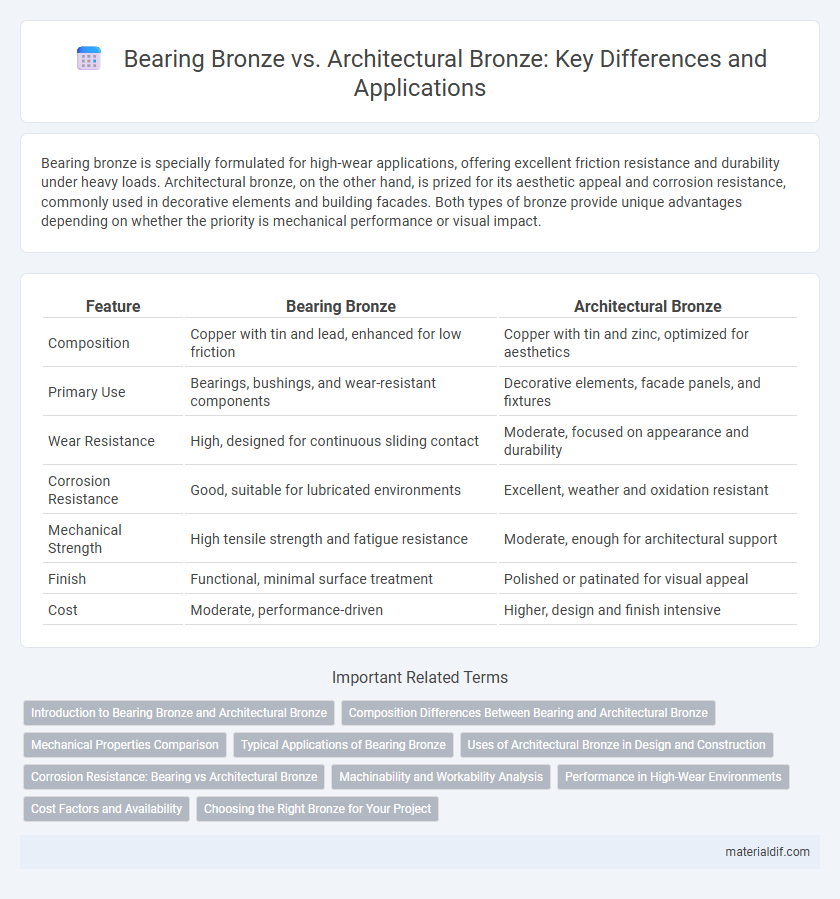

Bearing bronze is specially formulated for high-wear applications, offering excellent friction resistance and durability under heavy loads. Architectural bronze, on the other hand, is prized for its aesthetic appeal and corrosion resistance, commonly used in decorative elements and building facades. Both types of bronze provide unique advantages depending on whether the priority is mechanical performance or visual impact.

Table of Comparison

| Feature | Bearing Bronze | Architectural Bronze |

|---|---|---|

| Composition | Copper with tin and lead, enhanced for low friction | Copper with tin and zinc, optimized for aesthetics |

| Primary Use | Bearings, bushings, and wear-resistant components | Decorative elements, facade panels, and fixtures |

| Wear Resistance | High, designed for continuous sliding contact | Moderate, focused on appearance and durability |

| Corrosion Resistance | Good, suitable for lubricated environments | Excellent, weather and oxidation resistant |

| Mechanical Strength | High tensile strength and fatigue resistance | Moderate, enough for architectural support |

| Finish | Functional, minimal surface treatment | Polished or patinated for visual appeal |

| Cost | Moderate, performance-driven | Higher, design and finish intensive |

Introduction to Bearing Bronze and Architectural Bronze

Bearing bronze is a specialized alloy primarily composed of copper, tin, and lead, designed for high durability and low friction in bearing applications. Architectural bronze, an alloy of copper and tin with a focus on aesthetic appeal and corrosion resistance, is commonly used in building facades, trim, and decorative elements. Both materials leverage bronze's inherent strength and corrosion resistance but serve distinct functional and design purposes in industrial and architectural contexts.

