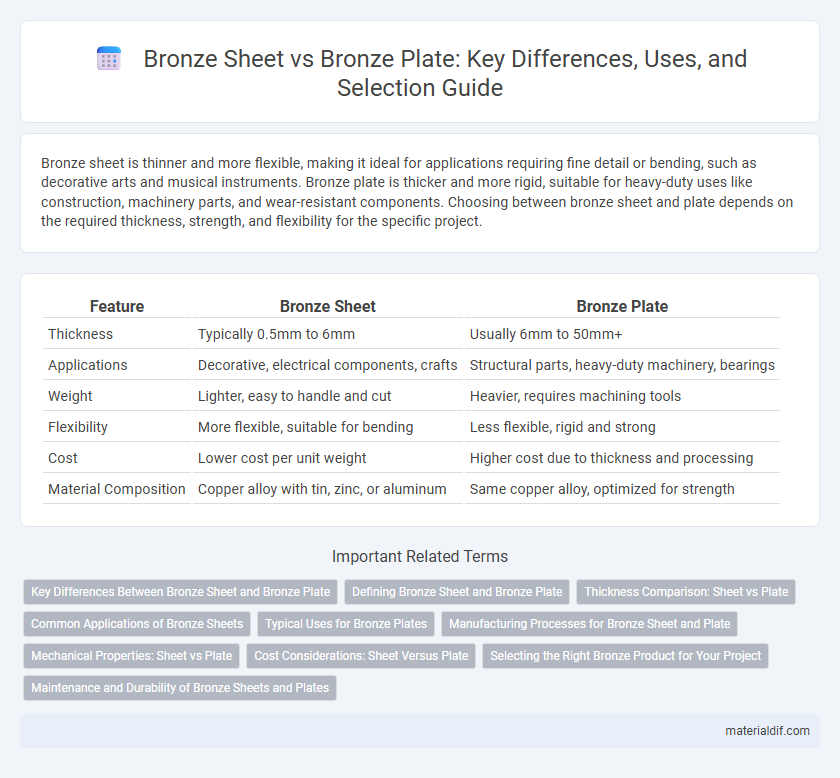

Bronze sheet is thinner and more flexible, making it ideal for applications requiring fine detail or bending, such as decorative arts and musical instruments. Bronze plate is thicker and more rigid, suitable for heavy-duty uses like construction, machinery parts, and wear-resistant components. Choosing between bronze sheet and plate depends on the required thickness, strength, and flexibility for the specific project.

Table of Comparison

| Feature | Bronze Sheet | Bronze Plate |

|---|---|---|

| Thickness | Typically 0.5mm to 6mm | Usually 6mm to 50mm+ |

| Applications | Decorative, electrical components, crafts | Structural parts, heavy-duty machinery, bearings |

| Weight | Lighter, easy to handle and cut | Heavier, requires machining tools |

| Flexibility | More flexible, suitable for bending | Less flexible, rigid and strong |

| Cost | Lower cost per unit weight | Higher cost due to thickness and processing |

| Material Composition | Copper alloy with tin, zinc, or aluminum | Same copper alloy, optimized for strength |

Key Differences Between Bronze Sheet and Bronze Plate

Bronze sheets are thinner, typically measuring less than 3mm in thickness, making them ideal for applications requiring flexibility and intricate metalworking such as decorative panels and electronics. Bronze plates are thicker, generally exceeding 6mm, offering superior strength and durability for structural uses like marine hardware and machinery components. The key difference lies in their thickness and corresponding mechanical properties, influencing their suitability for precision versus heavy-duty applications.

Defining Bronze Sheet and Bronze Plate

Bronze sheets are thin, flat pieces of bronze typically used for decorative applications and fine metalwork due to their flexibility and ease of cutting. Bronze plates are thicker and sturdier, designed for structural and heavy-duty purposes where strength and durability are essential. Both bronze sheets and plates vary in alloy composition, impacting corrosion resistance, hardness, and tensile strength.

Thickness Comparison: Sheet vs Plate

Bronze sheets typically range from 0.2 mm to 6 mm in thickness, making them ideal for applications requiring thin, flexible metal surfaces. Bronze plates are thicker, usually starting at 6 mm and extending beyond 100 mm, providing greater structural strength and durability. The choice between sheet and plate depends on the specific thickness requirements, with sheets favored for lightweight, intricate designs and plates suited for heavy-duty, load-bearing constructions.

Common Applications of Bronze Sheets

Bronze sheets are widely used in architectural applications, marine hardware, and decorative arts due to their excellent corrosion resistance and workability. Unlike thicker bronze plates, sheets provide flexibility suitable for creating intricate designs, cladding, and embossed metalwork. Common applications include roofing, sculptures, and electrical connectors where precise thickness and ease of machining are essential.

Typical Uses for Bronze Plates

Bronze plates are commonly used in industrial applications requiring high durability and corrosion resistance, such as in marine hardware, electrical connectors, and bearing surfaces. Their thickness and strength make them suitable for structural components, heavy-duty machinery, and architectural elements requiring enhanced load-bearing capacity. In contrast, bronze sheets, being thinner, are often utilized for decorative purposes, engraving, and lightweight fabrication tasks.

Manufacturing Processes for Bronze Sheet and Plate

Bronze sheets and plates undergo distinct manufacturing processes tailored to their thickness and end use, with sheets typically produced through rolling or hammering to achieve thin, uniform layers. Plates are generally manufactured using thicker starting billets subjected to hot or cold rolling, followed by annealing to enhance mechanical properties and dimensional stability. Precision in temperature control and deformation rates during these processes ensures optimal grain structure and surface finish in both bronze sheets and plates.

Mechanical Properties: Sheet vs Plate

Bronze sheets typically offer higher tensile strength and better flexibility compared to bronze plates, making them suitable for applications requiring precise forming and bending. Bronze plates, being thicker, provide superior impact resistance and enhanced compressive strength, ideal for heavy-duty structural uses. The mechanical properties of bronze sheets emphasize ductility and surface finish, whereas plates prioritize durability and load-bearing capacity.

Cost Considerations: Sheet Versus Plate

Bronze sheets typically cost less than bronze plates due to their thinner gauge and simpler manufacturing process, making them ideal for applications requiring lightweight material with surface coverage. Bronze plates, being thicker and heavier, generally incur higher material and processing costs but offer superior strength and durability for structural or heavy-duty uses. Cost efficiency depends on project requirements, with sheets favored for budget-sensitive, aesthetic, or light-load applications, while plates justify their expense when mechanical performance is critical.

Selecting the Right Bronze Product for Your Project

Bronze sheets offer thinner dimensions ideal for detailed engraving, decorative uses, and lightweight applications, while bronze plates provide greater thickness and strength suited for structural components, heavy machinery parts, or wear-resistant surfaces. Understanding the specific mechanical properties like tensile strength and corrosion resistance required for your project helps determine if a bronze sheet or plate is more appropriate. Cost considerations and fabrication methods such as cutting or machining also influence the selection between bronze sheets and plates.

Maintenance and Durability of Bronze Sheets and Plates

Bronze sheets offer easier maintenance due to their thinner profile, requiring less effort to clean and polish regularly to prevent oxidation and tarnish. Bronze plates provide superior durability and resistance to wear, making them ideal for high-impact applications where long-term strength is critical. Both bronze sheets and plates benefit from protective coatings or wax treatments that enhance corrosion resistance and prolong lifespan in outdoor or marine environments.

Bronze Sheet vs Bronze Plate Infographic

materialdif.com

materialdif.com