Coinage bronze is a high-quality alloy typically composed of about 88% copper and 12% tin, valued for its durability and resistance to corrosion, making it ideal for minting coins. Industrial bronze contains a more varied composition, often including additional elements like aluminum, manganese, or nickel to enhance strength, wear resistance, and machinability for heavy-duty applications. The distinct formulations optimize each type for its specific use, with coinage bronze prioritizing longevity and detail retention, while industrial bronze emphasizes mechanical properties and functionality.

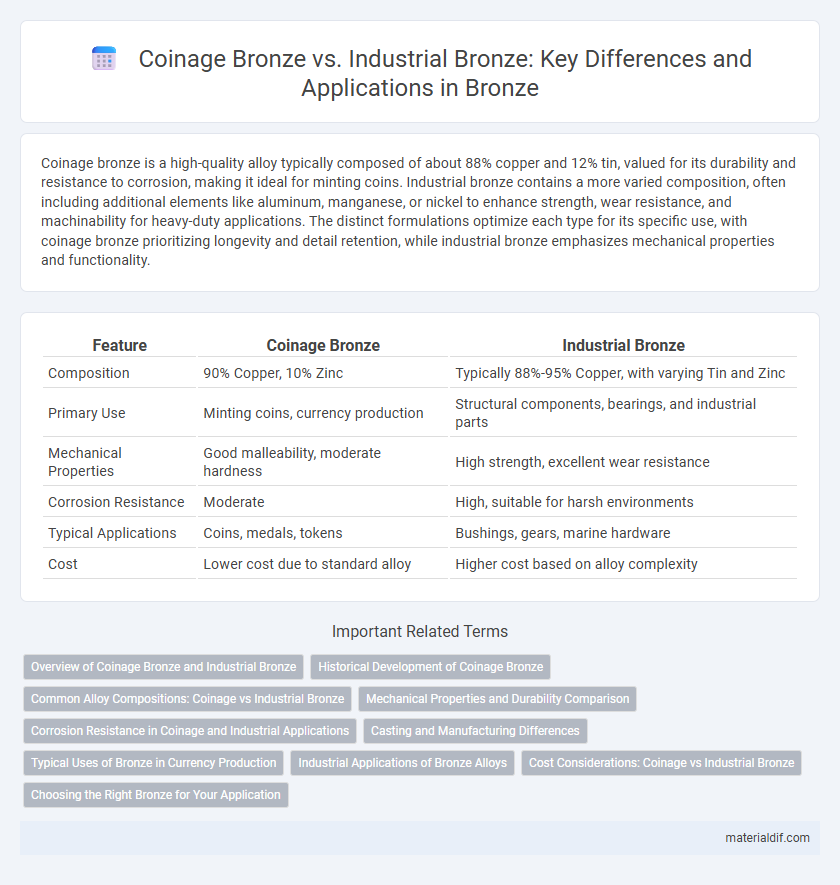

Table of Comparison

| Feature | Coinage Bronze | Industrial Bronze |

|---|---|---|

| Composition | 90% Copper, 10% Zinc | Typically 88%-95% Copper, with varying Tin and Zinc |

| Primary Use | Minting coins, currency production | Structural components, bearings, and industrial parts |

| Mechanical Properties | Good malleability, moderate hardness | High strength, excellent wear resistance |

| Corrosion Resistance | Moderate | High, suitable for harsh environments |

| Typical Applications | Coins, medals, tokens | Bushings, gears, marine hardware |

| Cost | Lower cost due to standard alloy | Higher cost based on alloy complexity |

Overview of Coinage Bronze and Industrial Bronze

Coinage bronze, primarily composed of copper, tin, and a small percentage of zinc, is tailored for minting coins due to its durability, corrosion resistance, and attractive finish. Industrial bronze, often containing higher concentrations of tin and sometimes other alloying elements like aluminum or manganese, is engineered for strength and wear resistance in heavy-duty applications such as bearings, bushings, and marine hardware. Both types of bronze exhibit excellent machinability and thermal conductivity but differ significantly in composition to meet their specific functional requirements.

