Forged bronze offers superior strength and durability due to the metal's grain structure being aligned during the forging process, making it ideal for heavy-duty applications. Extruded bronze, produced by pushing the material through a die, provides precise dimensional control and consistency, which is beneficial for complex shapes and detailed components. Choosing between forged and extruded bronze depends on the specific mechanical requirements and manufacturing precision needed for the project.

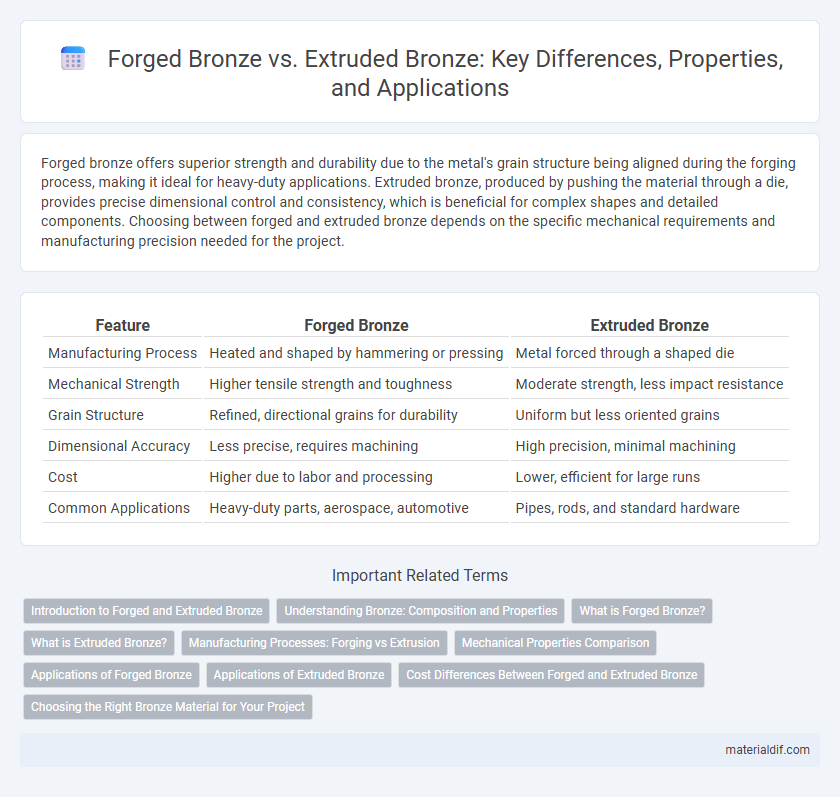

Table of Comparison

| Feature | Forged Bronze | Extruded Bronze |

|---|---|---|

| Manufacturing Process | Heated and shaped by hammering or pressing | Metal forced through a shaped die |

| Mechanical Strength | Higher tensile strength and toughness | Moderate strength, less impact resistance |

| Grain Structure | Refined, directional grains for durability | Uniform but less oriented grains |

| Dimensional Accuracy | Less precise, requires machining | High precision, minimal machining |

| Cost | Higher due to labor and processing | Lower, efficient for large runs |

| Common Applications | Heavy-duty parts, aerospace, automotive | Pipes, rods, and standard hardware |

Introduction to Forged and Extruded Bronze

Forged bronze is created by shaping heated bronze alloy under compressive forces, resulting in a dense, strong material ideal for high-stress applications. Extruded bronze is produced by forcing heated bronze through a die, forming continuous lengths with consistent cross-sections, suitable for uniform profiles and complex shapes. Both processes enhance bronze's mechanical properties but differ in grain structure, strength, and dimensional capabilities.

Understanding Bronze: Composition and Properties

Forged bronze is created by shaping heated bronze alloy, typically composed of copper and tin, offering superior strength and wear resistance due to its refined grain structure. Extruded bronze, produced by forcing the alloy through a die, provides consistent dimensional accuracy and improved surface finish while maintaining excellent corrosion resistance. Understanding the distinct microstructures and mechanical properties of forged versus extruded bronze helps in selecting the optimal material for applications requiring durability and performance.

What is Forged Bronze?

Forged bronze is a metal alloy shaped through a hammering or pressing process that enhances its structural integrity and strength by refining its grain structure. This method typically results in a denser, more durable material compared to extruded bronze, making it ideal for high-stress applications like bearings, bushings, and heavy-duty mechanical components. Forged bronze also exhibits improved resistance to wear and corrosion, providing longevity in demanding environments.

What is Extruded Bronze?

Extruded bronze is a type of bronze alloy shaped by forcing molten metal through a die to create long, continuous profiles with consistent cross-sections. This process enhances mechanical properties such as strength and durability, making extruded bronze ideal for precision components in industrial applications. Compared to forged bronze, extruded bronze offers superior uniformity and dimensional accuracy, crucial for complex geometries and high-performance uses.

Manufacturing Processes: Forging vs Extrusion

Forged bronze involves shaping the metal through localized compressive forces, resulting in a dense and structurally robust material with superior grain flow characteristics. Extruded bronze is produced by forcing the metal through a die, creating uniform cross-sectional profiles with consistent mechanical properties but less refinement in grain structure. The forging process enhances strength and fatigue resistance, while extrusion offers precision and efficiency for complex shapes.

Mechanical Properties Comparison

Forged bronze exhibits superior mechanical properties compared to extruded bronze, including enhanced tensile strength and improved wear resistance due to its denser grain structure formed under high pressure. The forging process aligns the metal's grain flow, resulting in greater toughness and fatigue resistance, making forged bronze ideal for high-stress applications. In contrast, extruded bronze, shaped by forcing the metal through a die, typically has lower tensile strength and ductility but offers better dimensional accuracy and surface finish.

Applications of Forged Bronze

Forged bronze offers superior strength and durability, making it ideal for high-stress applications such as industrial machinery components, aerospace parts, and heavy-duty connectors. Its enhanced grain structure and reduced porosity provide excellent wear resistance and fatigue strength, which are crucial for load-bearing and safety-critical components. Common applications include valve bodies, gears, bearing brackets, and marine hardware where reliability and performance under pressure are essential.

Applications of Extruded Bronze

Extruded bronze is widely used in applications requiring precise dimensions and smooth surface finishes, such as bearings, bushings, and electrical connectors. Its manufacturing process enhances mechanical properties like strength and wear resistance, making it ideal for heavy-duty industrial components and automotive parts. Compared to forged bronze, extruded bronze offers superior consistency and machinability, which benefits high-performance machinery and aerospace applications.

Cost Differences Between Forged and Extruded Bronze

Forged bronze generally incurs higher costs due to the labor-intensive process that enhances mechanical strength and durability, making it suitable for high-stress applications. Extruded bronze offers a cost-effective alternative by producing uniform shapes through a continuous process, reducing material waste and machining time. The choice between forged and extruded bronze balances initial fabrication expenses with long-term performance requirements and application-specific demands.

Choosing the Right Bronze Material for Your Project

Forged bronze offers superior strength and durability due to its refined grain structure, making it ideal for high-stress applications such as bearings and marine hardware. Extruded bronze provides better dimensional accuracy and surface finish, which benefits projects requiring precise shapes and smoother surfaces, like architectural components. Selecting the right bronze material depends on balancing mechanical performance needs with manufacturing tolerances and cost considerations.

Forged Bronze vs Extruded Bronze Infographic

materialdif.com

materialdif.com