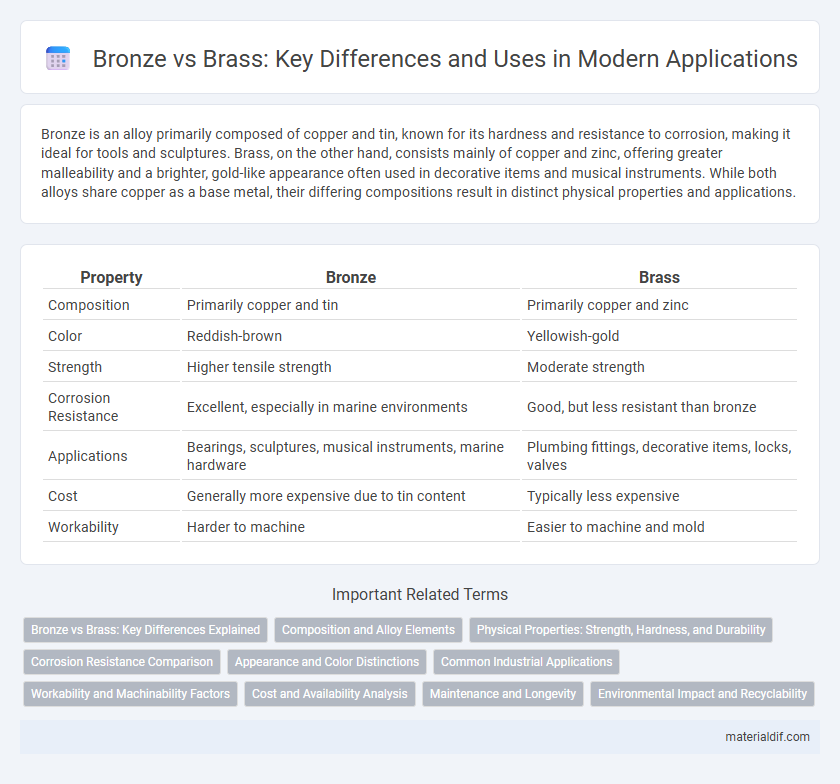

Bronze is an alloy primarily composed of copper and tin, known for its hardness and resistance to corrosion, making it ideal for tools and sculptures. Brass, on the other hand, consists mainly of copper and zinc, offering greater malleability and a brighter, gold-like appearance often used in decorative items and musical instruments. While both alloys share copper as a base metal, their differing compositions result in distinct physical properties and applications.

Table of Comparison

| Property | Bronze | Brass |

|---|---|---|

| Composition | Primarily copper and tin | Primarily copper and zinc |

| Color | Reddish-brown | Yellowish-gold |

| Strength | Higher tensile strength | Moderate strength |

| Corrosion Resistance | Excellent, especially in marine environments | Good, but less resistant than bronze |

| Applications | Bearings, sculptures, musical instruments, marine hardware | Plumbing fittings, decorative items, locks, valves |

| Cost | Generally more expensive due to tin content | Typically less expensive |

| Workability | Harder to machine | Easier to machine and mold |

Bronze vs Brass: Key Differences Explained

Bronze is an alloy primarily composed of copper and tin, known for its hardness, corrosion resistance, and durability, making it ideal for applications like sculptures and bearings. Brass consists mainly of copper and zinc, offering superior machinability and a lower melting point, which suits musical instruments and decorative items. The key differences lie in composition, mechanical properties, and typical uses, with bronze favored for strength and resistance, while brass is preferred for its malleability and acoustic qualities.

Composition and Alloy Elements

Bronze primarily consists of copper and tin, typically containing about 12% tin, which enhances its strength and corrosion resistance. Brass is an alloy of copper and zinc, with zinc percentages varying from 5% to 40%, giving it greater malleability and a brighter appearance than bronze. The presence of tin in bronze contributes to its hardness and durability, while the zinc in brass affects its color and machinability.

Physical Properties: Strength, Hardness, and Durability

Bronze typically exhibits greater strength and hardness compared to brass due to its higher tin content, which enhances its mechanical properties and wear resistance. Its durability in marine environments surpasses brass because bronze forms a stable oxide layer that protects against corrosion and metal fatigue. In contrast, brass, an alloy of copper and zinc, is softer and more malleable but less resistant to tarnishing and mechanical stress, making bronze the preferred choice for applications demanding long-term structural integrity.

Corrosion Resistance Comparison

Bronze exhibits superior corrosion resistance compared to brass due to its higher copper and tin content, which forms a more stable oxide layer protecting the metal from environmental damage. Brass, primarily an alloy of copper and zinc, is more prone to dezincification and corrosion in marine or acidic environments. This makes bronze a preferred choice for applications requiring long-term durability in harsh conditions.

Appearance and Color Distinctions

Bronze typically exhibits a deeper, reddish-brown hue due to its high copper content, while brass shows a brighter, more yellow-gold color from its higher zinc composition. The patina on bronze often develops a greenish or dark brown surface over time, contrasting with brass's tendency to maintain a shiny, golden finish. These distinct visual characteristics make bronze preferred for sculptures and antique items, whereas brass is commonly chosen for decorative hardware and musical instruments.

Common Industrial Applications

Bronze is widely used in industrial applications such as manufacturing bearings, bushings, and marine hardware due to its excellent corrosion resistance and strength. In contrast, brass is commonly employed for plumbing fittings, musical instruments, and decorative elements because of its superior machinability and antimicrobial properties. Both alloys serve distinct roles, with bronze favored for high-stress environments and brass chosen for applications requiring ease of shaping and aesthetic appeal.

Workability and Machinability Factors

Bronze exhibits superior workability compared to brass due to its higher tensile strength and resistance to wear, making it ideal for casting and forging applications. Brass offers better machinability with its lower hardness and reduced tool wear, facilitating faster production in CNC machining processes. Selecting between bronze and brass depends on the balance required between durability and ease of manufacturing in specific industrial uses.

Cost and Availability Analysis

Bronze typically costs more than brass due to its higher copper and tin content, making it less affordable for large-scale industrial applications. Brass, composed mainly of copper and zinc, is more widely available and cheaper to produce, benefiting from abundant zinc resources and more efficient manufacturing processes. Cost-effective brass alloys dominate markets where price and accessibility are critical factors, while bronze remains preferred for applications requiring superior corrosion resistance and strength despite its higher expense.

Maintenance and Longevity

Bronze offers superior corrosion resistance and requires less maintenance compared to brass, making it ideal for outdoor applications and marine environments. Its composition, primarily copper and tin, provides enhanced durability and longevity under harsh conditions. Brass, containing copper and zinc, tends to tarnish and may need more frequent cleaning and polishing to maintain its appearance.

Environmental Impact and Recyclability

Bronze, composed primarily of copper and tin, exhibits a lower environmental impact than brass, which contains copper and zinc, due to the less toxic nature of its components and more energy-efficient smelting processes. The recyclability of bronze is highly efficient, enabling repeated melting without significant degradation of its properties, reducing the need for raw material extraction. Brass recycling often involves more complex sorting and separation due to zinc content, potentially increasing environmental burden compared to bronze.

Bronze vs Brass Infographic

materialdif.com

materialdif.com