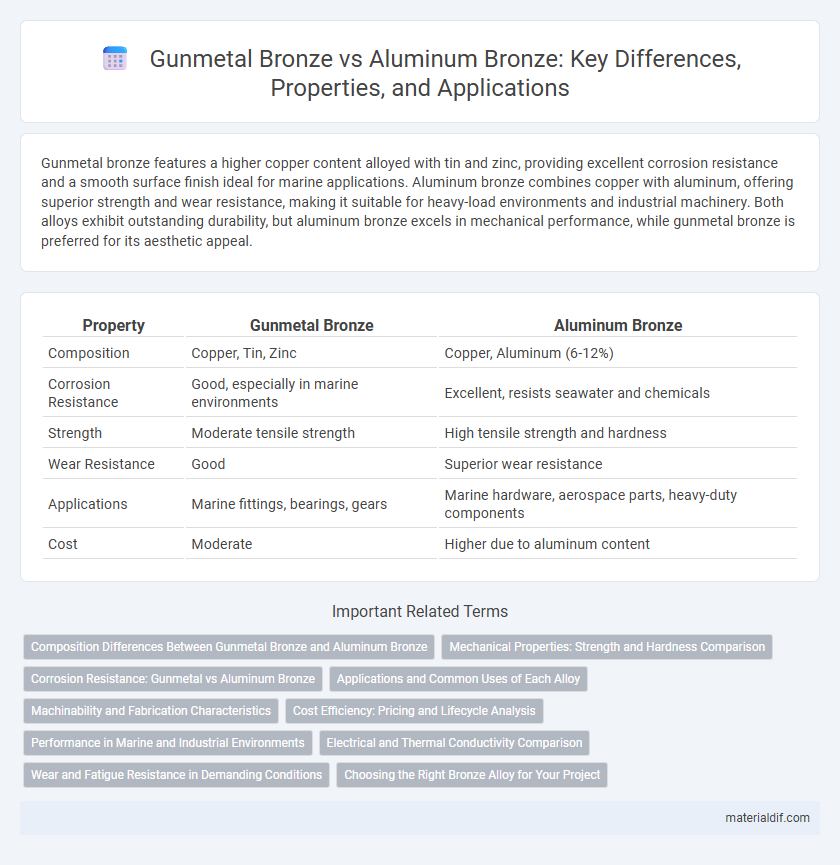

Gunmetal bronze features a higher copper content alloyed with tin and zinc, providing excellent corrosion resistance and a smooth surface finish ideal for marine applications. Aluminum bronze combines copper with aluminum, offering superior strength and wear resistance, making it suitable for heavy-load environments and industrial machinery. Both alloys exhibit outstanding durability, but aluminum bronze excels in mechanical performance, while gunmetal bronze is preferred for its aesthetic appeal.

Table of Comparison

| Property | Gunmetal Bronze | Aluminum Bronze |

|---|---|---|

| Composition | Copper, Tin, Zinc | Copper, Aluminum (6-12%) |

| Corrosion Resistance | Good, especially in marine environments | Excellent, resists seawater and chemicals |

| Strength | Moderate tensile strength | High tensile strength and hardness |

| Wear Resistance | Good | Superior wear resistance |

| Applications | Marine fittings, bearings, gears | Marine hardware, aerospace parts, heavy-duty components |

| Cost | Moderate | Higher due to aluminum content |

Composition Differences Between Gunmetal Bronze and Aluminum Bronze

Gunmetal bronze primarily consists of copper, tin, and zinc, with small amounts of lead or phosphorus to enhance machinability and strength. Aluminum bronze contains a higher proportion of aluminum, usually between 5% and 11%, along with copper and small amounts of iron or nickel to improve corrosion resistance and mechanical properties. The key compositional difference lies in the main alloying element--zinc in gunmetal bronze versus aluminum in aluminum bronze--resulting in distinct physical and chemical characteristics.

Mechanical Properties: Strength and Hardness Comparison

Gunmetal bronze exhibits superior strength and hardness compared to aluminum bronze, making it ideal for high-stress applications such as marine hardware and bearings. Aluminum bronze offers excellent corrosion resistance with moderately high strength, suitable for components exposed to harsh environments. The yield strength of gunmetal bronze typically ranges from 240 to 310 MPa, surpassing aluminum bronze's range of 180 to 270 MPa, while its hardness can reach up to 250 HB, compared to aluminum bronze's maximum of around 200 HB.

