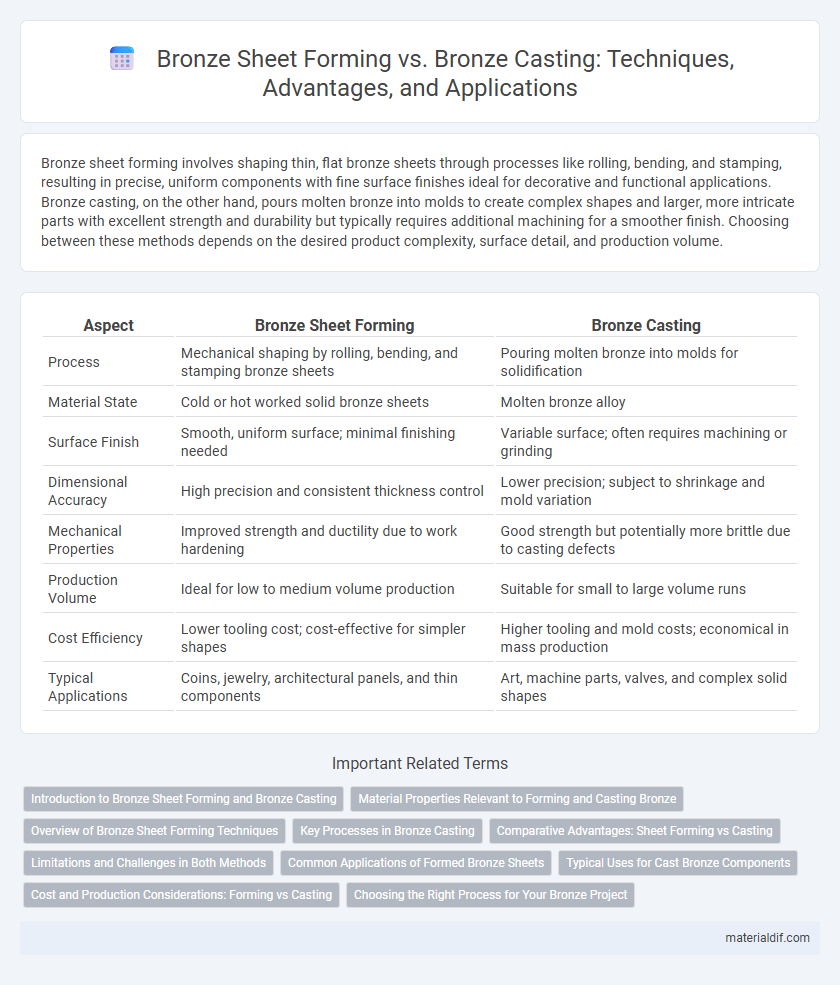

Bronze sheet forming involves shaping thin, flat bronze sheets through processes like rolling, bending, and stamping, resulting in precise, uniform components with fine surface finishes ideal for decorative and functional applications. Bronze casting, on the other hand, pours molten bronze into molds to create complex shapes and larger, more intricate parts with excellent strength and durability but typically requires additional machining for a smoother finish. Choosing between these methods depends on the desired product complexity, surface detail, and production volume.

Table of Comparison

| Aspect | Bronze Sheet Forming | Bronze Casting |

|---|---|---|

| Process | Mechanical shaping by rolling, bending, and stamping bronze sheets | Pouring molten bronze into molds for solidification |

| Material State | Cold or hot worked solid bronze sheets | Molten bronze alloy |

| Surface Finish | Smooth, uniform surface; minimal finishing needed | Variable surface; often requires machining or grinding |

| Dimensional Accuracy | High precision and consistent thickness control | Lower precision; subject to shrinkage and mold variation |

| Mechanical Properties | Improved strength and ductility due to work hardening | Good strength but potentially more brittle due to casting defects |

| Production Volume | Ideal for low to medium volume production | Suitable for small to large volume runs |

| Cost Efficiency | Lower tooling cost; cost-effective for simpler shapes | Higher tooling and mold costs; economical in mass production |

| Typical Applications | Coins, jewelry, architectural panels, and thin components | Art, machine parts, valves, and complex solid shapes |

Introduction to Bronze Sheet Forming and Bronze Casting

Bronze sheet forming involves shaping thin metal sheets through processes like rolling, bending, and stamping, offering precise thickness control and smooth surface finishes ideal for decorative and functional applications. Bronze casting, by contrast, creates complex shapes by pouring molten bronze into molds, allowing for intricate details and robust structural components in art, machinery, and tools. Both techniques utilize bronze's excellent corrosion resistance and tensile strength, but sheet forming excels in uniformity and surface quality while casting prioritizes design complexity and volume production.

