Manganese bronze offers superior strength and corrosion resistance, making it ideal for high-stress marine and industrial applications. Aluminium bronze delivers excellent wear resistance and outstanding toughness, often preferred for heavy-duty mechanical components. Both alloys provide excellent durability, but manganese bronze excels in toughness while aluminium bronze has better oxidation resistance.

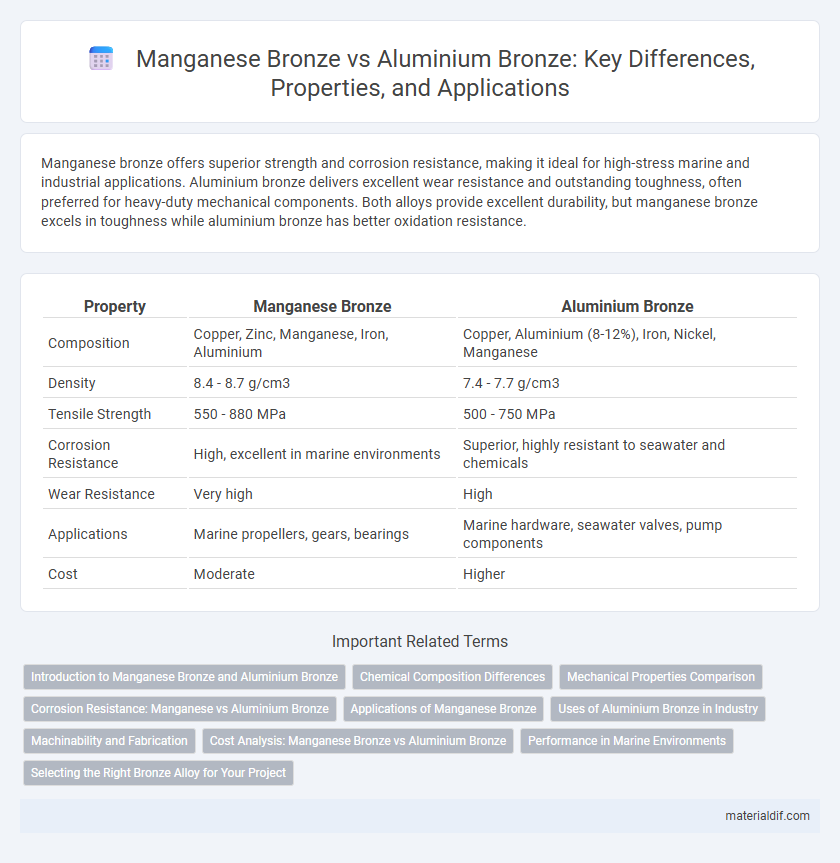

Table of Comparison

| Property | Manganese Bronze | Aluminium Bronze |

|---|---|---|

| Composition | Copper, Zinc, Manganese, Iron, Aluminium | Copper, Aluminium (8-12%), Iron, Nickel, Manganese |

| Density | 8.4 - 8.7 g/cm3 | 7.4 - 7.7 g/cm3 |

| Tensile Strength | 550 - 880 MPa | 500 - 750 MPa |

| Corrosion Resistance | High, excellent in marine environments | Superior, highly resistant to seawater and chemicals |

| Wear Resistance | Very high | High |

| Applications | Marine propellers, gears, bearings | Marine hardware, seawater valves, pump components |

| Cost | Moderate | Higher |

Introduction to Manganese Bronze and Aluminium Bronze

Manganese bronze is a high-strength alloy primarily composed of copper, zinc, and manganese, known for its excellent corrosion resistance and durability in marine applications. Aluminium bronze, containing copper and aluminum with small amounts of iron, nickel, or manganese, offers superior wear resistance and strength, making it ideal for heavy-duty industrial uses. Both alloys provide enhanced mechanical properties compared to traditional bronzes, with manganese bronze excelling in toughness and aluminium bronze standing out for its oxidation resistance.

Chemical Composition Differences

Manganese bronze primarily consists of copper, zinc, and manganese, with manganese content typically around 5-7%, enhancing strength and corrosion resistance. In contrast, aluminium bronze contains copper with 5-12% aluminium, which provides improved oxidation resistance and higher tensile strength. The key chemical difference lies in manganese's role as a strengthening agent in manganese bronze versus aluminium's contribution to wear and corrosion resistance in aluminium bronze.

