Marine bronze offers superior corrosion resistance and durability in saltwater environments due to its higher copper and tin content combined with small amounts of nickel and iron, making it ideal for ship fittings and underwater components. Bearing bronze, on the other hand, is specifically alloyed with elements like lead for enhanced machinability and low friction, providing excellent wear resistance for bushings, bearings, and heavy-load applications. Choosing between marine bronze and bearing bronze depends on the environment and mechanical requirements, with marine bronze excelling in corrosive conditions and bearing bronze optimized for friction reduction and load handling.

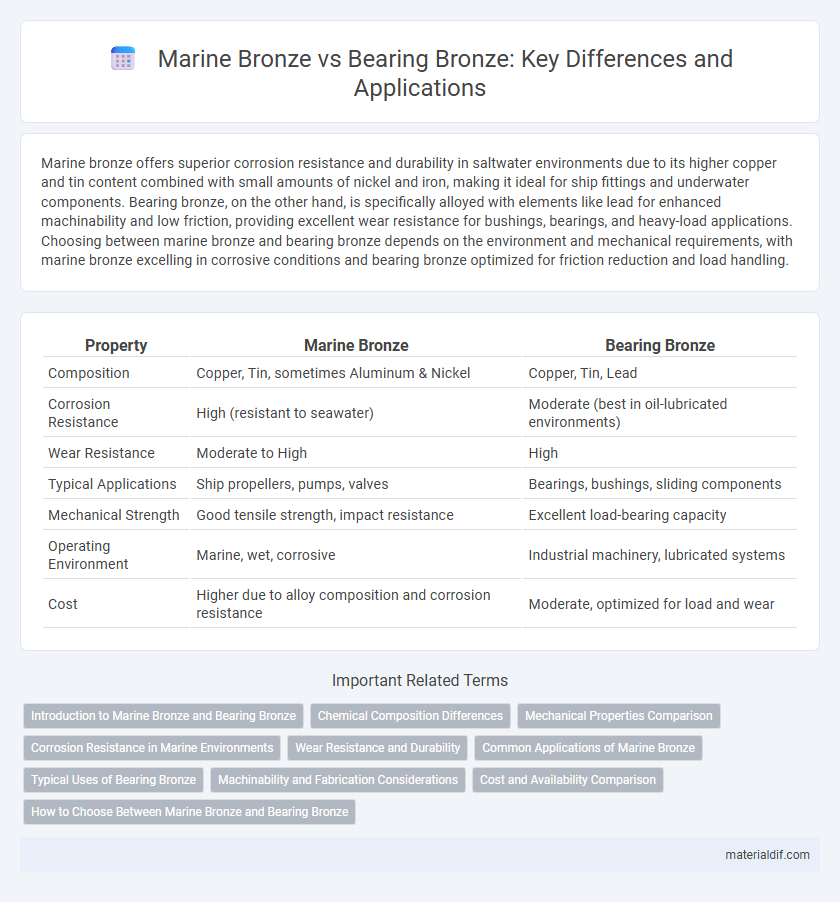

Table of Comparison

| Property | Marine Bronze | Bearing Bronze |

|---|---|---|

| Composition | Copper, Tin, sometimes Aluminum & Nickel | Copper, Tin, Lead |

| Corrosion Resistance | High (resistant to seawater) | Moderate (best in oil-lubricated environments) |

| Wear Resistance | Moderate to High | High |

| Typical Applications | Ship propellers, pumps, valves | Bearings, bushings, sliding components |

| Mechanical Strength | Good tensile strength, impact resistance | Excellent load-bearing capacity |

| Operating Environment | Marine, wet, corrosive | Industrial machinery, lubricated systems |

| Cost | Higher due to alloy composition and corrosion resistance | Moderate, optimized for load and wear |

Introduction to Marine Bronze and Bearing Bronze

Marine bronze, an alloy primarily composed of copper, tin, and sometimes zinc, offers exceptional resistance to seawater corrosion, making it ideal for shipbuilding, propellers, and underwater components. Bearing bronze, typically a copper alloy with added lead or tin, is engineered for durability and low friction in bearing and bushing applications, ensuring efficient mechanical performance. Both alloys leverage the inherent strength of bronze but are optimized for distinct environments--marine conditions versus mechanical wear.

