Manganese bronze is an alloy primarily composed of copper, zinc, and manganese, known for its high strength, corrosion resistance, and superior machinability, making it ideal for marine and industrial applications. Tin bronze, on the other hand, consists mainly of copper and tin, offering excellent wear resistance, good corrosion resistance, and enhanced hardness, commonly used in bearings, bushings, and decorative objects. Choosing between manganese bronze and tin bronze depends on specific performance requirements such as strength, corrosion resistance, and machining needs.

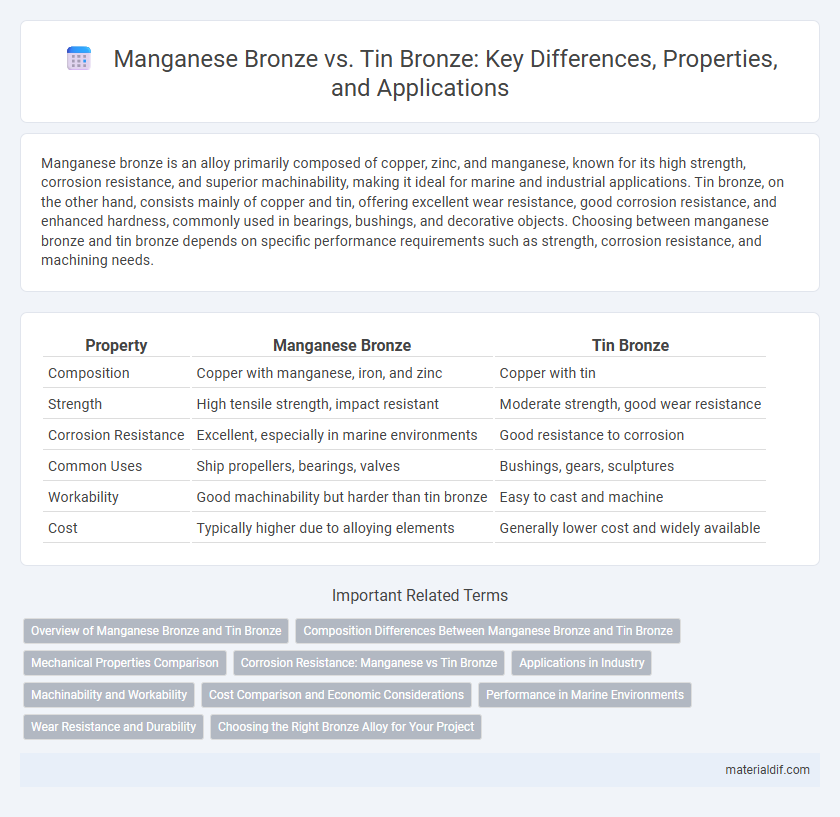

Table of Comparison

| Property | Manganese Bronze | Tin Bronze |

|---|---|---|

| Composition | Copper with manganese, iron, and zinc | Copper with tin |

| Strength | High tensile strength, impact resistant | Moderate strength, good wear resistance |

| Corrosion Resistance | Excellent, especially in marine environments | Good resistance to corrosion |

| Common Uses | Ship propellers, bearings, valves | Bushings, gears, sculptures |

| Workability | Good machinability but harder than tin bronze | Easy to cast and machine |

| Cost | Typically higher due to alloying elements | Generally lower cost and widely available |

Overview of Manganese Bronze and Tin Bronze

Manganese bronze is an alloy primarily composed of copper, zinc, and manganese, known for its high strength, corrosion resistance, and excellent fatigue resistance, making it ideal for marine and heavy-duty applications. Tin bronze, which consists mainly of copper and tin, offers superior corrosion resistance, wear resistance, and machinability, commonly used in bearings, bushings, and springs. Both alloys provide enhanced mechanical properties compared to pure copper, with manganese bronze favored for structural components and tin bronze preferred for applications requiring high wear resistance and corrosion protection.