Mechanical Properties Comparison

Manganese bronze offers superior tensile strength ranging from 700 to 900 MPa, making it ideal for high-stress applications, while aluminium bronze provides excellent corrosion resistance with tensile strength typically between 500 to 800 MPa. Aluminium bronze exhibits better wear resistance and higher hardness values around 250-320 HB compared to manganese bronze's 150-230 HB, enhancing its durability in abrasive environments. Both alloys maintain good fatigue strength, but manganese bronze tends to have slightly better machinability and ductility, facilitating easier fabrication in complex components.

Corrosion Resistance: Manganese vs Aluminium Bronze

Manganese bronze exhibits excellent corrosion resistance in marine and industrial environments due to its high copper content and manganese alloying, which enhances strength and wear resistance while providing protection against saltwater corrosion. Aluminium bronze outperforms manganese bronze in corrosion resistance, especially in highly aggressive environments like seawater and chemical exposure, because the aluminum forms a dense oxide layer that prevents further oxidation and metal degradation. Both alloys are chosen for corrosion-resistant applications, but aluminium bronze is preferred when superior resistance to oxidation and acidic conditions is critical.

Applications of Manganese Bronze

Manganese bronze exhibits exceptional strength, corrosion resistance, and fatigue properties, making it ideal for marine applications such as propellers, ship fittings, and valves. Its superior wear resistance and toughness also suit heavy-duty mechanical components including gears, bearings, and springs in automotive and industrial machinery. Unlike aluminum bronze, manganese bronze offers enhanced machinability and higher tensile strength, optimizing it for high-load, impact-resistant applications in demanding environments.

Uses of Aluminium Bronze in Industry

Aluminium bronze is widely used in marine, aerospace, and industrial applications due to its excellent corrosion resistance, high strength, and wear resistance. It is commonly employed for manufacturing ship propellers, valve components, and aircraft landing gear parts. The alloy's superior mechanical properties and resistance to seawater make it ideal for harsh environments where durability is critical.

Machinability and Fabrication

Manganese bronze offers superior machinability due to its composition of copper, zinc, and manganese, allowing for precise cutting and shaping with less tool wear, making it ideal for complex fabrication processes. Aluminium bronze, containing copper and aluminium, exhibits higher strength and corrosion resistance but tends to be tougher to machine, requiring specialized tools and slower speeds to achieve desired tolerances. Fabrication involving welding and casting also favors manganese bronze for easier handling, while aluminium bronze demands more controlled techniques to maintain structural integrity.

Cost Analysis: Manganese Bronze vs Aluminium Bronze

Manganese bronze typically costs more than aluminium bronze due to its higher alloying element content and enhanced mechanical properties. Aluminium bronze offers a more cost-effective solution with good corrosion resistance and reasonable strength, making it suitable for applications with budget constraints. When evaluating cost efficiency, factor in material price, machining costs, and lifecycle performance to determine the best fit for specific industrial uses.

Performance in Marine Environments

Manganese bronze exhibits superior strength and corrosion resistance, making it highly effective in harsh marine environments where saltwater exposure is constant. Aluminium bronze offers excellent resistance to seawater corrosion and biofouling, maintaining durability and performance over extended periods in marine applications. Both alloys provide enhanced wear resistance, but manganese bronze is preferred for heavy-duty marine components due to its higher tensile strength.

Selecting the Right Bronze Alloy for Your Project

Manganese bronze offers exceptional strength and corrosion resistance, ideal for heavy-duty marine and industrial applications, while aluminium bronze provides superior wear resistance and toughness, making it suitable for high-friction environments. Selecting the right bronze alloy depends on balancing mechanical properties, corrosion resistance, and environmental factors such as exposure to saltwater or heavy load conditions. Understanding the specific demands of your project ensures optimal performance and longevity by choosing manganese bronze for structural strength or aluminium bronze for durability and wear resistance.

Manganese Bronze vs Aluminium Bronze Infographic

materialdif.com

materialdif.com