Art bronze typically emphasizes intricate detailing, fine textures, and aesthetic appeal, often used for sculptures and decorative objects. Architectural bronze prioritizes durability, corrosion resistance, and structural integrity for applications such as doors, railings, and facades. Both use similar alloys but differ in formulation and finishing techniques to suit their specific functional and visual requirements.

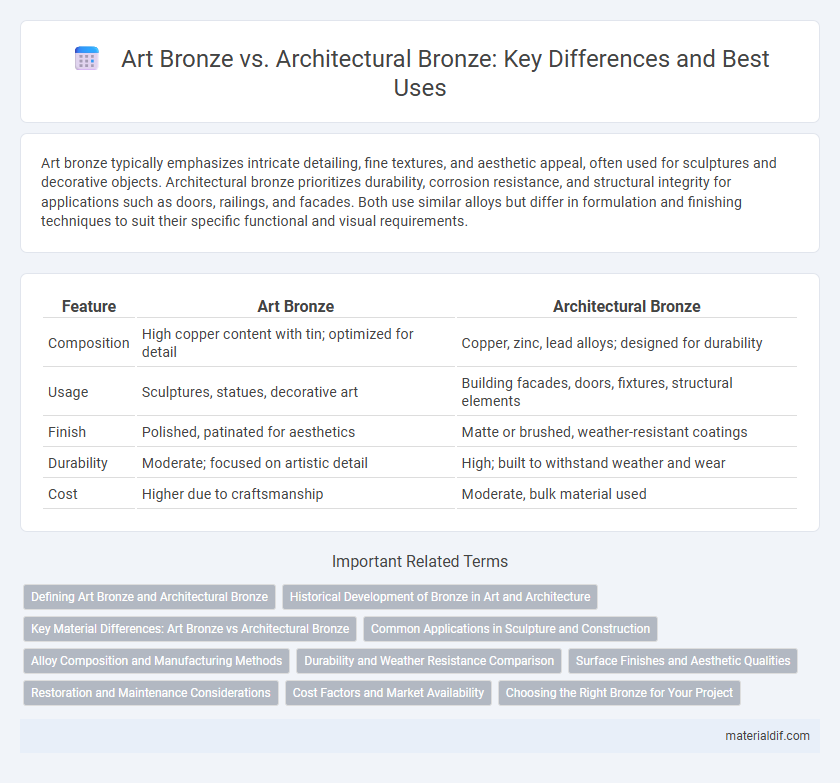

Table of Comparison

| Feature | Art Bronze | Architectural Bronze |

|---|---|---|

| Composition | High copper content with tin; optimized for detail | Copper, zinc, lead alloys; designed for durability |

| Usage | Sculptures, statues, decorative art | Building facades, doors, fixtures, structural elements |

| Finish | Polished, patinated for aesthetics | Matte or brushed, weather-resistant coatings |

| Durability | Moderate; focused on artistic detail | High; built to withstand weather and wear |

| Cost | Higher due to craftsmanship | Moderate, bulk material used |

Defining Art Bronze and Architectural Bronze

Art bronze is a specialized alloy primarily used for sculptural works, characterized by its fine grain, superior casting properties, and rich patina development suitable for detailed artistic expression. Architectural bronze, in contrast, emphasizes durability and corrosion resistance, formulated for structural applications in building facades, doors, and hardware, meeting stringent standards for weather resistance and mechanical strength. Both types of bronze leverage copper-tin alloys but differ in composition and finish to cater to their distinct functional and aesthetic requirements.

Historical Development of Bronze in Art and Architecture

Bronze has been a pivotal material in both art and architecture since ancient civilizations, with sculptors utilizing its durability and malleability for intricate statues and decorative artworks. In contrast, architectural bronze evolved primarily as a material for structural and ornamental applications such as doors, railings, and fixtures, highlighting advancements in metallurgy and urban development from the Renaissance to modern times. The historical development of bronze in art reflects cultural expression and craftsmanship, while its architectural use underscores functionality combined with aesthetic enhancement.

