Gunmetal bronze is an alloy composed primarily of copper, tin, and zinc, known for its dark blue-gray appearance, high machinability, and excellent corrosion resistance, making it ideal for marine fittings and bearings. Manganese bronze, containing copper, zinc, and manganese, offers superior tensile strength and wear resistance, often used in heavy-duty applications like ship propellers and industrial valves. Both alloys possess strong durability, but gunmetal bronze excels in environments requiring corrosion resistance, while manganese bronze is favored for strength and toughness.

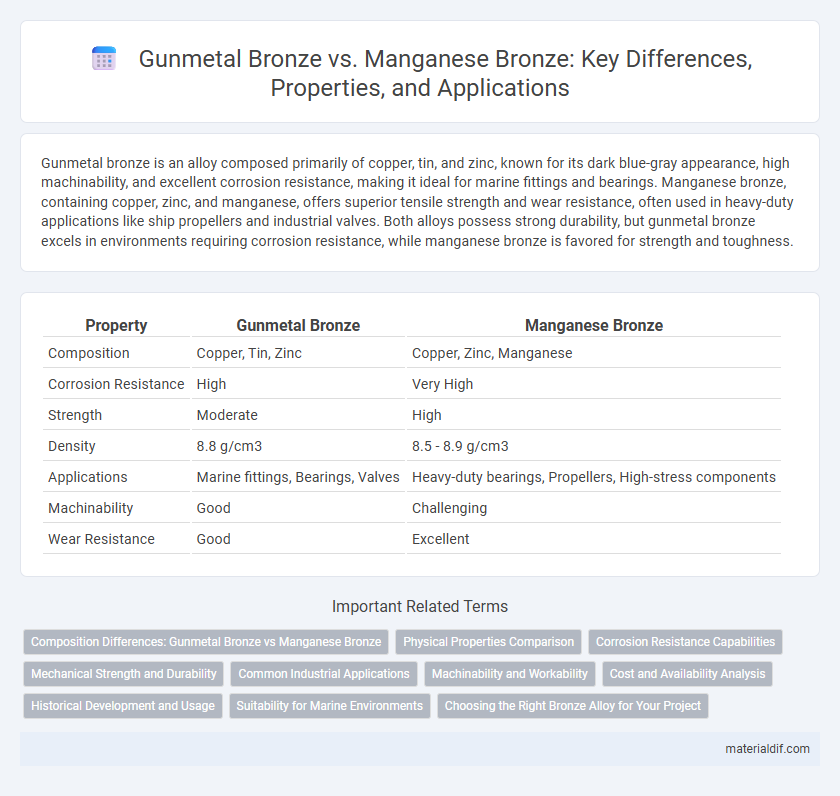

Table of Comparison

| Property | Gunmetal Bronze | Manganese Bronze |

|---|---|---|

| Composition | Copper, Tin, Zinc | Copper, Zinc, Manganese |

| Corrosion Resistance | High | Very High |

| Strength | Moderate | High |

| Density | 8.8 g/cm3 | 8.5 - 8.9 g/cm3 |

| Applications | Marine fittings, Bearings, Valves | Heavy-duty bearings, Propellers, High-stress components |

| Machinability | Good | Challenging |

| Wear Resistance | Good | Excellent |

Composition Differences: Gunmetal Bronze vs Manganese Bronze

Gunmetal bronze primarily consists of copper, tin, and zinc with small amounts of lead to improve machinability, while manganese bronze contains copper, zinc, and manganese along with small percentages of iron, aluminum, and nickel to enhance strength. The higher manganese and additional alloying elements in manganese bronze contribute to superior tensile strength and corrosion resistance compared to the more traditional tin-based gunmetal bronze. The distinct composition variations directly influence their mechanical properties and suitability for applications requiring durability and wear resistance.

