Bronze alloy, composed primarily of copper combined with tin and other metals, offers enhanced hardness, strength, and corrosion resistance compared to pure copper. While pure copper is highly conductive and malleable, bronze provides superior durability and wear resistance, making it ideal for tools, sculptures, and marine applications. The addition of alloying elements transforms copper's physical properties, resulting in a metal that balances workability with increased mechanical performance.

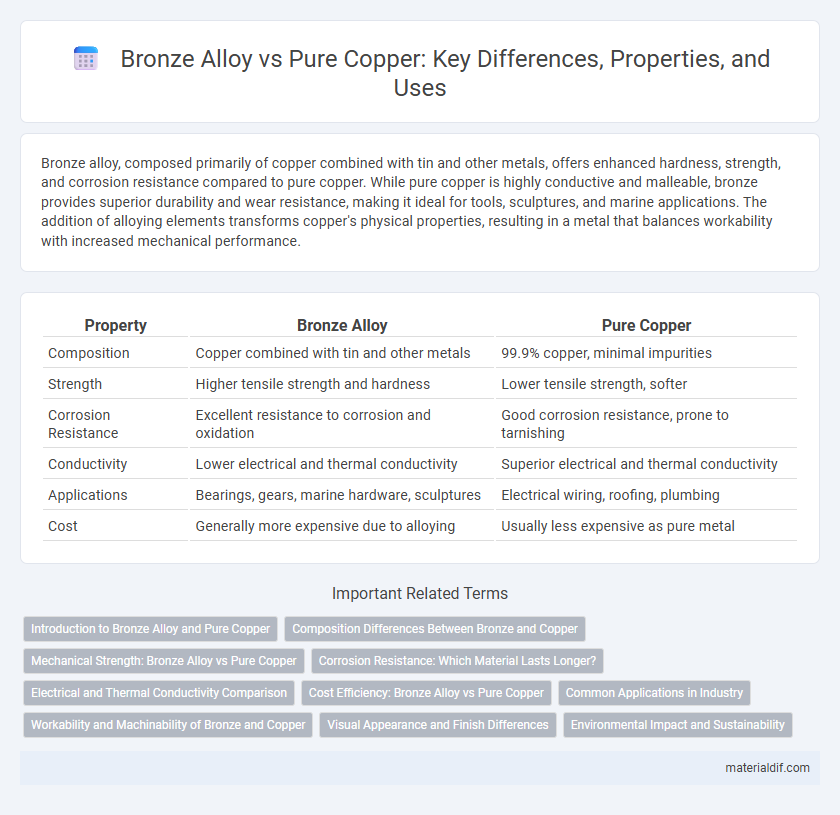

Table of Comparison

| Property | Bronze Alloy | Pure Copper |

|---|---|---|

| Composition | Copper combined with tin and other metals | 99.9% copper, minimal impurities |

| Strength | Higher tensile strength and hardness | Lower tensile strength, softer |

| Corrosion Resistance | Excellent resistance to corrosion and oxidation | Good corrosion resistance, prone to tarnishing |

| Conductivity | Lower electrical and thermal conductivity | Superior electrical and thermal conductivity |

| Applications | Bearings, gears, marine hardware, sculptures | Electrical wiring, roofing, plumbing |

| Cost | Generally more expensive due to alloying | Usually less expensive as pure metal |

Introduction to Bronze Alloy and Pure Copper

Bronze alloy, primarily composed of copper and tin, offers enhanced strength, corrosion resistance, and durability compared to pure copper, which consists of nearly 100% copper and excels in electrical conductivity and malleability. The addition of tin to copper creates a harder material with greater wear resistance, ideal for applications such as tools, sculptures, and marine hardware. Pure copper remains preferred for electrical wiring and plumbing due to its superior thermal and electrical conductivity.

Composition Differences Between Bronze and Copper

Bronze alloy primarily consists of copper combined with tin, usually ranging from 12% to 12.5%, which significantly enhances its hardness and corrosion resistance compared to pure copper. Pure copper, on the other hand, is composed of approximately 99.9% copper, exhibiting excellent electrical and thermal conductivity but lower mechanical strength. The addition of elements like tin, and sometimes phosphorus, aluminum, or nickel in bronze, alters its composition to improve durability and wear resistance for industrial applications.

