Bell bronze and gunmetal bronze are both copper alloys known for their durability and acoustic properties, but they differ in composition and use. Bell bronze typically contains around 20-22% tin, providing superior resonance and clarity ideal for musical instruments like bells and cymbals. Gunmetal bronze, with a higher tin content of approximately 12-15% and added zinc, offers enhanced corrosion resistance and tensile strength, making it suitable for marine fittings and machinery components.

Table of Comparison

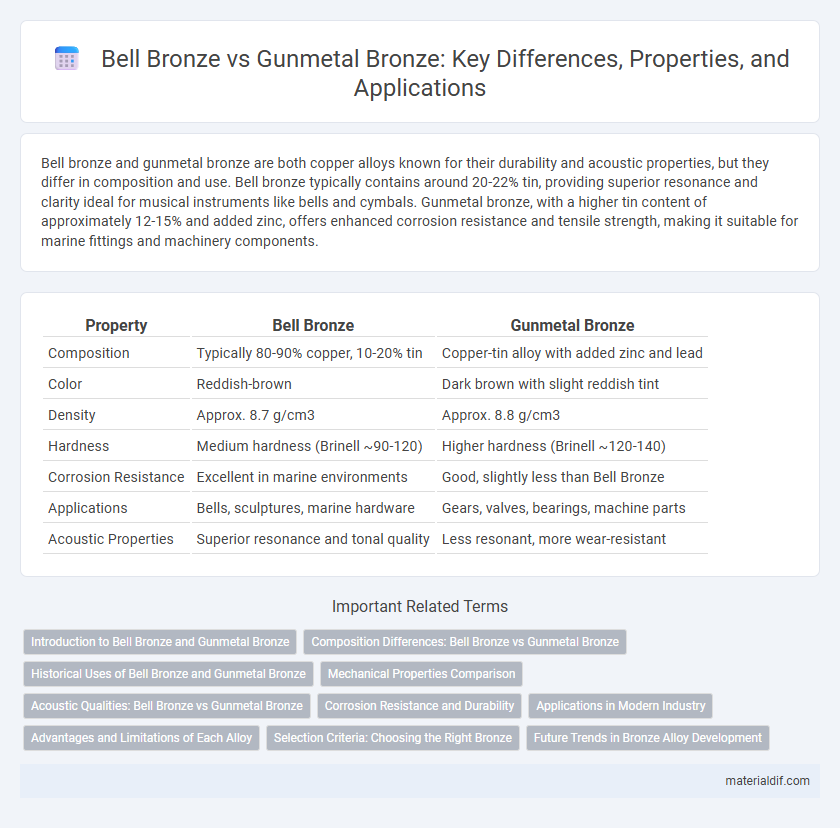

| Property | Bell Bronze | Gunmetal Bronze |

|---|---|---|

| Composition | Typically 80-90% copper, 10-20% tin | Copper-tin alloy with added zinc and lead |

| Color | Reddish-brown | Dark brown with slight reddish tint |

| Density | Approx. 8.7 g/cm3 | Approx. 8.8 g/cm3 |

| Hardness | Medium hardness (Brinell ~90-120) | Higher hardness (Brinell ~120-140) |

| Corrosion Resistance | Excellent in marine environments | Good, slightly less than Bell Bronze |

| Applications | Bells, sculptures, marine hardware | Gears, valves, bearings, machine parts |

| Acoustic Properties | Superior resonance and tonal quality | Less resonant, more wear-resistant |

Introduction to Bell Bronze and Gunmetal Bronze

Bell bronze is a high-tin bronze alloy typically containing about 20-22% tin, prized for its exceptional hardness and resonant sound qualities used predominantly in musical instruments like bells. Gunmetal bronze, generally composed of copper, tin, and zinc, offers superior corrosion resistance and machinability, making it ideal for marine applications and precision hardware. Both alloys exhibit distinct properties tailored to their specific functional demands in acoustic performance and durability.

Composition Differences: Bell Bronze vs Gunmetal Bronze

Bell bronze typically consists of approximately 78% copper and 22% tin, offering high hardness and excellent resonance essential for producing clear, ringing tones in bells. Gunmetal bronze, on the other hand, usually contains about 88% copper, 10% tin, and 2% zinc, providing greater corrosion resistance and machinability suited for bearings, valves, and marine hardware. The increased zinc content in gunmetal bronze differentiates its mechanical properties from bell bronze, optimizing it for applications requiring durability over acoustic performance.