Composition Differences Between Manganese Bronze and Tin Bronze

Manganese bronze primarily consists of copper, zinc, and manganese, with manganese acting as a key strengthening agent, whereas tin bronze is principally an alloy of copper and tin, with tin enhancing corrosion resistance and hardness. The manganese content in manganese bronze typically ranges from 1.5% to 7%, while tin bronze usually contains 5% to 12% tin, influencing their mechanical and chemical properties significantly. These composition differences result in manganese bronze having higher tensile strength and wear resistance compared to the more corrosion-resistant and ductile tin bronze.

Mechanical Properties Comparison

Manganese bronze exhibits higher tensile strength and improved fatigue resistance compared to tin bronze, making it ideal for heavy-duty applications requiring durability. Tin bronze offers superior corrosion resistance and better wear properties, favored for marine and bearing components. The choice between the two depends on balancing mechanical strength with environmental resistance needs.

Corrosion Resistance: Manganese vs Tin Bronze

Manganese bronze exhibits superior corrosion resistance in marine environments due to its high manganese content, which enhances its ability to withstand saltwater exposure and oxidation. Tin bronze, while also corrosion-resistant, performs better in freshwater settings because tin improves its resistance to general corrosion but is less effective against chloride-induced degradation. Manganese bronze's durability against pitting and crevice corrosion makes it a preferred choice for ship propellers and underwater components.

Applications in Industry

Manganese bronze, known for its high tensile strength and excellent corrosion resistance, is widely used in marine applications, heavy-duty gears, and valve components where durability under harsh conditions is critical. Tin bronze offers superior wear resistance and low friction, making it a preferred choice for bearings, bushings, and electrical connectors in automotive and electrical industries. Both alloys find niche applications based on their respective mechanical properties, optimizing performance in specialized industrial environments.

Machinability and Workability

Manganese bronze offers superior machinability compared to tin bronze due to its higher strength and toughness, making it ideal for precision engineering applications requiring complex shapes and tight tolerances. Tin bronze exhibits excellent workability and corrosion resistance but tends to be less machinable, often necessitating slower cutting speeds and specialized tooling. Selecting between manganese bronze and tin bronze depends on the balance between machining efficiency and the required mechanical properties for the final product.

Cost Comparison and Economic Considerations

Manganese bronze generally costs more than tin bronze due to its complex alloy composition, which includes higher percentages of manganese, copper, and zinc, increasing manufacturing expenses. Tin bronze offers a more economical solution with lower raw material costs and simpler production processes, making it favorable for large-scale applications where budget constraints are critical. Economic considerations often drive industries like marine and automotive to choose tin bronze for its cost-efficiency without significantly compromising durability and corrosion resistance.

Performance in Marine Environments

Manganese bronze exhibits superior corrosion resistance and tensile strength compared to tin bronze, making it more suitable for marine environments with high salinity and mechanical stress. Its enhanced wear resistance and ability to withstand cavitation erosion contribute to longer-lasting performance in ship propellers and underwater fittings. Tin bronze offers good corrosion resistance but generally falls short in strength and durability under harsh marine conditions.

Wear Resistance and Durability

Manganese bronze exhibits superior wear resistance compared to tin bronze due to its higher tensile strength and toughness, making it ideal for applications involving heavy mechanical stress. Its composition, rich in manganese, copper, and zinc, enhances durability and corrosion resistance, outperforming tin bronze in harsh environments. Tin bronze, while excellent for ease of casting and corrosion resistance, generally offers less wear resistance and lower durability under continuous friction or load-bearing conditions.

Choosing the Right Bronze Alloy for Your Project

Manganese bronze offers superior strength and corrosion resistance, making it ideal for heavy-duty marine and industrial applications, while tin bronze provides excellent wear resistance and machinability suited for bearings and bushings. Selecting the right bronze alloy depends on specific project requirements such as mechanical strength, environmental exposure, and machining complexity. Understanding the distinct properties of manganese bronze and tin bronze ensures optimal performance and durability in your final product.

Manganese Bronze vs Tin Bronze Infographic

materialdif.com

materialdif.com