Rolled bronze features a uniform grain structure that enhances strength and durability, making it ideal for applications requiring consistent mechanical properties. Forged bronze offers superior toughness and resistance to impact due to its refined grain alignment achieved through controlled deformation. Choosing between rolled and forged bronze depends on the specific demands of the project, such as structural integrity versus formability.

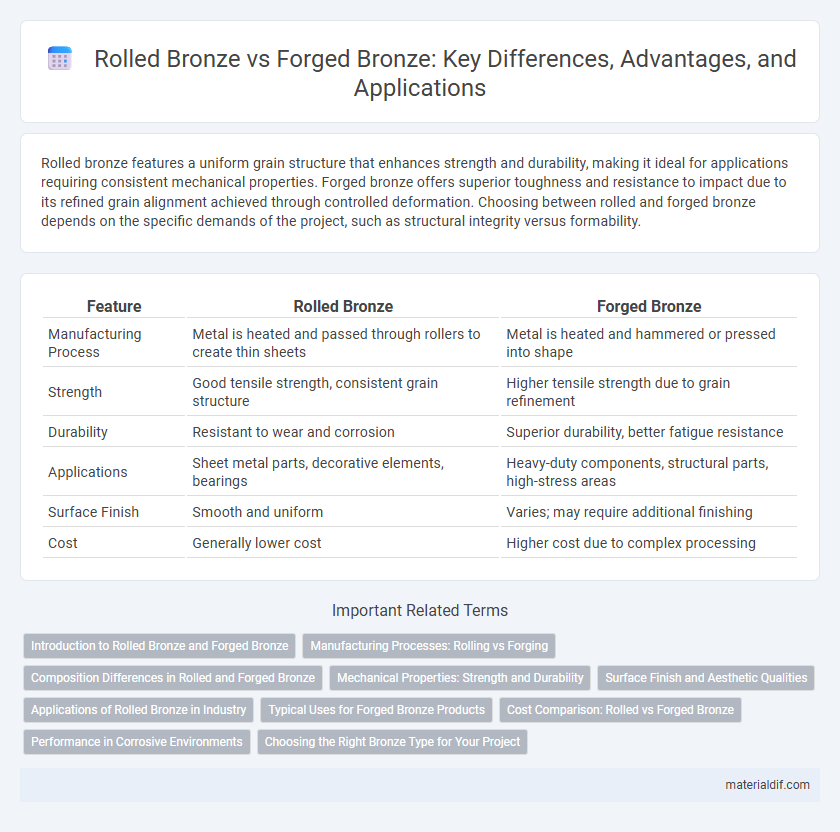

Table of Comparison

| Feature | Rolled Bronze | Forged Bronze |

|---|---|---|

| Manufacturing Process | Metal is heated and passed through rollers to create thin sheets | Metal is heated and hammered or pressed into shape |

| Strength | Good tensile strength, consistent grain structure | Higher tensile strength due to grain refinement |

| Durability | Resistant to wear and corrosion | Superior durability, better fatigue resistance |

| Applications | Sheet metal parts, decorative elements, bearings | Heavy-duty components, structural parts, high-stress areas |

| Surface Finish | Smooth and uniform | Varies; may require additional finishing |

| Cost | Generally lower cost | Higher cost due to complex processing |

Introduction to Rolled Bronze and Forged Bronze

Rolled bronze is produced by passing bronze slabs through rollers to achieve thinner, uniform sheets with consistent mechanical properties, ideal for applications requiring precise dimensions and smooth surfaces. Forged bronze, on the other hand, involves shaping bronze through hammering or pressing at high temperatures, resulting in enhanced strength and structural integrity suitable for load-bearing components. Both methods influence the bronze's microstructure and performance, making rolled bronze preferable for fine detail work and forged bronze optimal for robust, heavy-duty uses.