Historical Uses of Bell Bronze and Gunmetal Bronze

Bell bronze, an alloy of approximately 78% copper and 22% tin, has been historically prized for its superior acoustic properties, making it the material of choice for crafting bells and musical instruments since ancient times. Gunmetal bronze, with a composition typically including copper, tin, and zinc, was predominantly used in the manufacturing of cannons, artillery, and marine hardware from the 17th century onward due to its corrosion resistance and strength. These distinctive historical applications reflect the unique mechanical and acoustic qualities that each bronze variant offers in different technological contexts.

Mechanical Properties Comparison

Bell Bronze, an alloy typically composed of approximately 78% copper and 22% tin, exhibits superior tensile strength and hardness compared to Gunmetal Bronze, which generally contains around 88% copper, 10% tin, and 2% zinc. The higher tin content in Bell Bronze enhances its wear resistance and mechanical strength, making it ideal for applications requiring durability and impact resistance, such as bells and bearings. In contrast, Gunmetal Bronze offers better machinability and corrosion resistance due to its zinc content but has lower tensile strength and hardness relative to Bell Bronze.

Acoustic Qualities: Bell Bronze vs Gunmetal Bronze

Bell bronze, composed primarily of copper and tin in an approximate 4:1 ratio, is renowned for its superior acoustic qualities, producing clear, resonant tones with excellent sustain, making it ideal for bells and musical instruments. Gunmetal bronze, typically containing copper, tin, and zinc, offers a slightly denser and harder alloy resulting in a warmer, less bright sound with reduced resonance and sustain compared to bell bronze. The distinct acoustic properties between bell bronze and gunmetal bronze arise from their differing compositions, influencing their vibration characteristics and tonal clarity in sound applications.

Corrosion Resistance and Durability

Bell bronze, an alloy typically composed of around 78% copper and 22% tin, offers superior corrosion resistance ideal for marine and outdoor applications. Gunmetal bronze, consisting mainly of copper, tin, and zinc, provides enhanced durability and strength but exhibits slightly less corrosion resistance compared to bell bronze. The high tin content in bell bronze contributes to its exceptional ability to resist oxidization and maintain structural integrity over time, making it preferable for environments susceptible to moisture and salt exposure.

Applications in Modern Industry

Bell bronze, with its high tin content typically around 20-22%, is favored in applications requiring superior acoustic properties, such as musical instruments and precision bells, due to its excellent resonance and durability. Gunmetal bronze, containing around 5-10% tin and small amounts of zinc, proves more suitable for industrial uses like marine hardware, bearings, and valves, thanks to its enhanced corrosion resistance and tensile strength. Modern industry leverages bell bronze for sound-centric devices, while gunmetal bronze serves in mechanical parts exposed to harsh environments.

Advantages and Limitations of Each Alloy

Bell bronze offers superior acoustic properties and high resistance to metal fatigue, making it ideal for musical instruments like bells and cymbals, while its lower alloying content limits corrosion resistance. Gunmetal bronze exhibits excellent corrosion resistance and strength due to higher tin and copper content, making it suitable for marine applications, but it lacks the tonal quality required for precision sound production. Choosing between the two depends on prioritizing either acoustic performance or environmental durability.

Selection Criteria: Choosing the Right Bronze

Bell Bronze, composed primarily of 78% copper and 22% tin, offers superior resonance and durability, ideal for musical instruments and bells, while Gunmetal Bronze contains roughly 88% copper with tin and zinc, providing better corrosion resistance and machinability suited for marine and industrial applications. Selection criteria hinge on the application's specific requirements for sound quality, mechanical strength, and exposure to environmental factors. Opt for Bell Bronze when acoustic properties and hardness are paramount, whereas Gunmetal Bronze is preferable for wear resistance and performance in corrosive environments.

Future Trends in Bronze Alloy Development

Innovations in Bell Bronze and Gunmetal Bronze alloys center on enhancing durability and acoustic properties through precision metallurgy and nanotechnology. Future trends emphasize eco-friendly production methods and improved corrosion resistance to extend lifecycle performance in marine and industrial applications. Advances in additive manufacturing techniques are expected to revolutionize custom alloy compositions, enabling tailored functionality for specialized uses.

Bell Bronze vs Gunmetal Bronze Infographic

materialdif.com

materialdif.com