Material Properties Relevant to Forming and Casting Bronze

Bronze sheet forming benefits from the alloy's excellent ductility, allowing complex shapes to be created through processes like rolling and stamping without cracking. In casting, bronze's superior fluidity and low melting point enable precise mold filling and detailed reproductions, though brittleness increases with higher tin content. Material properties such as tensile strength, hardness, and thermal conductivity critically influence the choice between forming and casting methods to optimize final component performance.

Overview of Bronze Sheet Forming Techniques

Bronze sheet forming encompasses techniques such as rolling, hammering, and deep drawing, which refine the metal's thickness and shape while enhancing its mechanical properties. This process allows precise control over dimensions and surface finish, making it ideal for applications requiring uniform thickness and intricate designs. Compared to bronze casting, sheet forming offers improved material strength and ductility due to work hardening during deformation.

Key Processes in Bronze Casting

Bronze casting involves pouring molten bronze into molds where it solidifies into complex shapes with precise details, allowing for intricate designs unattainable through sheet forming. Key processes in bronze casting include pattern creation, mold making, metal melting, pouring, cooling, and finishing, each essential for achieving durability and fine surface quality. Unlike bronze sheet forming, which reshapes pre-existing sheets through mechanical means like rolling or hammering, casting provides greater design freedom and structural integrity in producing complex bronze components.

Comparative Advantages: Sheet Forming vs Casting

Bronze sheet forming offers enhanced dimensional accuracy and surface finish compared to casting, making it ideal for applications requiring tight tolerances and smooth surfaces. Sheet forming provides better mechanical properties due to work hardening, resulting in improved strength and durability over cast components. Casting, however, allows for more complex and intricate shapes, but generally struggles with porosity and surface imperfections that are less prevalent in formed sheets.

Limitations and Challenges in Both Methods

Bronze sheet forming faces limitations such as restricted thickness reduction and increased risk of cracking due to the alloy's lower ductility, making complex shapes challenging to achieve. Bronze casting, while allowing for intricate designs, often encounters issues with porosity, shrinkage, and dimensional inaccuracies that can affect structural integrity. Both methods require careful control of temperature and composition to mitigate defects and ensure the desired mechanical properties in the final bronze components.

Common Applications of Formed Bronze Sheets

Formed bronze sheets are widely utilized in architectural components, decorative panels, and precision electrical connectors due to their excellent malleability and corrosion resistance. Unlike bronze casting, which creates complex shapes for heavy-duty machinery parts and sculptures, sheet forming enables thin, uniform layers ideal for heat exchangers and musical instruments. These applications benefit from the controlled thickness and surface finish achieved through rolling and pressing processes.

Typical Uses for Cast Bronze Components

Cast bronze components are predominantly used in applications requiring complex shapes and superior corrosion resistance, such as marine hardware, sculptures, and bearing housings. The casting process allows for the production of large, intricate parts that are difficult to achieve through sheet forming. Industries like aerospace, automotive, and art frequently utilize cast bronze for its durability and versatility in demanding environments.

Cost and Production Considerations: Forming vs Casting

Bronze sheet forming generally incurs higher initial tooling costs but offers faster production cycles and greater material efficiency for large quantities, resulting in lower per-unit costs. Bronze casting involves lower upfront expenses with flexible design capabilities but demands longer lead times and may cause higher material waste, increasing overall costs. Selecting between bronze sheet forming and casting depends on production volume, design complexity, and cost-efficiency priorities.

Choosing the Right Process for Your Bronze Project

Selecting the appropriate bronze manufacturing method depends on project specifications such as thickness, detail, and durability requirements. Bronze sheet forming excels in creating thin, precise components with superior surface finish and work-hardening properties, ideal for decorative or structural elements. Bronze casting, however, provides greater versatility for complex shapes and large, heavy parts, offering excellent strength and dimensional accuracy in industrial or artistic applications.

Bronze Sheet Forming vs Bronze Casting Infographic

materialdif.com

materialdif.com