Corrosion Resistance: Gunmetal vs Aluminum Bronze

Gunmetal bronze exhibits strong corrosion resistance in marine and acidic environments due to its high copper and tin content with small amounts of zinc. Aluminum bronze offers superior corrosion resistance in seawater and industrial atmospheres, with enhanced protection against dezincification and pitting thanks to its aluminum alloying. Both alloys perform well in corrosive conditions, but aluminum bronze generally provides greater durability and resistance in highly oxidizing or saltwater applications.

Applications and Common Uses of Each Alloy

Gunmetal bronze, known for its excellent corrosion resistance and machinability, is commonly used in marine applications, valve components, and decorative hardware where durability and aesthetic appeal are essential. Aluminum bronze, featuring superior strength and resistance to wear and fatigue, finds widespread use in heavy machinery, aerospace fittings, and industrial valves subjected to high stress and abrasive environments. Both alloys serve critical roles in industries requiring robust metal solutions, with gunmetal preferred for precision parts and aluminum bronze favored for high-load applications.

Machinability and Fabrication Characteristics

Gunmetal bronze exhibits superior machinability compared to aluminum bronze due to its finer grain structure and lower work-hardening rate, allowing for smoother cutting and less tool wear. Aluminum bronze offers enhanced strength and corrosion resistance but is more challenging to machine, requiring slower speeds and specialized tooling to avoid galling and excessive tool wear. Both alloys are highly valued in fabrication, with gunmetal bronze preferred for applications demanding easier machining and aluminum bronze favored where mechanical durability and environmental resilience are critical.

Cost Efficiency: Pricing and Lifecycle Analysis

Gunmetal bronze, with its lower material cost and moderate strength, offers better upfront affordability compared to aluminum bronze, which commands a higher price due to superior corrosion resistance and durability. Aluminum bronze excels in lifecycle cost efficiency by reducing maintenance and replacement frequency in harsh environments, offsetting its initial expense over time. Evaluating total cost of ownership including procurement, maintenance, and longevity reveals aluminum bronze as the more cost-effective option for long-term, demanding applications.

Performance in Marine and Industrial Environments

Gunmetal bronze exhibits exceptional corrosion resistance and strength in marine environments, making it ideal for seawater applications such as ship fittings and propellers. Aluminum bronze offers superior wear resistance and mechanical strength, performing well under heavy load and abrasive industrial conditions. Both alloys resist biofouling and oxidation, but aluminum bronze's enhanced hardness provides greater durability in harsh industrial settings.

Electrical and Thermal Conductivity Comparison

Gunmetal bronze exhibits lower electrical conductivity compared to aluminum bronze, making it less suitable for electrical applications requiring efficient current flow. Aluminum bronze offers superior thermal conductivity, which enhances heat dissipation in components exposed to high temperatures. The distinct differences in conductivity properties influence the selection of these alloys in heat exchangers, electrical connectors, and industrial machinery.

Wear and Fatigue Resistance in Demanding Conditions

Gunmetal bronze exhibits superior wear resistance due to its high copper and tin content, making it ideal for applications requiring durability under friction. Aluminum bronze, enriched with aluminum, provides exceptional fatigue resistance and strength, especially in harsh, corrosive environments. Both alloys excel in demanding conditions, but aluminum bronze's ability to withstand cyclic stresses offers a distinct advantage in fatigue-critical components.

Choosing the Right Bronze Alloy for Your Project

Gunmetal bronze, composed primarily of copper, tin, and zinc, offers excellent corrosion resistance and machinability, making it ideal for precision components and marine applications. Aluminum bronze, enriched with aluminum, provides superior strength, wear resistance, and oxidation protection, suited for heavy-duty industrial parts and fasteners. Selecting between these bronzes depends on the project's demands for mechanical strength, environmental exposure, and specific performance requirements.

Gunmetal Bronze vs Aluminum Bronze Infographic

materialdif.com

materialdif.com