Manganese bronze is an alloy known for its high strength and corrosion resistance, making it ideal for marine and industrial applications, while nickel bronze offers superior resistance to wear and tarnishing, commonly used in decorative and architectural elements. The presence of manganese enhances the hardness and toughness of the alloy, whereas nickel contributes to improved ductility and a brighter finish. Choosing between manganese bronze and nickel bronze depends on the balance needed between mechanical strength and aesthetic appeal.

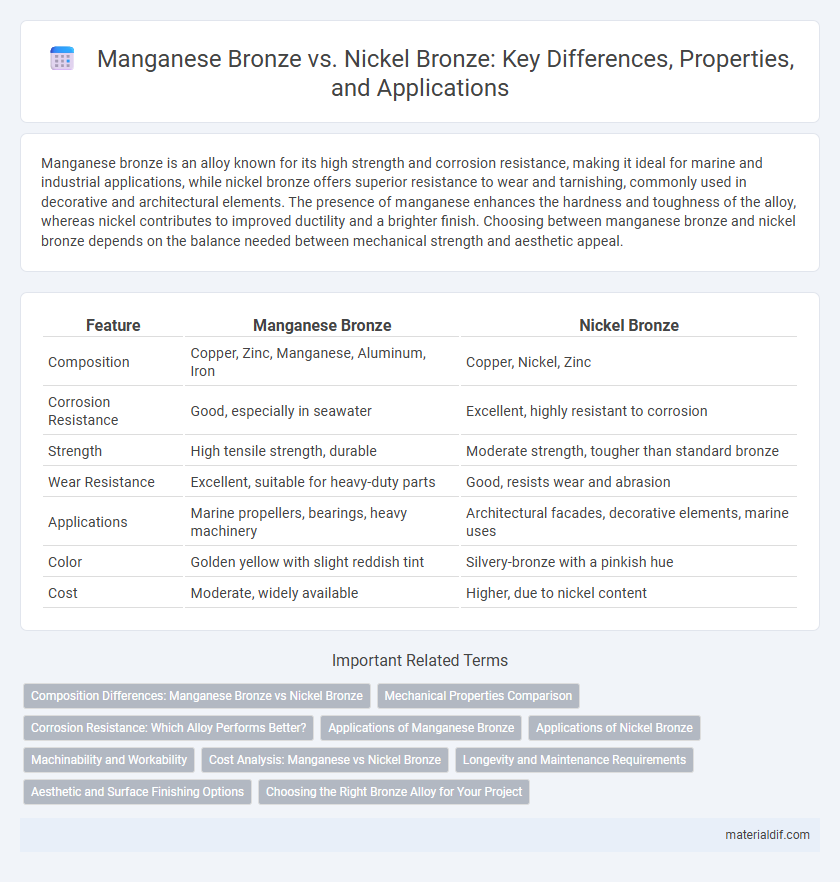

Table of Comparison

| Feature | Manganese Bronze | Nickel Bronze |

|---|---|---|

| Composition | Copper, Zinc, Manganese, Aluminum, Iron | Copper, Nickel, Zinc |

| Corrosion Resistance | Good, especially in seawater | Excellent, highly resistant to corrosion |

| Strength | High tensile strength, durable | Moderate strength, tougher than standard bronze |

| Wear Resistance | Excellent, suitable for heavy-duty parts | Good, resists wear and abrasion |

| Applications | Marine propellers, bearings, heavy machinery | Architectural facades, decorative elements, marine uses |

| Color | Golden yellow with slight reddish tint | Silvery-bronze with a pinkish hue |

| Cost | Moderate, widely available | Higher, due to nickel content |

Composition Differences: Manganese Bronze vs Nickel Bronze

Manganese bronze primarily consists of copper combined with around 5-7% manganese, along with small amounts of aluminum, iron, and zinc, which enhances its strength and corrosion resistance. Nickel bronze, on the other hand, features copper alloyed with approximately 5-12% nickel, often including zinc and iron, resulting in superior hardness and wear resistance compared to manganese bronze. These compositional differences influence mechanical properties, with manganese bronze offering excellent fatigue strength and nickel bronze providing improved toughness and resistance to marine corrosion.

