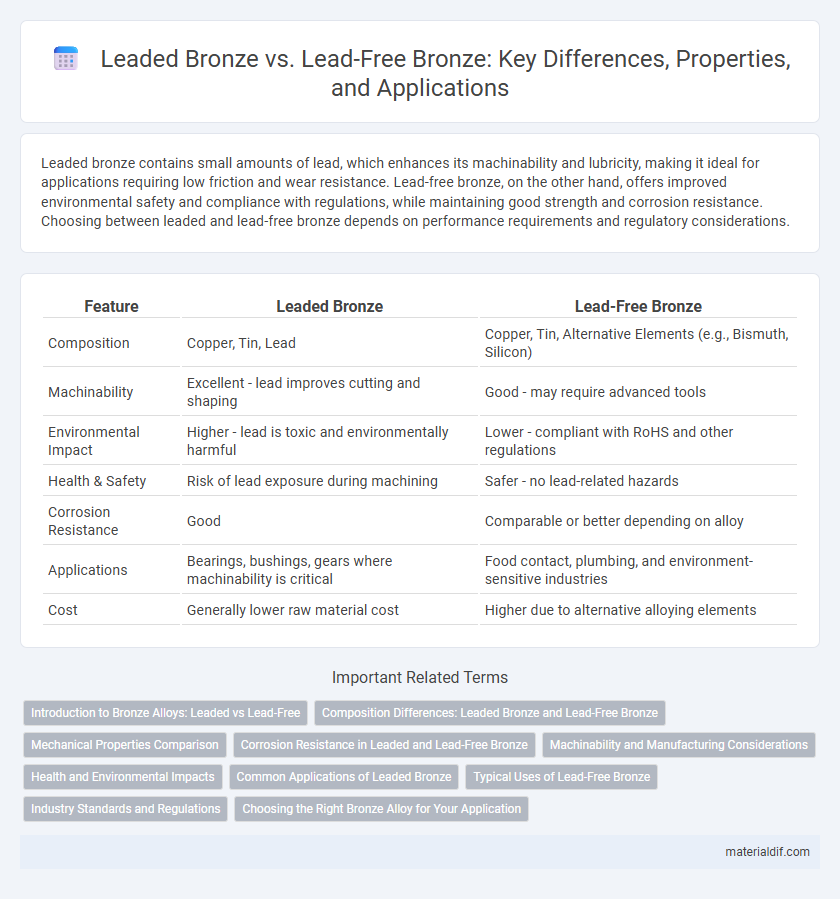

Leaded bronze contains small amounts of lead, which enhances its machinability and lubricity, making it ideal for applications requiring low friction and wear resistance. Lead-free bronze, on the other hand, offers improved environmental safety and compliance with regulations, while maintaining good strength and corrosion resistance. Choosing between leaded and lead-free bronze depends on performance requirements and regulatory considerations.

Table of Comparison

| Feature | Leaded Bronze | Lead-Free Bronze |

|---|---|---|

| Composition | Copper, Tin, Lead | Copper, Tin, Alternative Elements (e.g., Bismuth, Silicon) |

| Machinability | Excellent - lead improves cutting and shaping | Good - may require advanced tools |

| Environmental Impact | Higher - lead is toxic and environmentally harmful | Lower - compliant with RoHS and other regulations |

| Health & Safety | Risk of lead exposure during machining | Safer - no lead-related hazards |

| Corrosion Resistance | Good | Comparable or better depending on alloy |

| Applications | Bearings, bushings, gears where machinability is critical | Food contact, plumbing, and environment-sensitive industries |

| Cost | Generally lower raw material cost | Higher due to alternative alloying elements |

Introduction to Bronze Alloys: Leaded vs Lead-Free

Bronze alloys are primarily composed of copper and tin, with leaded bronze containing small percentages of lead to enhance machinability and lubricity. Lead-free bronze alloys avoid lead due to environmental and health concerns, relying on alternatives like bismuth or tin for improved mechanical properties. Understanding the distinctions between leaded and lead-free bronze is crucial for selecting suitable materials in industrial applications where performance and compliance regulations vary.

