears, and wear-resistant components. Its smooth surface and uniform thickness also make it suitable for fine jewelry and intricate metalwork where detailed craftsmanship is essential.

Choosing the Right Bronze Processing Method for Your Project

Hot rolled bronze features enhanced ductility and is ideal for large-scale projects requiring thicker sheets and improved workability, while cold rolled bronze offers superior surface finish and tighter dimensional tolerances suitable for precision components and aesthetic applications. Selecting the right bronze processing method depends on project requirements such as mechanical properties, surface quality, and production scale. Hot rolling reduces internal stresses, making it preferable for structural uses, whereas cold rolling increases material hardness, benefiting wear-resistant parts.

Hot Rolled Bronze vs Cold Rolled Bronze Infographic

materialdif.com

materialdif.com