Pressed bronze is created by compressing bronze powder under high pressure, resulting in a dense and durable material with excellent dimensional accuracy. Sintered bronze involves heating bronze powder below its melting point to bond particles, producing a porous structure ideal for self-lubricating bearings and improved fluid retention. The choice between pressed and sintered bronze depends on the application's need for strength versus porosity and lubrication.

Table of Comparison

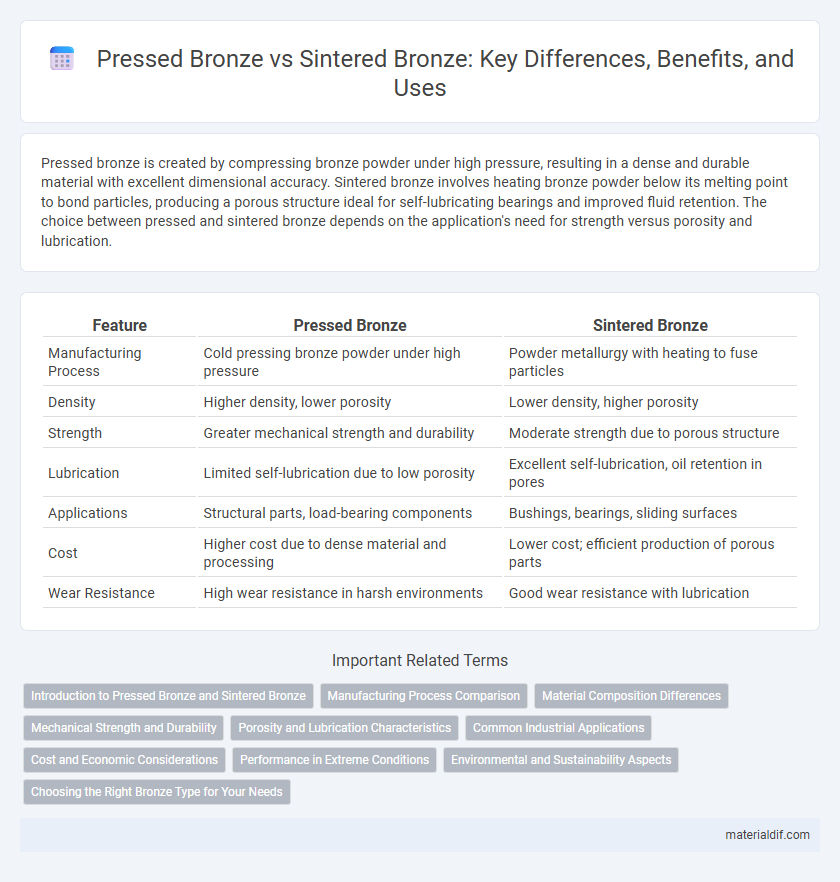

| Feature | Pressed Bronze | Sintered Bronze |

|---|---|---|

| Manufacturing Process | Cold pressing bronze powder under high pressure | Powder metallurgy with heating to fuse particles |

| Density | Higher density, lower porosity | Lower density, higher porosity |

| Strength | Greater mechanical strength and durability | Moderate strength due to porous structure |

| Lubrication | Limited self-lubrication due to low porosity | Excellent self-lubrication, oil retention in pores |

| Applications | Structural parts, load-bearing components | Bushings, bearings, sliding surfaces |

| Cost | Higher cost due to dense material and processing | Lower cost; efficient production of porous parts |

| Wear Resistance | High wear resistance in harsh environments | Good wear resistance with lubrication |

Introduction to Pressed Bronze and Sintered Bronze

Pressed bronze is manufactured by compressing bronze powder into a solid form under high pressure, creating dense components with excellent mechanical strength and wear resistance. Sintered bronze is produced by heating bronze powder below its melting point, allowing particles to fuse, resulting in a porous structure that offers superior lubrication and self-lubricating properties. Both pressed and sintered bronze are widely used in industrial applications for bearings, bushings, and wear-resistant parts, with pressed bronze favored for durability and sintered bronze valued for enhanced lubrication performance.