Physical Properties Comparison

Gunmetal bronze exhibits high corrosion resistance and good tensile strength, making it ideal for marine applications. Manganese bronze offers superior impact toughness and greater hardness, enhancing its durability in heavy-load environments. Both alloys possess excellent wear resistance, but manganese bronze typically outperforms gunmetal in terms of strength and machinability.

Corrosion Resistance Capabilities

Gunmetal bronze exhibits moderate corrosion resistance, particularly effective against seawater and atmospheric exposure due to its high copper and tin content. Manganese bronze offers superior corrosion resistance in marine environments, enhanced by manganese's ability to improve strength and wear resistance even under harsh conditions. Both alloys resist corrosion well, but manganese bronze is preferred for applications requiring higher durability and long-term performance in saltwater settings.

Mechanical Strength and Durability

Gunmetal bronze, an alloy primarily composed of copper, tin, and zinc, is known for its moderate mechanical strength and excellent corrosion resistance, making it suitable for marine applications. Manganese bronze, which contains copper, zinc, and significant manganese content, exhibits higher tensile strength and superior durability, ideal for heavy-duty machinery and load-bearing components. The enhanced mechanical strength of manganese bronze results from its manganese content, providing better wear resistance and fatigue strength compared to gunmetal bronze.

Common Industrial Applications

Gunmetal bronze, known for its corrosion resistance and machinability, is widely used in marine hardware, valves, and bearings where durability against saltwater is critical. Manganese bronze, with superior strength and wear resistance, finds common industrial applications in heavy-duty gears, pumps, and ship propellers requiring enhanced mechanical performance. Both alloys are essential in manufacturing robust components exposed to harsh mechanical stress and corrosive environments.

Machinability and Workability

Gunmetal bronze exhibits superior machinability due to its balanced composition of copper, tin, and zinc, allowing for precise cutting and shaping with minimal tool wear. Manganese bronze, containing higher manganese and iron content, offers greater strength and durability but presents challenges in workability, often requiring specialized machining techniques to avoid material fatigue. Both alloys serve distinct industrial applications where machinability and workability requirements vary, with gunmetal preferred for intricate, detailed parts and manganese bronze favored for heavy-duty components.

Cost and Availability Analysis

Gunmetal bronze generally offers lower cost and wider availability than manganese bronze, making it a more budget-friendly option for many industrial applications. Manganese bronze, while more expensive due to the inclusion of manganese and higher strength properties, tends to have limited availability primarily in specialized markets. The cost difference is influenced by the raw material sourcing and manufacturing processes, with gunmetal bronze benefiting from a more established supply chain.

Historical Development and Usage

Gunmetal bronze, historically developed in the 17th century, is an alloy consisting primarily of copper, tin, and zinc, prized for its corrosion resistance and use in naval applications such as cannons and ship fittings. Manganese bronze emerged in the 19th century, incorporating manganese and additional elements to enhance strength and wear resistance, commonly employed in heavy-duty industrial components and marine propellers. The distinct metallurgical advancements in each alloy reflect their specialized roles in technology and manufacturing throughout history.

Suitability for Marine Environments

Gunmetal bronze offers superior corrosion resistance and excellent strength, making it highly suitable for marine environments with prolonged exposure to saltwater. Manganese bronze, while strong and wear-resistant, tends to be less corrosion-resistant in aggressive seawater conditions without protective coatings. Both alloys are used in shipbuilding and underwater fittings, but gunmetal bronze is preferred for applications requiring long-term durability against saltwater corrosion.

Choosing the Right Bronze Alloy for Your Project

Gunmetal bronze, an alloy of copper, tin, and zinc, offers high corrosion resistance and excellent machinability, making it ideal for precision components and marine applications. Manganese bronze, composed primarily of copper, zinc, and manganese, provides superior tensile strength and wear resistance, suited for heavy-load structures and industrial machinery. Selecting between gunmetal and manganese bronze depends on project requirements for durability, strength, and environmental exposure.

Gunmetal Bronze vs Manganese Bronze Infographic

materialdif.com

materialdif.com