Mechanical Strength: Bronze Alloy vs Pure Copper

Bronze alloy exhibits significantly higher mechanical strength compared to pure copper due to the addition of elements such as tin, which enhance hardness and tensile resistance. The microstructure of bronze alloys provides improved wear resistance and durability, making them suitable for applications requiring structural integrity under stress. In contrast, pure copper offers superior electrical conductivity but lacks the mechanical robustness found in bronze alloys.

Corrosion Resistance: Which Material Lasts Longer?

Bronze alloy exhibits superior corrosion resistance compared to pure copper, primarily due to its combination of copper with tin and other elements, which enhances its durability in harsh environments. This makes bronze more resistant to oxidation, marine conditions, and industrial pollutants, prolonging its lifespan significantly. As a result, bronze is often preferred for outdoor sculptures, marine hardware, and architectural applications where longevity is critical.

Electrical and Thermal Conductivity Comparison

Bronze alloy exhibits lower electrical and thermal conductivity compared to pure copper due to the presence of alloying elements like tin, which disrupt the electron flow and heat transfer. Pure copper has an electrical conductivity of approximately 59.6 million Siemens per meter (MS/m) and thermal conductivity around 401 W/m*K, whereas typical bronze alloys range between 15 to 28 MS/m for electrical and 50 to 110 W/m*K for thermal conductivity. These differences make pure copper preferable for applications demanding maximum conductivity, while bronze alloy offers improved strength and corrosion resistance at the cost of reduced electrical and thermal performance.

Cost Efficiency: Bronze Alloy vs Pure Copper

Bronze alloy offers greater cost efficiency compared to pure copper due to its improved durability and resistance to corrosion, which reduces maintenance and replacement expenses. Bronze's composition typically includes tin and other elements that enhance strength while maintaining affordability for industrial and artistic applications. Pure copper, though highly conductive, tends to incur higher costs over time because of its softness and susceptibility to oxidation.

Common Applications in Industry

Bronze alloy, composed primarily of copper and tin, exhibits superior mechanical strength, corrosion resistance, and wear resistance compared to pure copper, making it ideal for industrial applications such as marine hardware, bearings, and gears. Pure copper, valued for its exceptional electrical and thermal conductivity, is predominantly used in electrical wiring, heat exchangers, and plumbing systems. The enhanced durability and reduced friction of bronze alloys extend the lifespan of machinery components, while copper's conductivity properties are critical for efficient energy transmission and heat dissipation.

Workability and Machinability of Bronze and Copper

Bronze alloys exhibit superior machinability compared to pure copper due to their composition, which typically includes tin and other elements that enhance hardness and reduce ductility. The workability of bronze is often preferred in industrial applications because it offers greater strength and wear resistance while still allowing for efficient shaping and machining processes. Pure copper, although highly ductile and corrosion-resistant, tends to be softer and more prone to deformation, making it less suitable for precision machining and demanding mechanical applications.

Visual Appearance and Finish Differences

Bronze alloy typically exhibits a richer, more varied color palette ranging from reddish-brown to golden hues, enhanced by its tin and other metal content, unlike pure copper's uniform reddish-orange tone. The finish on bronze often appears more matte and textured due to its alloy composition, while pure copper tends to have a smoother, shinier surface that develops a distinct greenish patina over time. These visual and finish differences make bronze favored for artistic and decorative applications where depth and character are essential.

Environmental Impact and Sustainability

Bronze alloy, composed primarily of copper and tin, offers enhanced durability and corrosion resistance compared to pure copper, reducing the frequency of replacement and minimizing resource extraction impacts. The substitution of tin for a portion of copper in bronze decreases the overall demand for copper mining, which is often associated with significant environmental degradation and high energy consumption. Recycling bronze alloys is more efficient and sustainable due to their stable composition and resistance to oxidation, leading to lower carbon footprints in manufacturing compared to processing pure copper.

Bronze Alloy vs Pure Copper Infographic

materialdif.com

materialdif.com