Chemical Composition Differences

Marine bronze typically contains higher levels of copper and tin, with added elements such as zinc and lead to enhance corrosion resistance in seawater environments. Bearing bronze, conversely, has increased amounts of lead and tin to improve its lubricating properties and wear resistance under friction. The distinct chemical compositions of marine bronze and bearing bronze tailor their performance characteristics for specific applications in marine and mechanical settings.

Mechanical Properties Comparison

Marine bronze exhibits excellent corrosion resistance and good strength, making it ideal for harsh saltwater environments where durability and resistance to marine corrosion are critical. Bearing bronze, formulated with high tin content and lubricating elements like lead or graphite, offers superior wear resistance and high load-bearing capacity, which ensures longer service life in friction-intensive applications. Mechanical properties emphasize that marine bronze typically has moderate tensile strength around 55,000 psi and elongation near 20%, whereas bearing bronze can achieve higher tensile strength exceeding 70,000 psi and enhanced hardness for improved mechanical performance under heavy loads.

Corrosion Resistance in Marine Environments

Marine bronze offers superior corrosion resistance in saltwater environments due to its high copper and tin content combined with small amounts of nickel and aluminum, which enhance its durability against seawater corrosion. Bearing bronze, typically composed of copper, tin, and lead, is optimized for wear resistance and load-bearing applications but may not perform as well in marine conditions because its alloying elements provide less protection against saltwater-induced corrosion. Selecting marine bronze ensures longer lifespan and reduced maintenance in harsh marine environments compared to bearing bronze.

Wear Resistance and Durability

Marine bronze exhibits superior corrosion resistance in saltwater environments, making it highly durable for marine applications. Bearing bronze offers enhanced wear resistance due to its optimized alloy composition, ensuring prolonged service life under heavy load and friction. When selecting bronze for marine machinery, marine bronze ensures longevity against seawater damage, while bearing bronze excels in reducing wear and friction in moving parts.

Common Applications of Marine Bronze

Marine bronze, a copper alloy with high corrosion resistance and strength, is primarily used in boat propellers, ship fittings, and underwater fasteners due to its excellent performance in seawater environments. Its applications extend to pump and valve components in marine systems, where durability and resistance to biofouling are critical. Bearing bronze, while ideal for bearing and bushing applications because of its low friction and wear properties, is less suited for direct exposure to harsh marine conditions compared to marine bronze.

Typical Uses of Bearing Bronze

Bearing bronze is primarily used in applications requiring high wear resistance and low friction, such as bushings, bearings, and wear plates in heavy machinery and automotive components. Its composition typically includes tin and lead, which enhance its anti-friction properties and durability under high load conditions. Bearing bronze's ability to withstand heavy loads and resist corrosion makes it ideal for marine equipment, pumps, and industrial gear systems.

Machinability and Fabrication Considerations

Marine bronze offers superior corrosion resistance in saltwater environments, making it ideal for nautical applications, while bearing bronze excels in wear resistance and fatigue strength for heavy load-bearing components. Machinability of bearing bronze is generally better due to its uniform microstructure and alloy composition, facilitating precision fabrication and tighter tolerances. Fabrication of marine bronze often requires careful control of heat treatment processes to preserve its anti-corrosive properties and mechanical integrity under marine conditions.

Cost and Availability Comparison

Marine bronze, typically composed of copper, tin, and small amounts of nickel and iron, is more expensive than bearing bronze due to its superior corrosion resistance and strength in saltwater environments. Bearing bronze, mainly an alloy of copper, tin, and lead, is generally more affordable and widely available because it is designed for industrial applications with less demanding corrosion requirements. Availability of marine bronze can be limited by specific alloy composition and demand in maritime industries, while bearing bronze benefits from broader industrial use and easier sourcing.

How to Choose Between Marine Bronze and Bearing Bronze

Choosing between marine bronze and bearing bronze depends on the specific application requirements such as corrosion resistance, load-bearing capacity, and environmental conditions. Marine bronze offers superior resistance to saltwater corrosion, making it ideal for shipbuilding and underwater fittings, whereas bearing bronze excels in wear resistance and is suited for high-load, low-speed bearing applications. Evaluate factors including exposure to seawater, mechanical stress, and friction to determine the most effective material for durability and performance.

Marine Bronze vs Bearing Bronze Infographic

materialdif.com

materialdif.com