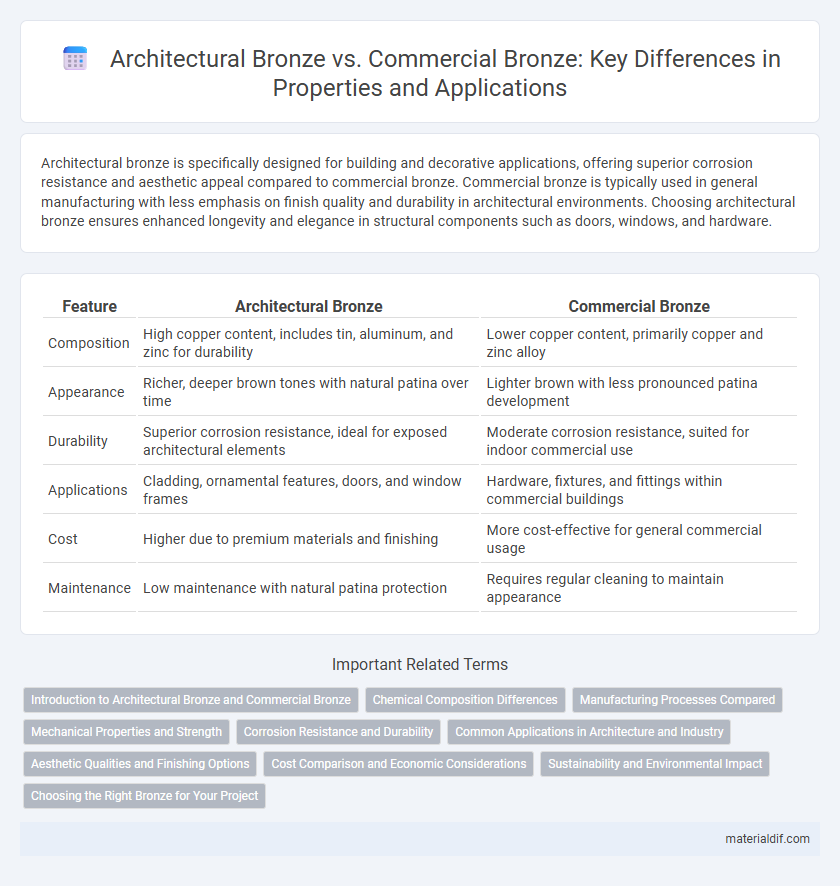

Architectural bronze is specifically designed for building and decorative applications, offering superior corrosion resistance and aesthetic appeal compared to commercial bronze. Commercial bronze is typically used in general manufacturing with less emphasis on finish quality and durability in architectural environments. Choosing architectural bronze ensures enhanced longevity and elegance in structural components such as doors, windows, and hardware.

Table of Comparison

| Feature | Architectural Bronze | Commercial Bronze |

|---|---|---|

| Composition | High copper content, includes tin, aluminum, and zinc for durability | Lower copper content, primarily copper and zinc alloy |

| Appearance | Richer, deeper brown tones with natural patina over time | Lighter brown with less pronounced patina development |

| Durability | Superior corrosion resistance, ideal for exposed architectural elements | Moderate corrosion resistance, suited for indoor commercial use |

| Applications | Cladding, ornamental features, doors, and window frames | Hardware, fixtures, and fittings within commercial buildings |

| Cost | Higher due to premium materials and finishing | More cost-effective for general commercial usage |

| Maintenance | Low maintenance with natural patina protection | Requires regular cleaning to maintain appearance |

Introduction to Architectural Bronze and Commercial Bronze

Architectural bronze, prized for its durability and rich, warm tones, is primarily used in building facades, doors, and decorative elements, blending aesthetic appeal with structural strength. Commercial bronze, often alloyed with other metals for enhanced corrosion resistance and lower cost, is commonly utilized in hardware, fixtures, and tools where functional performance is critical. Understanding the distinct alloy compositions and applications of architectural versus commercial bronze helps in selecting the ideal material for design and performance requirements.