Composition Differences: Leaded Bronze and Lead-Free Bronze

Leaded bronze contains a specific percentage of lead, typically ranging from 5% to 11%, which improves machinability and reduces friction in bearing applications. Lead-free bronze replaces lead with alternative elements like tin, aluminum, or phosphorus to enhance environmental compliance and corrosion resistance while maintaining strength. The key compositional difference lies in the presence or absence of lead, directly impacting the alloy's mechanical properties and suitability for various industrial uses.

Mechanical Properties Comparison

Leaded bronze exhibits superior machinability and improved wear resistance due to the presence of lead, making it ideal for components requiring high strength and durability under friction. Lead-free bronze offers enhanced environmental compatibility and better corrosion resistance but generally has lower machinability and slightly reduced tensile strength compared to leaded variants. The mechanical properties balance between leaded and lead-free bronze influences their application in industries where mechanical stress and environmental regulations are critical factors.

Corrosion Resistance in Leaded and Lead-Free Bronze

Leaded bronze offers improved machinability but tends to have lower corrosion resistance compared to lead-free bronze alloys, which are formulated to enhance durability in harsh environments. Lead-free bronze often contains elements like tin, aluminum, or silicon to boost resistance against oxidation and chemical degradation. In marine and industrial applications, lead-free bronze is preferred for its superior performance in resisting pitting, crevice corrosion, and general surface deterioration.

Machinability and Manufacturing Considerations

Leaded bronze offers superior machinability due to the presence of lead, which acts as a lubricant and reduces tool wear, facilitating high-speed machining and producing smoother finishes. Lead-free bronze requires careful selection of machining parameters because its harder matrix can cause increased tool wear and slower cutting speeds, impacting manufacturing efficiency. Manufacturers must weigh the environmental and health benefits of lead-free bronze against the ease of fabrication and operational cost advantages provided by leaded bronze.

Health and Environmental Impacts

Leaded bronze contains lead, which enhances machinability but poses health risks through lead exposure, potentially causing neurological and organ damage. Lead-free bronze eliminates these toxic effects, promoting safer handling and reducing environmental contamination during manufacturing and disposal. Choosing lead-free bronze supports sustainable practices by minimizing hazardous waste and protecting ecosystems from lead pollution.

Common Applications of Leaded Bronze

Leaded bronze is commonly used in bearing applications, marine hardware, and electrical connectors due to its excellent machinability and enhanced wear resistance. Its inherent lead content provides self-lubricating properties, making it ideal for high-friction environments such as bushings, gears, and valve components. Industries like automotive, aerospace, and construction frequently select leaded bronze for components requiring durability and reduced friction.

Typical Uses of Lead-Free Bronze

Lead-free bronze is predominantly used in applications requiring high corrosion resistance and environmental compliance, such as marine hardware, food processing equipment, and plumbing fixtures. Its non-toxic properties make it ideal for potable water systems and components in the pharmaceutical industry. The alloy's durability and machinability support its use in bearings, bushings, and electrical connectors where lead content is restricted.

Industry Standards and Regulations

Leaded bronze is widely used in industrial applications due to its enhanced machinability and conforming to established ASTM standards such as ASTM B505. Lead-free bronze formulations are increasingly adopted to meet stringent environmental regulations like the RoHS directive, which restricts the use of hazardous substances including lead. Compliance with these industry standards ensures that manufacturers can balance performance requirements with regulatory demands across sectors like automotive and marine engineering.

Choosing the Right Bronze Alloy for Your Application

Choosing the right bronze alloy depends heavily on the application's requirements for machinability, corrosion resistance, and strength. Leaded bronze contains small amounts of lead, enhancing machinability and making it ideal for high-precision components like bearings and gears, whereas lead-free bronze offers superior corrosion resistance and environmental safety, preferred in marine and food processing applications. Evaluating the operational environment and regulatory standards ensures the optimal balance between performance and compliance when selecting between leaded and lead-free bronze alloys.

Leaded Bronze vs Lead-Free Bronze Infographic

materialdif.com

materialdif.com