Forged bronze exhibits superior strength and durability due to the metal's grain structure being aligned during the forging process, making it ideal for applications requiring high mechanical performance. Cast bronze, shaped by pouring molten metal into molds, allows for intricate designs and complex shapes but may have less tensile strength compared to forged bronze. Choosing between forged and cast bronze depends on whether mechanical strength or detailed design is the priority in the final product.

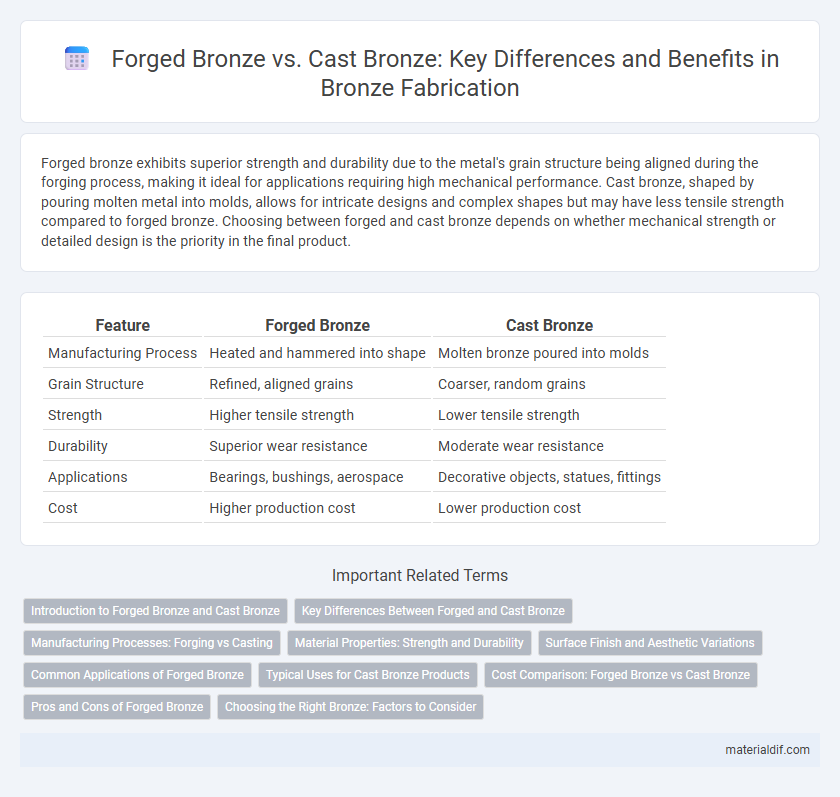

Table of Comparison

| Feature | Forged Bronze | Cast Bronze |

|---|---|---|

| Manufacturing Process | Heated and hammered into shape | Molten bronze poured into molds |

| Grain Structure | Refined, aligned grains | Coarser, random grains |

| Strength | Higher tensile strength | Lower tensile strength |

| Durability | Superior wear resistance | Moderate wear resistance |

| Applications | Bearings, bushings, aerospace | Decorative objects, statues, fittings |

| Cost | Higher production cost | Lower production cost |

Introduction to Forged Bronze and Cast Bronze

Forged bronze is created by shaping heated bronze through hammering or pressing, resulting in a dense, strong material with enhanced mechanical properties. Cast bronze is produced by pouring molten bronze into a mold, allowing for complex shapes but often with slightly lower tensile strength compared to forged bronze. Both methods utilize bronze's copper-tin alloy composition, but forged bronze offers superior durability for high-stress applications, while cast bronze excels in intricate designs.

Key Differences Between Forged and Cast Bronze

Forged bronze is produced by shaping heated bronze through hammering or pressing, resulting in a denser and more durable material with enhanced tensile strength. Cast bronze is created by pouring molten bronze into molds, allowing for complex shapes but often with less uniform grain structure and potential porosity. The key differences lie in the manufacturing process, material density, mechanical properties, and suitability for precision versus large-scale production.

Manufacturing Processes: Forging vs Casting

Forged bronze undergoes a manufacturing process where heated metal is compressed and shaped using high pressure, resulting in a dense, strong material with enhanced structural integrity. Cast bronze is produced by melting bronze alloys and pouring the liquid metal into molds, allowing for complex shapes but sometimes leading to porosity or internal defects. The forging process minimizes grain boundaries and improves mechanical properties, whereas casting offers versatility in design but may require additional treatments to achieve similar strength.

Material Properties: Strength and Durability

Forged bronze exhibits superior strength and durability compared to cast bronze due to its denser microstructure formed under high pressure, resulting in enhanced resistance to fatigue and impact. Cast bronze, while easier to shape and more cost-effective, tends to have a more porous internal structure that can reduce mechanical strength and increase susceptibility to cracks over time. The choice between forged and cast bronze depends on the application requirements, with forged bronze preferred for high-stress environments demanding maximum toughness.

Surface Finish and Aesthetic Variations

Forged bronze typically exhibits a smoother, more uniform surface finish due to the controlled hammering and shaping process, enhancing its aesthetic appeal with fine grain detail and subtle textures. Cast bronze offers greater versatility in surface finishes, allowing for intricate patterns and varied textures from the mold, resulting in diverse artistic effects but sometimes with minor imperfections or roughness inherent to casting methods. The choice between forged and cast bronze depends on the desired balance between precision surface quality and complex design aesthetics.

Common Applications of Forged Bronze

Forged bronze is widely used in applications requiring superior strength and durability, such as marine hardware, bearing components, and aerospace fittings. Its enhanced grain structure results in improved mechanical properties, making it ideal for high-stress environments. Common applications include valves, gears, and fasteners where resistance to wear and corrosion is critical.

Typical Uses for Cast Bronze Products

Cast bronze products are commonly used in applications requiring complex shapes and excellent corrosion resistance, such as marine hardware, sculptures, and industrial machinery components. Their superior casting properties allow for detailed designs and durability in harsh environments. Typical uses also include valve bodies, bearings, and pump components where strength and wear resistance are critical.

Cost Comparison: Forged Bronze vs Cast Bronze

Forged bronze typically incurs higher production costs due to the labor-intensive process that involves shaping metal under high pressure, resulting in superior strength and durability. Cast bronze offers a more cost-effective solution because the molten metal is poured into molds, allowing for complex shapes and higher volume production with reduced labor expenses. When comparing costs, cast bronze is generally favored for large-scale or intricate designs, while forged bronze is preferred for applications demanding enhanced mechanical properties despite its higher price.

Pros and Cons of Forged Bronze

Forged bronze offers superior strength and durability due to its refined grain structure created by the forging process, making it ideal for high-stress applications. However, forged bronze typically involves higher production costs and is limited in the complexity of shapes it can achieve compared to cast bronze. Its enhanced mechanical properties provide better wear resistance and toughness, while cast bronze excels in producing intricate designs at a lower cost.

Choosing the Right Bronze: Factors to Consider

Selecting between forged bronze and cast bronze depends on factors such as mechanical strength, precision, and application requirements. Forged bronze offers superior tensile strength and durability, ideal for high-stress components like bearings and gears. Cast bronze provides excellent moldability and intricate detail, making it suitable for decorative elements and complex shapes.

Forged Bronze vs Cast Bronze Infographic

materialdif.com

materialdif.com