Hot working of bronze involves shaping the metal above its recrystallization temperature, enhancing ductility and reducing the risk of work hardening, which allows for significant deformation without cracking. Cold working, performed at or near room temperature, increases the strength and hardness of bronze through strain hardening but may cause brittleness and requires subsequent annealing to restore ductility. Choosing between hot and cold working depends on the desired mechanical properties and the complexity of the bronze component.

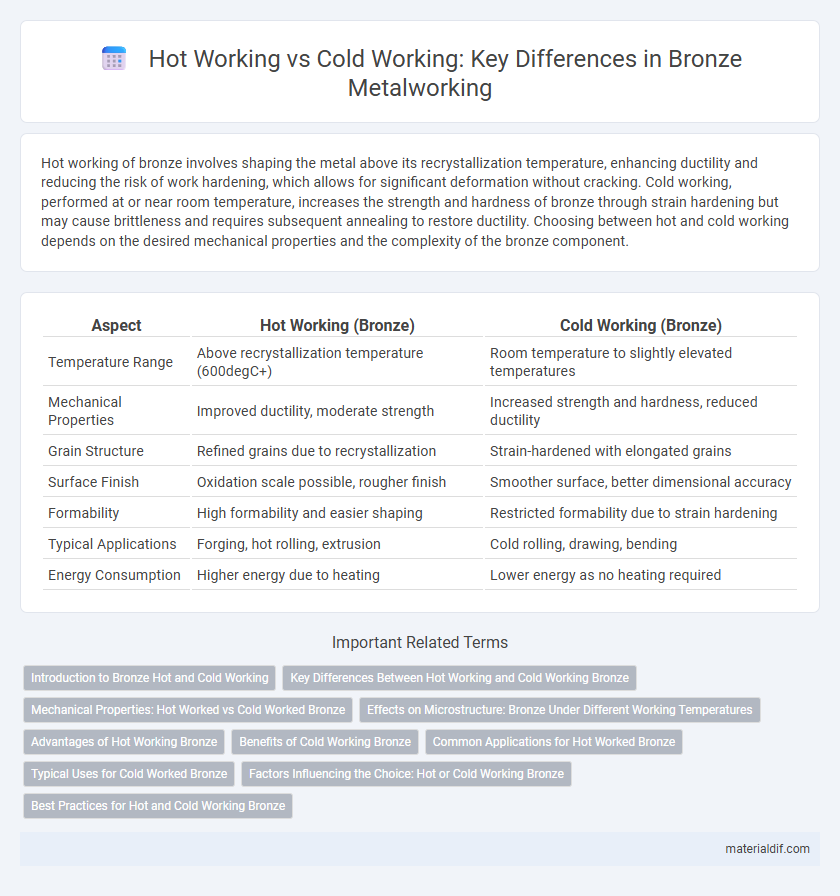

Table of Comparison

| Aspect | Hot Working (Bronze) | Cold Working (Bronze) |

|---|---|---|

| Temperature Range | Above recrystallization temperature (600degC+) | Room temperature to slightly elevated temperatures |

| Mechanical Properties | Improved ductility, moderate strength | Increased strength and hardness, reduced ductility |

| Grain Structure | Refined grains due to recrystallization | Strain-hardened with elongated grains |

| Surface Finish | Oxidation scale possible, rougher finish | Smoother surface, better dimensional accuracy |

| Formability | High formability and easier shaping | Restricted formability due to strain hardening |

| Typical Applications | Forging, hot rolling, extrusion | Cold rolling, drawing, bending |

| Energy Consumption | Higher energy due to heating | Lower energy as no heating required |

Introduction to Bronze Hot and Cold Working

Bronze hot working involves deforming the alloy at temperatures above its recrystallization point, enhancing ductility and reducing the risk of cracking, which is ideal for shaping complex components. Cold working bronze occurs below recrystallization temperatures, increasing strength and hardness through strain hardening but also causing reduced ductility and potential brittleness. Understanding the balance between hot and cold working processes allows precise control over bronze's mechanical properties, optimizing its performance for applications in marine, electrical, and decorative industries.

