Oil-impregnated bronze offers enhanced self-lubrication properties, reducing friction and wear in machinery without the need for external lubricants. Solid bronze, while durable and corrosion-resistant, typically requires regular lubrication to maintain optimal performance. The choice between oil-impregnated and solid bronze depends on the application's lubrication needs and maintenance preferences.

Table of Comparison

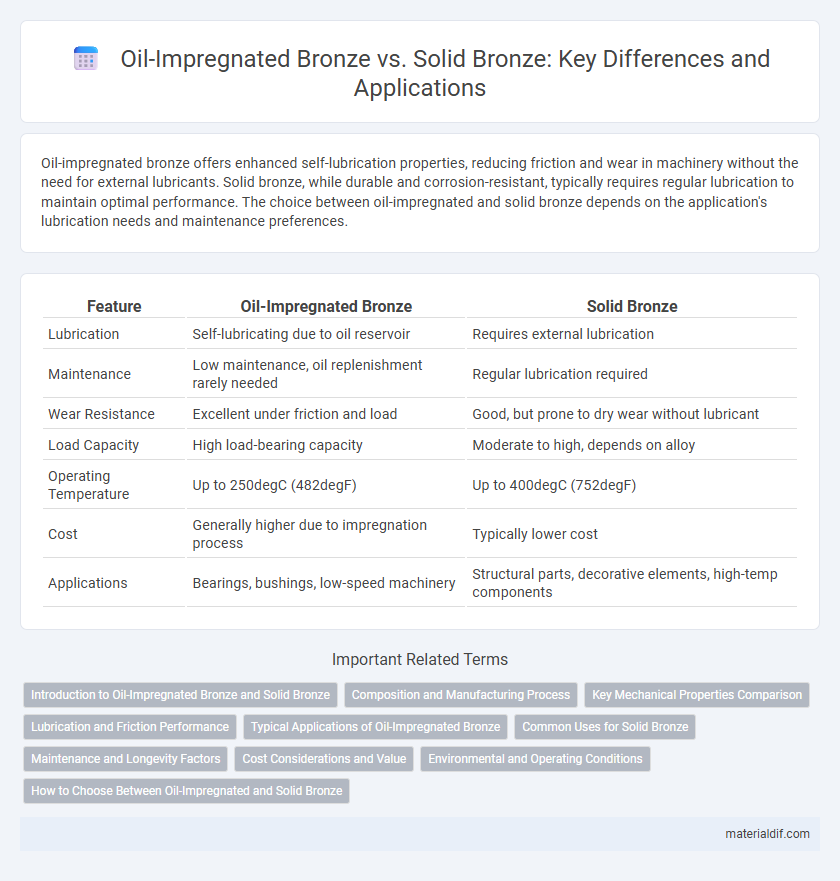

| Feature | Oil-Impregnated Bronze | Solid Bronze |

|---|---|---|

| Lubrication | Self-lubricating due to oil reservoir | Requires external lubrication |

| Maintenance | Low maintenance, oil replenishment rarely needed | Regular lubrication required |

| Wear Resistance | Excellent under friction and load | Good, but prone to dry wear without lubricant |

| Load Capacity | High load-bearing capacity | Moderate to high, depends on alloy |

| Operating Temperature | Up to 250degC (482degF) | Up to 400degC (752degF) |

| Cost | Generally higher due to impregnation process | Typically lower cost |

| Applications | Bearings, bushings, low-speed machinery | Structural parts, decorative elements, high-temp components |

Introduction to Oil-Impregnated Bronze and Solid Bronze

Oil-impregnated bronze is a porous bronze material infused with lubricating oil, providing self-lubricating properties that reduce friction and wear in applications with limited maintenance access. Solid bronze, composed of a dense alloy of copper and tin, offers high strength and excellent corrosion resistance but requires external lubrication to prevent friction and wear. The choice between oil-impregnated and solid bronze hinges on maintenance needs, load conditions, and operating environments.