Key Material Differences: Art Bronze vs Architectural Bronze

Art bronze typically contains a higher percentage of copper and tin, creating a finer grain structure that enhances detailed sculpting and surface texture. Architectural bronze features increased amounts of zinc and lead to improve durability, corrosion resistance, and machinability for structural applications. These compositional variances directly influence their mechanical properties, with art bronze favoring aesthetic detail and architectural bronze prioritizing strength and longevity.

Common Applications in Sculpture and Construction

Art bronze is renowned for its use in intricate sculptures, statues, and fine art pieces, favored for its ability to capture detailed textures and withstand outdoor elements. Architectural bronze, characterized by its higher strength and corrosion resistance, is commonly applied in building components such as doors, window frames, railings, and decorative panels. Both types leverage bronze's durability and aesthetic appeal, with art bronze emphasizing artistic expression and architectural bronze prioritizing functional structural uses.

Alloy Composition and Manufacturing Methods

Art bronze typically features a higher copper content combined with tin and small amounts of other metals like zinc and lead, enhancing its malleability and fine detail reproduction for sculptures. Architectural bronze contains a more balanced alloy composition, often including higher percentages of zinc for increased strength and corrosion resistance, making it ideal for structural and decorative building components. Manufacturing methods for art bronze utilize investment casting to capture intricate designs, while architectural bronze is commonly produced through sand casting or extrusion for larger, more durable elements.

Durability and Weather Resistance Comparison

Art bronze typically features a higher copper content and a finer grain structure, enhancing its aesthetic appeal but making it less resistant to harsh weather conditions. Architectural bronze is engineered with durability in mind, boasting superior corrosion resistance and the ability to withstand prolonged exposure to outdoor elements like rain, humidity, and temperature fluctuations. This makes architectural bronze more suitable for exterior applications requiring long-term weather resistance and structural integrity.

Surface Finishes and Aesthetic Qualities

Art bronze typically features patinated or polished surface finishes that emphasize intricate details and rich textures, enhancing its visual appeal and depth. Architectural bronze often employs brushed or anodized finishes designed for durability and corrosion resistance, providing a sleek, uniform aesthetic suited for exterior applications. The contrasting surface treatments result in art bronze showcasing expressive, tactile qualities, while architectural bronze emphasizes functional elegance and long-lasting beauty.

Restoration and Maintenance Considerations

Art bronze requires careful restoration techniques to preserve intricate details and patinas, often involving gentle cleaning and specialized wax coatings to prevent corrosion. Architectural bronze, exposed to harsher environmental conditions, demands robust maintenance protocols including regular inspections, cleaning with mild detergents, and protective sealants to withstand weathering. Both types benefit from expert conservation practices, but architectural bronze restoration prioritizes durability and structural integrity over fine artistic preservation.

Cost Factors and Market Availability

Art bronze, characterized by its high-quality alloy composition and fine craftsmanship, typically commands higher prices due to the intricate casting processes and limited edition production. Architectural bronze, often used in construction and design, prioritizes durability and corrosion resistance, resulting in larger-scale, standardized manufacturing that generally lowers cost per unit. Market availability for art bronze is more specialized and niche, with limited suppliers focused on artistic applications, whereas architectural bronze enjoys broader distribution channels and consistent supply in construction markets.

Choosing the Right Bronze for Your Project

Art bronze offers superior detail and a smoother finish, ideal for sculptures and decorative pieces requiring intricate craftsmanship, while architectural bronze provides enhanced durability and corrosion resistance, suited for structural applications like doors, railings, and hardware. Selecting the right bronze depends on the project's exposure to environmental elements, design complexity, and required longevity, with art bronze favoring aesthetic appeal and architectural bronze prioritizing functionality and strength. Understanding the alloy composition, such as tin and copper content, helps optimize performance tailored to artistic expression or architectural sustainability.

Art Bronze vs Architectural Bronze Infographic

materialdif.com

materialdif.com