Chemical Composition Differences

Architectural bronze typically features a higher copper content, often around 90%, combined with smaller amounts of tin and trace elements to optimize corrosion resistance and aesthetic appeal. Commercial bronze, in contrast, contains a more varied alloy composition, including higher proportions of zinc and lead to enhance machinability and reduce manufacturing costs. These chemical composition differences influence the durability, finish, and suitability of each bronze type for specific architectural or industrial applications.

Manufacturing Processes Compared

Architectural bronze is typically produced using high-purity alloys with precise casting and machining techniques to ensure superior durability and aesthetic appeal, while commercial bronze often involves more cost-effective manufacturing methods such as sand casting or extrusion. The refined manufacturing process of architectural bronze results in enhanced corrosion resistance and a smoother finish critical for premium architectural applications. Conversely, commercial bronze prioritizes bulk production efficiency over fine surface quality and alloy uniformity.

Mechanical Properties and Strength

Architectural bronze typically exhibits higher tensile strength and superior corrosion resistance compared to commercial bronze, making it ideal for structural applications exposed to environmental stress. Mechanical properties such as yield strength and hardness in architectural bronze are optimized for durability and long-term stability in building facades and fittings. Commercial bronze, while still strong, generally has lower mechanical strength and is more suited for ornamental or low-stress functional components.

Corrosion Resistance and Durability

Architectural bronze exhibits superior corrosion resistance and durability compared to commercial bronze due to its higher copper and tin content, which enhances its ability to withstand environmental exposure and weathering. This makes architectural bronze ideal for exterior applications such as building facades, window frames, and ornamental elements where long-term performance against oxidation and patina formation is critical. Commercial bronze, with a lower copper concentration, is generally more prone to corrosion and wear, suited for indoor or less demanding environments.

Common Applications in Architecture and Industry

Architectural bronze is commonly used in building facades, doorframes, and decorative elements due to its aesthetic appeal and corrosion resistance, making it ideal for exterior and interior design in commercial and residential constructions. Commercial bronze finds extensive application in industrial components such as gears, bearings, and bushings, where durability and wear resistance are critical for machinery and manufacturing processes. Both types of bronze offer unique properties tailored to their respective uses, with architectural bronze emphasizing appearance and environmental resilience, while commercial bronze prioritizes mechanical strength and longevity.

Aesthetic Qualities and Finishing Options

Architectural bronze features a warmer, reddish-brown hue due to its higher copper content, offering rich aesthetic appeal ideal for decorative applications in building facades and interior accents. Commercial bronze, often alloyed with higher amounts of zinc and tin, presents a more utilitarian appearance with a matte or satin finish suited for functional hardware and fixtures. Finishing options for architectural bronze include hand-rubbed patinas and clear lacquers to enhance its natural luster, while commercial bronze commonly receives standard powder coating or plating for durability and corrosion resistance.

Cost Comparison and Economic Considerations

Architectural bronze typically costs 20-30% more than commercial bronze due to its higher purity, superior corrosion resistance, and enhanced finish quality, making it ideal for premium construction projects. Commercial bronze offers a more economical alternative with adequate strength and durability for standard applications, reducing upfront material expenses. Economic considerations favor commercial bronze for budget-conscious projects, while architectural bronze provides long-term value through improved longevity and reduced maintenance costs.

Sustainability and Environmental Impact

Architectural bronze, composed primarily of copper and tin, offers superior corrosion resistance and durability, enhancing building longevity and reducing the need for frequent replacements, which contributes to environmental sustainability. Commercial bronze, often containing additional elements like zinc or lead, may compromise recyclability and increase environmental footprint during manufacturing. Choosing architectural bronze supports eco-friendly construction practices by minimizing waste and promoting material reuse in sustainable architectural designs.

Choosing the Right Bronze for Your Project

Architectural bronze offers enhanced durability, corrosion resistance, and aesthetic appeal, making it ideal for high-end building facades, decorative accents, and custom designs. Commercial bronze, typically used for utilitarian fixtures and hardware, prioritizes cost-effectiveness and functional strength over intricate finishes. Selecting the right bronze requires evaluating project requirements, exposure conditions, and desired visual impact to ensure long-lasting performance and maintain design integrity.

Architectural Bronze vs Commercial Bronze Infographic

materialdif.com

materialdif.com