Composition Differences Between Bearing and Architectural Bronze

Bearing bronze primarily consists of copper, tin, and lead, with lead enhancing machinability and wear resistance in high-friction applications. Architectural bronze emphasizes copper and zinc content, often with minimal lead, to improve corrosion resistance and aesthetic appeal for building facades and decorative elements. The distinct alloying elements in bearing bronze optimize durability under mechanical stress, while architectural bronze's composition prioritizes longevity and appearance in outdoor environments.

Mechanical Properties Comparison

Bearing bronze exhibits superior wear resistance and low friction characteristics due to its high tin and lead content, making it ideal for heavy-duty mechanical applications. Architectural bronze offers enhanced tensile strength and corrosion resistance, attributed to higher copper and zinc proportions, ensuring durability in structural and decorative applications. Mechanical properties of bearing bronze prioritize performance under load and movement, whereas architectural bronze emphasizes aesthetic longevity and environmental resilience.

Typical Applications of Bearing Bronze

Bearing bronze is predominantly used in applications requiring high durability and low friction, such as bushings, bearings, and wear plates in heavy machinery and automotive components. Its excellent load-bearing capacity and resistance to wear make it ideal for use in industrial equipment, pumps, and marine hardware. Unlike architectural bronze, which is primarily chosen for aesthetic and corrosion-resistant properties in building facades, bearing bronze focuses on functional performance in mechanical environments.

Uses of Architectural Bronze in Design and Construction

Architectural bronze is prized for its rich color and corrosion resistance, making it ideal for decorative elements such as door frames, window sills, and trim in high-end construction projects. Its durability and aesthetic appeal enhance building facades, interior panels, and custom fixtures, contributing to both form and function in architectural design. Unlike bearing bronze, architectural bronze is chosen primarily for its visual qualities and ability to withstand environmental exposure without sacrificing elegance.

Corrosion Resistance: Bearing vs Architectural Bronze

Bearing bronze exhibits superior corrosion resistance in lubrication-rich environments due to its composition of tin, lead, and copper, which enhances wear resistance and minimizes oxidation. Architectural bronze, primarily an alloy of copper and tin with added zinc or nickel, offers excellent corrosion resistance in atmospheric conditions, maintaining its aesthetic patina over time. Compared to architectural bronze, bearing bronze's corrosion resistance is optimized for mechanical durability, while architectural bronze emphasizes long-term environmental resilience.

Machinability and Workability Analysis

Bearing bronze exhibits superior machinability due to its composition, typically containing tin and lead, which enhances chip formation and reduces tool wear during manufacturing processes. Architectural bronze, often alloyed with aluminum and manganese for improved corrosion resistance and aesthetic appeal, presents moderate machinability but excels in workability, allowing for intricate shaping and finishing in construction applications. The balance between machinability and workability in these bronzes determines their suitability for mechanical components versus decorative architectural elements.

Performance in High-Wear Environments

Bearing bronze exhibits exceptional durability and low friction properties, making it ideal for high-wear environments where continuous movement and heavy loads occur. Architectural bronze offers superior corrosion resistance and aesthetic appeal but may not perform as effectively as bearing bronze under intense physical wear. Selecting bearing bronze ensures enhanced longevity and reliability in mechanical applications subject to constant abrasion and pressure.

Cost Factors and Availability

Bearing bronze is typically more cost-effective due to its widespread production and use in industrial applications, while architectural bronze commands a higher price reflecting its aesthetic qualities and custom finishes. Availability of bearing bronze is generally better, with standard compositions and sizes stocked by most metal suppliers, whereas architectural bronze may require special orders and longer lead times. Both types vary significantly in price based on alloy composition, surface treatment, and demand within their respective markets.

Choosing the Right Bronze for Your Project

Bearing bronze offers superior wear resistance and low friction properties, making it ideal for high-performance mechanical components subjected to continuous motion. Architectural bronze provides excellent corrosion resistance and a visually appealing, warm finish suitable for decorative applications such as building facades and interior design elements. Selecting the right bronze depends on balancing functional requirements--mechanical durability versus aesthetic appeal--to ensure longevity and performance tailored to your project's specific needs.

Bearing Bronze vs Architectural Bronze Infographic

materialdif.com

materialdif.com