Composition and Manufacturing Process

Oil-impregnated bronze consists of a porous bronze matrix infused with lubricant oil, enhancing its self-lubricating properties and reducing friction in dynamic applications. In contrast, solid bronze is a dense, homogeneous alloy primarily composed of copper and tin, manufactured through casting or forging without incorporating internal lubrication. The oil-impregnated bronze undergoes a sintering process to create its porous structure, whereas solid bronze relies on traditional metallurgical techniques for shaping and finishing.

Key Mechanical Properties Comparison

Oil-impregnated bronze exhibits superior self-lubricating properties, reducing friction and wear compared to solid bronze, making it ideal for high-load and low-speed applications. Solid bronze offers higher tensile strength and better corrosion resistance, which suits structural components exposed to harsh environments. The porous nature of oil-impregnated bronze lowers its density and hardness, enhancing shock absorption but limiting its load-bearing capacity relative to solid bronze.

Lubrication and Friction Performance

Oil-impregnated bronze offers superior lubrication performance as it contains embedded oil reservoirs that continuously release lubricant, reducing friction and wear without the need for external lubrication. Solid bronze, lacking internal lubrication, typically requires regular application of external lubricants to maintain low friction levels and prevent surface damage. The self-lubricating nature of oil-impregnated bronze enhances durability and efficiency in high-load, high-speed applications compared to traditional solid bronze components.

Typical Applications of Oil-Impregnated Bronze

Oil-impregnated bronze is predominantly used in applications requiring self-lubricating properties such as bearing surfaces in electric motors, pumps, and automotive components. Its porous structure, impregnated with oil, reduces friction and wear in environments with limited maintenance access. Typical applications include bushings, sleeve bearings, and valve guides where continuous lubrication ensures performance and longevity.

Common Uses for Solid Bronze

Solid bronze is commonly used in applications requiring high strength and wear resistance, such as marine hardware, musical instruments, and sculptures. Its excellent corrosion resistance makes it ideal for outdoor and underwater environments. Solid bronze is also favored for bearing components where durability and load-bearing capacity are critical.

Maintenance and Longevity Factors

Oil-impregnated bronze offers self-lubrication, significantly reducing maintenance requirements and extending service life in high-wear applications. Solid bronze, while durable, demands regular external lubrication to prevent friction and wear, increasing downtime and maintenance costs. The inherent lubrication feature of oil-impregnated bronze enhances longevity, making it ideal for applications where consistent performance and minimal maintenance are critical.

Cost Considerations and Value

Oil-impregnated bronze offers significant cost savings compared to solid bronze by reducing the need for external lubrication and maintenance, thereby lowering long-term operational expenses. The initial investment in oil-impregnated bronze may be higher, but its self-lubricating properties extend bearing life and minimize downtime, enhancing overall value. Solid bronze, while generally cheaper upfront, often incurs higher maintenance costs and more frequent replacements, impacting total cost of ownership negatively.

Environmental and Operating Conditions

Oil-impregnated bronze excels in harsh environmental and operating conditions by providing continuous lubrication, which reduces friction, wear, and the risk of corrosion in low-speed, high-load applications. Solid bronze, while durable and resistant to corrosion, requires external lubrication and is better suited for higher-speed operations with less contamination risk. Choosing the appropriate bronze type depends on factors such as load, speed, temperature, and exposure to moisture or chemicals, with oil-impregnated bronze offering enhanced performance in demanding, maintenance-restricted environments.

How to Choose Between Oil-Impregnated and Solid Bronze

Choosing between oil-impregnated bronze and solid bronze depends on the application's friction, lubrication, and maintenance requirements. Oil-impregnated bronze self-lubricates, ideal for low-maintenance environments requiring reduced wear in bearings and bushings. Solid bronze offers higher strength and corrosion resistance, suited for heavy-load conditions where external lubrication is feasible.

Oil-Impregnated Bronze vs Solid Bronze Infographic

materialdif.com

materialdif.com