Manufacturing Processes: Rolling vs Forging

Rolled bronze is produced by passing heated bronze slabs through rollers to achieve uniform thickness and surface finish, enhancing its structural consistency and machinability. Forged bronze involves shaping heated bronze through repeated hammering or pressing, which refines its grain structure and increases strength and durability. The rolling process allows for precise thickness control and smoother surfaces, while forging improves mechanical properties and resistance to impact.

Composition Differences in Rolled and Forged Bronze

Rolled bronze typically contains a higher proportion of copper and tin, offering improved malleability and surface finish compared to forged bronze, which often has additional elements like zinc or phosphorus to enhance strength and durability. The forging process aligns the metal's grain structure, resulting in increased toughness, while rolling produces a denser and more uniform composition with fewer internal stresses. These compositional and structural differences impact the mechanical properties and suitability of each bronze type for specific industrial applications.

Mechanical Properties: Strength and Durability

Rolled bronze typically exhibits higher tensile strength and improved surface finish due to its uniform grain structure achieved through mechanical deformation, enhancing durability in wear-resistant applications. Forged bronze, however, offers superior impact resistance and toughness as the forging process refines the internal grain structure, resulting in enhanced fatigue strength for heavy-duty mechanical components. Both processes optimize mechanical properties differently, with rolled bronze favoring strength and surface hardness, while forged bronze excels in toughness and long-term durability under cyclic loads.

Surface Finish and Aesthetic Qualities

Rolled bronze exhibits a smoother and more uniform surface finish due to its production process, resulting in a consistent and polished appearance ideal for decorative applications. Forged bronze, however, often displays a more textured and rugged surface with subtle variations that can enhance its aesthetic appeal through a handcrafted look. The choice between rolled and forged bronze significantly impacts the final visual quality, with rolled bronze favored for sleek, refined finishes and forged bronze valued for its artisanal and robust character.

Applications of Rolled Bronze in Industry

Rolled bronze exhibits superior uniformity and surface finish, making it ideal for precision components in aerospace, automotive, and electrical industries. Its enhanced strength-to-weight ratio supports applications such as bushings, gears, and connectors where wear resistance and conductivity are critical. Industrial sectors prefer rolled bronze for streamlined manufacturing processes due to its predictable mechanical properties and reduced machining time.

Typical Uses for Forged Bronze Products

Forged bronze products are commonly used in heavy-duty applications such as industrial machinery, marine components, and bearing systems due to their superior strength and durability. Their enhanced mechanical properties make them ideal for parts subjected to high stress, including gears, valves, and shafts. These characteristics ensure forged bronze components maintain performance in demanding environments where rolled bronze may fall short.

Cost Comparison: Rolled vs Forged Bronze

Rolled bronze typically costs less than forged bronze due to its streamlined manufacturing process that involves rolling molten bronze into sheets, reducing labor and energy expenses. Forged bronze requires higher production costs as it involves heating and hammering the material to achieve desired shapes, which demands skilled labor and longer processing times. For applications where budget constraints are critical, rolled bronze offers a more cost-effective solution without significantly compromising strength or durability.

Performance in Corrosive Environments

Rolled bronze exhibits improved surface density and fewer voids compared to forged bronze, enhancing its corrosion resistance in harsh environments. Forged bronze, while mechanically stronger due to grain alignment, may be more susceptible to corrosive attack if surface treatments are inadequate. In marine or acidic conditions, rolled bronze provides superior durability and longevity by minimizing corrosive penetration through its compact microstructure.

Choosing the Right Bronze Type for Your Project

Rolled bronze features a uniform grain structure ideal for precision applications, while forged bronze offers superior strength and grain flow that enhances durability under stress. Selecting the right bronze type depends on project requirements such as mechanical strength, corrosion resistance, and dimensional stability. For components exposed to heavy loads or requiring maximal toughness, forged bronze is preferred; for detailed, thin designs, rolled bronze provides better surface finish and workability.

Rolled Bronze vs Forged Bronze Infographic

materialdif.com

materialdif.com