Key Differences Between Hot Working and Cold Working Bronze

Hot working bronze involves shaping the metal at temperatures above its recrystallization point, enhancing ductility and reducing the risk of strain hardening. Cold working bronze is performed at or near room temperature, increasing strength and hardness through strain hardening but reducing ductility. Hot working typically allows greater deformation without cracking, while cold working produces finer surface finishes and improved mechanical properties.

Mechanical Properties: Hot Worked vs Cold Worked Bronze

Hot worked bronze exhibits improved ductility and reduced strength due to recrystallization occurring at elevated temperatures, which refines grain structure and alleviates internal stresses. Cold worked bronze demonstrates increased tensile strength and hardness resulting from strain hardening, though it has lower ductility and higher residual stress compared to hot worked counterparts. Mechanical properties of cold worked bronze are ideal for applications requiring enhanced strength, while hot worked bronze suits scenarios demanding better formability and toughness.

Effects on Microstructure: Bronze Under Different Working Temperatures

Hot working of bronze occurs above its recrystallization temperature, leading to dynamic recrystallization that refines grains and eliminates work hardening, resulting in a more uniform and ductile microstructure. Cold working bronze below its recrystallization point induces strain hardening, creating elongated grains and increased dislocation density, which enhances strength but reduces ductility. The temperature of deformation critically influences grain size, dislocation density, and phase distribution, thereby affecting mechanical properties and corrosion resistance in bronze alloys.

Advantages of Hot Working Bronze

Hot working bronze significantly improves its ductility and reduces the risk of cracking by maintaining the material above its recrystallization temperature during deformation. This process enhances the metal's grain structure, leading to superior formability and mechanical properties compared to cold working. Hot working also enables the creation of complex shapes with reduced residual stresses and improved dimensional stability.

Benefits of Cold Working Bronze

Cold working bronze enhances its tensile strength and hardness through strain hardening, improving wear resistance and durability in applications requiring precision and toughness. This process also refines the metal's surface finish, reducing the need for extensive machining and lowering fabrication costs. Retaining the inherent corrosion resistance of bronze, cold working ensures long-lasting performance in marine, electrical, and decorative uses.

Common Applications for Hot Worked Bronze

Hot worked bronze is commonly used in applications requiring enhanced ductility and improved mechanical properties, such as heavy-duty bearings, marine hardware, and architectural components. The hot working process refines the grain structure, making bronze suitable for complex shapes like pipes, rods, and sheets used in electrical connectors and sculptures. This method also reduces residual stresses, providing superior corrosion resistance vital for marine and industrial environments.

Typical Uses for Cold Worked Bronze

Cold worked bronze is typically used in applications requiring enhanced strength, wear resistance, and dimensional stability without the need for further heat treatment. Common uses include electrical connectors, springs, and gears where precision and durability are critical, as the cold working process refines the grain structure and improves mechanical properties. This form of bronze excels in environments demanding improved fatigue resistance and corrosion performance.

Factors Influencing the Choice: Hot or Cold Working Bronze

The choice between hot working and cold working bronze depends on factors such as alloy composition, desired mechanical properties, and final application requirements. Hot working is preferred for bronze with higher alloy content that requires significant deformation and improved ductility, while cold working is suitable for applications demanding enhanced surface finish and dimensional accuracy. Temperature sensitivity, grain structure control, and strain hardening effects also play crucial roles in determining the optimal working process for bronze components.

Best Practices for Hot and Cold Working Bronze

Hot working bronze involves heating the alloy above its recrystallization temperature, typically between 700degC and 900degC, to improve ductility and reduce the risk of cracking during deformation. Cold working bronze at room temperature enhances strength and hardness through strain hardening but requires periodic annealing to restore ductility and prevent brittle fracture. Best practices include selecting the appropriate working temperature based on alloy composition and desired mechanical properties, ensuring gradual deformation rates during hot working, and implementing controlled annealing cycles after cold working to optimize performance and longevity.

Hot Working vs Cold Working (Bronze) Infographic

materialdif.com

materialdif.com