Mechanical Properties Comparison

Manganese bronze exhibits superior tensile strength and higher hardness compared to nickel bronze, making it ideal for heavy-load and wear-resistant applications. Nickel bronze offers better corrosion resistance and greater ductility, which enhances its performance in marine and chemical environments. Both alloys combine copper with specific elements but differ significantly in mechanical properties due to manganese's contribution to strength and nickel's influence on corrosion protection.

Corrosion Resistance: Which Alloy Performs Better?

Nickel bronze exhibits superior corrosion resistance compared to manganese bronze, particularly in marine environments due to its higher nickel content that enhances resistance to saltwater and atmospheric corrosion. Manganese bronze, while strong and durable, is more prone to dezincification and surface corrosion when exposed to harsh conditions. The enhanced corrosion resistance of nickel bronze makes it the preferred choice for applications requiring long-term durability in aggressive environments.

Applications of Manganese Bronze

Manganese bronze is widely used in marine applications due to its excellent corrosion resistance and high strength, making it ideal for propellers, pump components, and ship fittings. Its superior wear resistance also suits it for heavy-duty industrial parts such as gears, valves, and bearings. Compared to nickel bronze, manganese bronze offers better toughness and fatigue resistance, enhancing performance in demanding mechanical environments.

Applications of Nickel Bronze

Nickel Bronze exhibits superior corrosion resistance and mechanical strength compared to Manganese Bronze, making it ideal for marine applications such as ship propellers, pump components, and seawater valves. Its enhanced durability in harsh environments also supports its use in architectural elements and heavy-duty industrial machinery. The alloy's excellent machinability and resistance to biofouling extend its performance in demanding operational settings.

Machinability and Workability

Manganese bronze offers superior machinability compared to nickel bronze due to its lower hardness and favorable grain structure, enabling easier cutting, drilling, and shaping. Nickel bronze excels in corrosion resistance and strength but presents more challenges during machining, often requiring specialized tools to maintain precision and surface finish. For applications prioritizing ease of manufacturing and complex forms, manganese bronze is preferred, while nickel bronze suits environments demanding enhanced durability and wear resistance.

Cost Analysis: Manganese vs Nickel Bronze

Manganese bronze offers a lower cost option compared to nickel bronze due to the abundance and lower price of manganese as a raw material. Nickel bronze, while generally more expensive, provides enhanced corrosion resistance and strength, justifying its higher cost in specialized applications. Cost analysis should consider metal market fluctuations, manufacturing processes, and long-term performance when choosing between manganese and nickel bronze alloys.

Longevity and Maintenance Requirements

Manganese bronze offers superior durability with excellent resistance to wear and corrosion, making it ideal for heavy-load applications and extending service life. Nickel bronze provides notable corrosion resistance, especially in marine environments, but generally requires more frequent maintenance to prevent surface degradation. Choosing manganese bronze reduces upkeep costs due to its enhanced strength and longevity compared to nickel bronze.

Aesthetic and Surface Finishing Options

Manganese Bronze offers a warm, golden-brown hue with excellent corrosion resistance, making it ideal for decorative applications requiring a polished, smooth finish. Nickel Bronze, characterized by its silvery-white appearance, provides superior brightness and a cooler tone, which enhances the appeal of intricate surface textures such as brushing or satin finishes. Both alloys enable versatile surface treatments including plating, patination, and lacquering to achieve durable, aesthetic finishes tailored to specific design requirements.

Choosing the Right Bronze Alloy for Your Project

Manganese bronze offers high tensile strength and excellent corrosion resistance, making it ideal for heavy-duty marine and industrial applications. Nickel bronze provides superior aesthetic appeal with enhanced corrosion resistance, suitable for decorative and architectural projects. Selecting the right bronze alloy depends on balancing mechanical strength needs against visual and environmental factors specific to your project's requirements.

Manganese Bronze vs Nickel Bronze Infographic

materialdif.com

materialdif.com