Cast bronze exhibits superior strength and complex shapes due to molten metal poured into molds, making it ideal for intricate sculptures and industrial components. Wrought bronze, formed through mechanical working such as hammering or rolling, offers enhanced ductility and toughness, suitable for applications requiring durability and flexibility. Choosing between cast and wrought bronze depends on the desired balance of detail, strength, and mechanical performance.

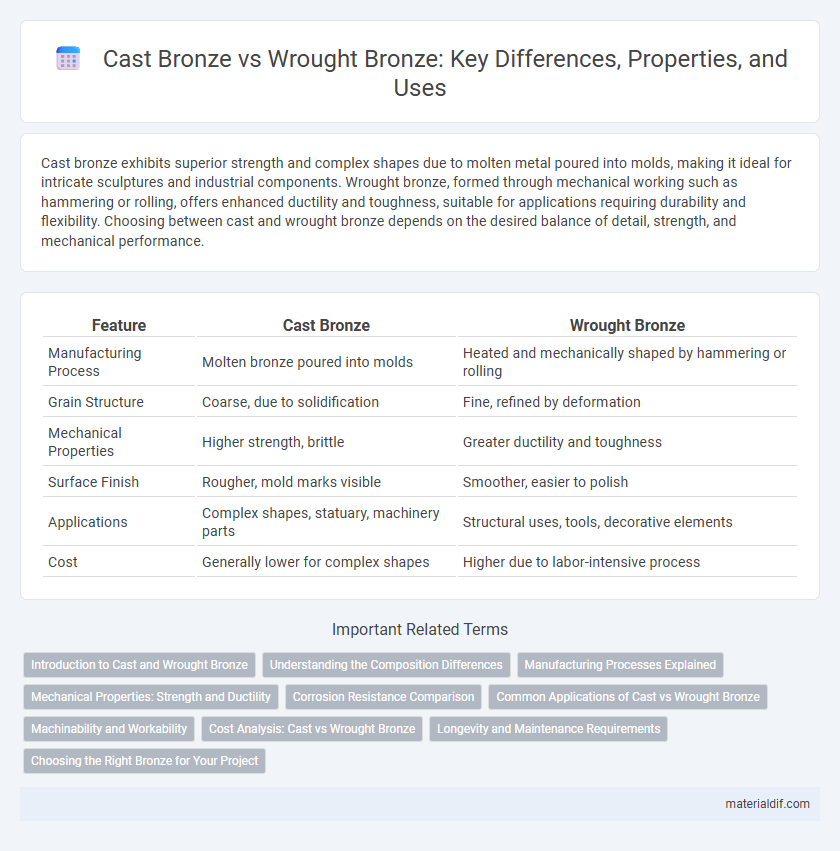

Table of Comparison

| Feature | Cast Bronze | Wrought Bronze |

|---|---|---|

| Manufacturing Process | Molten bronze poured into molds | Heated and mechanically shaped by hammering or rolling |

| Grain Structure | Coarse, due to solidification | Fine, refined by deformation |

| Mechanical Properties | Higher strength, brittle | Greater ductility and toughness |

| Surface Finish | Rougher, mold marks visible | Smoother, easier to polish |

| Applications | Complex shapes, statuary, machinery parts | Structural uses, tools, decorative elements |

| Cost | Generally lower for complex shapes | Higher due to labor-intensive process |

Introduction to Cast and Wrought Bronze

Cast bronze is produced by melting the alloy and pouring it into molds, allowing complex shapes and detailed designs that suit artistic and industrial purposes. Wrought bronze involves mechanically working the metal through processes like forging or rolling, which enhances strength and ductility, making it ideal for structural and mechanical applications. Both forms offer unique properties: cast bronze excels in precision and intricate patterns, while wrought bronze delivers superior toughness and wear resistance.