Historical Development of Coinage Bronze

Coinage bronze, historically alloyed with approximately 88% copper and 12% tin, emerged during the Bronze Age to provide durable and corrosion-resistant materials for minting coins. Unlike industrial bronze, which varies widely in composition for specialized mechanical and structural applications, coinage bronze maintained consistent standards to ensure uniform weight and wear resistance in currency production. The development of coinage bronze reflects advancements in metallurgy that enabled ancient civilizations to produce standardized coinage, facilitating trade and economic growth.

Common Alloy Compositions: Coinage vs Industrial Bronze

Coinage bronze typically consists of an alloy with 88% copper, 9% tin, and 3% zinc, optimized for durability and corrosion resistance in minted coins. Industrial bronze alloys often vary widely, containing copper combined with tin, aluminum, manganese, or silicon depending on application requirements such as wear resistance or strength. Common industrial compositions include aluminum bronze with around 90% copper and 10% aluminum, designed for heavy-duty mechanical components.

Mechanical Properties and Durability Comparison

Coinage bronze, typically composed of 88% copper and 12% tin, exhibits excellent hardness and resistance to wear, making it ideal for minting durable coins that withstand frequent handling. Industrial bronze alloys often include additional elements such as aluminum, manganese, or nickel, enhancing tensile strength, corrosion resistance, and fatigue life for demanding mechanical applications. While coinage bronze prioritizes surface durability and aesthetic appeal, industrial bronze offers superior mechanical properties like increased tensile strength and enhanced resistance to environmental degradation, ensuring long-term structural performance.

Corrosion Resistance in Coinage and Industrial Applications

Coinage bronze, primarily composed of copper and tin, offers excellent corrosion resistance essential for preserving the appearance and integrity of coins over time. Industrial bronze alloys often include additives like aluminum, silicon, or manganese to enhance corrosion resistance under harsh environmental conditions, such as marine or chemical exposures. These tailored compositions ensure that industrial bronze maintains durability and longevity in applications requiring resistance to oxidation and wear.

Casting and Manufacturing Differences

Coinage bronze, typically composed of 88% copper and 12% tin, is alloyed for high durability and corrosion resistance, making it ideal for detailed, small-scale coin casting using precision molds. Industrial bronze often includes additional elements like aluminum, manganese, or nickel, enhancing mechanical strength and wear resistance, suited for large-scale casting processes such as sand or investment casting in heavy machinery components. Casting coinage bronze demands fine-grain structure and smooth finishes to preserve intricate designs, whereas industrial bronze prioritizes structural integrity and fatigue resistance for functional parts.

Typical Uses of Bronze in Currency Production

Coinage bronze, typically composed of 88% copper and 12% tin, is prized for its durability and corrosion resistance, making it ideal for minting coins that withstand frequent handling and circulation. Industrial bronze alloys, often containing additional elements like aluminum or nickel, are tailored for mechanical applications rather than currency due to their enhanced strength and wear resistance. The distinct composition of coinage bronze ensures consistent weight and color, essential for maintaining monetary value and anti-counterfeiting measures in currency production.

Industrial Applications of Bronze Alloys

Industrial bronze alloys offer exceptional corrosion resistance, high strength, and excellent wear properties, making them ideal for marine hardware, bearings, and electrical connectors. Their alloy compositions, often including elements like aluminum, silicon, or manganese, enhance durability and thermal conductivity critical for heavy machinery and aerospace components. Compared to coinage bronze, industrial bronze prioritizes functional performance and mechanical stability in harsh environments over aesthetic appeal.

Cost Considerations: Coinage vs Industrial Bronze

Coinage bronze typically incurs higher costs due to its precise alloy composition and strict quality standards for durability and aesthetics in currency production. Industrial bronze, while more cost-effective, prioritizes mechanical properties and corrosion resistance for applications such as bearings and marine hardware. Cost considerations hinge on the balance between specialized alloy formulations needed for coinage versus the bulk material expenses typical in industrial manufacturing.

Choosing the Right Bronze for Your Application

Coinage bronze, primarily composed of copper, tin, and zinc, is valued for its durability and corrosion resistance, making it ideal for minting coins and decorative objects. Industrial bronze contains additional elements such as aluminum or phosphorus to enhance strength and wear resistance, suited for heavy machinery and construction applications. Selecting the right bronze depends on factors like mechanical requirements, environmental exposure, and electrical conductivity to ensure optimal performance and longevity.

Coinage Bronze vs Industrial Bronze Infographic

materialdif.com

materialdif.com