Manufacturing Process Comparison

Pressed bronze is manufactured by compacting bronze powder under high pressure without melting, producing dense, uniform parts with precise dimensions. Sintered bronze involves heating bronze powder below its melting point to bond particles together, resulting in porous components ideal for self-lubricating applications. The pressed process yields stronger, less porous products, while sintering offers enhanced permeability and abrasion resistance due to controlled porosity.

Material Composition Differences

Pressed bronze consists of finely powdered copper and tin particles compacted under high pressure without melting, resulting in a dense, homogenous material with minimal porosity. Sintered bronze is produced by heating powdered bronze below its melting point to fuse particles together, creating a porous structure that can retain lubricants for improved wear resistance. The key material composition difference lies in the processing method, where pressed bronze achieves solid density with uniform microstructure while sintered bronze contains controlled porosity for enhanced self-lubricating properties.

Mechanical Strength and Durability

Pressed bronze offers higher mechanical strength due to its dense, compact structure formed under high pressure, making it ideal for applications demanding robust load-bearing capabilities. Sintered bronze, created through powder metallurgy with controlled porosity, provides excellent durability through enhanced wear resistance and self-lubricating properties but generally exhibits lower mechanical strength compared to pressed bronze. Selecting between pressed and sintered bronze depends on balancing requirements for strength versus durability in specific engineering contexts.

Porosity and Lubrication Characteristics

Pressed bronze exhibits lower porosity due to the compacting process, resulting in a denser and stronger material with reduced oil absorption. Sintered bronze, characterized by higher porosity from the powder metallurgy sintering method, provides enhanced lubrication retention, making it ideal for self-lubricating bearing applications. The increased porosity in sintered bronze allows for better oil impregnation and distribution during operation, improving wear resistance in dynamic environments.

Common Industrial Applications

Pressed bronze, known for its high density and durability, is commonly used in automotive components, electrical connectors, and bearing applications where strength and conductivity are critical. Sintered bronze, with its porous structure, excels in self-lubricating bearings, bushings, and filters, making it ideal for machinery requiring reduced friction and maintenance. Both materials play key roles in manufacturing industries, balancing performance needs with cost-effective production.

Cost and Economic Considerations

Pressed bronze generally offers lower manufacturing costs due to its simpler production process involving shaping bronze powder under high pressure without requiring high-temperature sintering. Sintered bronze, while more expensive because of the energy-intensive heating stage that fuses particles for enhanced strength and porosity control, can provide superior durability, potentially lowering long-term maintenance expenses. Choosing between pressed and sintered bronze depends on balancing initial budget constraints with performance needs and lifecycle cost efficiency.

Performance in Extreme Conditions

Pressed bronze exhibits superior durability and structural integrity under high-pressure applications, making it ideal for heavy-duty use in extreme environments. Sintered bronze offers enhanced porosity, enabling self-lubrication and better heat dissipation, which improves performance in high-temperature and abrasive conditions. The choice between pressed and sintered bronze depends on the specific demands of the application, such as load capacity and thermal resistance requirements.

Environmental and Sustainability Aspects

Pressed bronze production typically consumes less energy than sintered bronze processes, reducing its environmental footprint. Sintered bronze involves powdered metal consolidation under heat, which can emit higher greenhouse gases but allows for precise material usage and waste reduction. Both methods support sustainability by enabling recyclable components, though pressed bronze offers a more energy-efficient manufacturing route.

Choosing the Right Bronze Type for Your Needs

Pressed bronze offers high density and strength, making it ideal for applications requiring durability and load-bearing capacity. Sintered bronze provides superior porosity and self-lubricating properties, suited for low-friction environments and maintenance-free bearings. Selecting the right bronze type depends on whether your priority is structural strength or enhanced lubrication performance.

Pressed Bronze vs Sintered Bronze Infographic

materialdif.com

materialdif.com