Understanding the Composition Differences

Cast bronze typically contains higher amounts of tin, ranging from 5% to 20%, which increases its hardness and makes it ideal for detailed molds and intricate designs. Wrought bronze, often consisting of about 5% tin with added elements like zinc or lead, exhibits improved ductility and malleability due to its mechanical working process. The differences in composition directly affect the material's metallurgical properties, influencing its suitability for various industrial and artistic applications.

Manufacturing Processes Explained

Cast bronze is produced by melting alloys and pouring them into molds, allowing precise shapes and detailed designs through controlled solidification. Wrought bronze involves mechanical working of solid bronze billets through processes like hammering, rolling, or extrusion, enhancing the metal's strength and ductility by aligning its grain structure. Both manufacturing methods influence the final properties and applications of bronze components, with cast bronze suited for intricate forms and wrought bronze preferred for structural uses requiring toughness.

Mechanical Properties: Strength and Ductility

Cast bronze typically exhibits higher compressive strength due to its dense, uniform microstructure formed during solidification, making it ideal for components requiring rigidity. Wrought bronze, processed through forging or rolling, demonstrates superior ductility and toughness, allowing it to withstand deformation without cracking. The mechanical properties of cast bronze favor strength, while wrought bronze balances strength with enhanced flexibility and impact resistance.

Corrosion Resistance Comparison

Cast bronze exhibits superior corrosion resistance compared to wrought bronze due to its denser microstructure and uniform alloy composition, which reduces susceptibility to environmental degradation. Wrought bronze, formed through mechanical working processes, may contain more impurities and microvoids that can accelerate corrosion when exposed to moisture and chemicals. Consequently, cast bronze is preferred in marine and industrial applications where enhanced durability against rust and oxidation is critical.

Common Applications of Cast vs Wrought Bronze

Cast bronze is widely used in applications requiring complex shapes and high strength, such as sculptures, marine hardware, and industrial machinery components due to its excellent castability and corrosion resistance. Wrought bronze, characterized by its enhanced toughness and ductility, finds common applications in architectural elements, musical instruments, and bearing components where precision and mechanical reliability are crucial. The selection between cast and wrought bronze is often determined by the specific mechanical properties and manufacturing requirements of the final product.

Machinability and Workability

Cast bronze offers superior machinability due to its uniform structure and ease of cutting, making it ideal for complex components requiring precision. Wrought bronze exhibits enhanced workability, allowing for extensive forging and shaping through mechanical processes, resulting in improved strength and toughness. Choosing between cast and wrought bronze depends on the specific application requirements for machinability or mechanical deformation.

Cost Analysis: Cast vs Wrought Bronze

Cast bronze typically incurs higher initial costs due to complex mold-making and casting processes, while wrought bronze demands more labor-intensive forging and finishing, impacting its overall expense. The cost-effectiveness of cast bronze is evident in large-scale production where economies of scale reduce unit costs, whereas wrought bronze remains costly in smaller quantities because of its manual fabrication. Material waste is generally lower in wrought bronze, potentially offsetting some expenses, but cast bronze offers more consistent dimensional accuracy, influencing cost decisions in precision applications.

Longevity and Maintenance Requirements

Cast bronze exhibits superior longevity due to its uniform structure and higher resistance to corrosion and wear, making it ideal for outdoor sculptures and industrial components. Wrought bronze, forged and worked for enhanced ductility, requires more frequent maintenance to prevent surface oxidation and deformation under stress. Regular cleaning and protective coatings extend the lifespan of both types, but cast bronze generally demands less intensive upkeep over time.

Choosing the Right Bronze for Your Project

Cast bronze offers superior strength and intricate detail, making it ideal for complex shapes and heavy-duty applications, while wrought bronze provides enhanced ductility and toughness, suitable for parts requiring bending or forging. Considering factors like mechanical properties, thermal conductivity, and corrosion resistance helps determine the best bronze type for your project's environmental and structural demands. Evaluating the intended use, fabrication process, and performance requirements ensures selecting the optimal bronze alloy for durability and functionality.

Cast Bronze vs Wrought Bronze Infographic

materialdif.com

materialdif.com