Bronze alloys combine copper with elements like tin, aluminum, or phosphorus to enhance strength, corrosion resistance, and durability compared to pure bronze. These alloy variations offer improved machinability and tailored properties for specific industrial applications, making them more versatile than pure bronze. Pure bronze, primarily composed of copper and tin, is valued for its traditional aesthetic and excellent resistance to wear and corrosion in simpler uses.

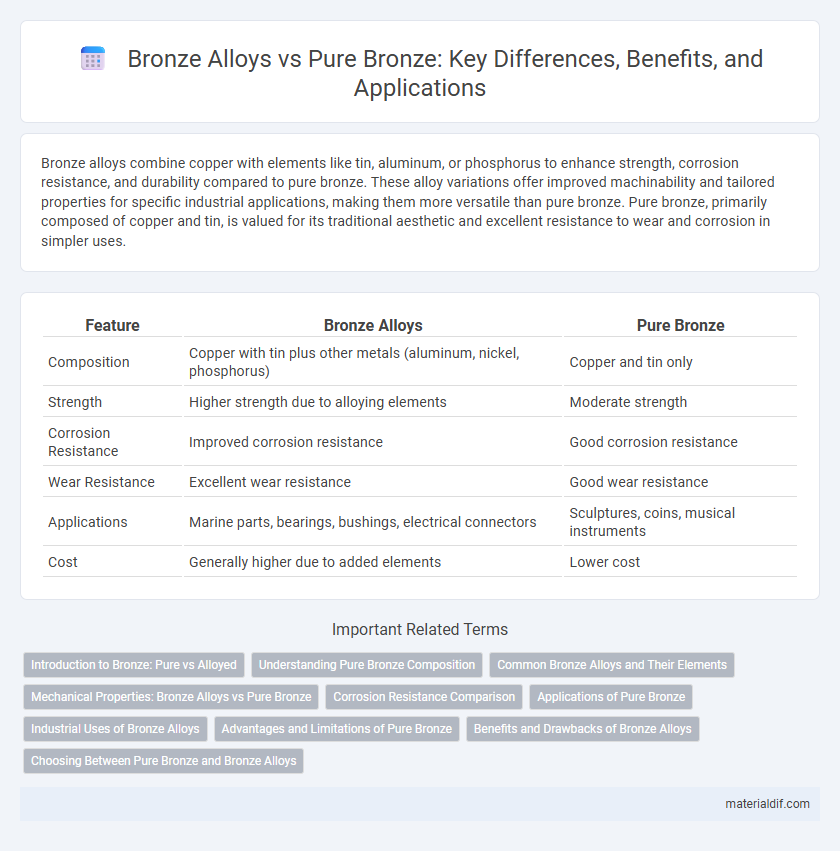

Table of Comparison

| Feature | Bronze Alloys | Pure Bronze |

|---|---|---|

| Composition | Copper with tin plus other metals (aluminum, nickel, phosphorus) | Copper and tin only |

| Strength | Higher strength due to alloying elements | Moderate strength |

| Corrosion Resistance | Improved corrosion resistance | Good corrosion resistance |

| Wear Resistance | Excellent wear resistance | Good wear resistance |

| Applications | Marine parts, bearings, bushings, electrical connectors | Sculptures, coins, musical instruments |

| Cost | Generally higher due to added elements | Lower cost |

Introduction to Bronze: Pure vs Alloyed

Bronze alloys typically combine copper with elements such as tin, aluminum, or phosphorus to enhance strength, corrosion resistance, and machinability compared to pure bronze, which is primarily copper and tin. Pure bronze offers a distinctive reddish-brown color and excellent corrosion resistance but lacks the mechanical durability found in alloyed variants. The specific composition of bronze alloys determines their suitability for applications ranging from marine hardware to artistic sculptures.

Understanding Pure Bronze Composition

Pure bronze primarily consists of approximately 88% copper and 12% tin, providing the foundational properties of this metal alloy. Bronze alloys incorporate additional elements such as aluminum, manganese, nickel, or phosphorus to enhance strength, corrosion resistance, and machinability. Understanding pure bronze composition is essential for applications requiring specific mechanical properties and traditional aesthetic qualities.

Common Bronze Alloys and Their Elements

Common bronze alloys typically include elements such as tin, aluminum, silicon, and phosphorus, each enhancing specific mechanical and corrosion-resistant properties compared to pure bronze. Tin, the primary alloying element, improves strength and wear resistance, while aluminum increases hardness and oxidation resistance. Silicon and phosphorus contribute to improved casting characteristics and increased stiffness, making these alloys more versatile for industrial applications than pure bronze.

Mechanical Properties: Bronze Alloys vs Pure Bronze

Bronze alloys typically exhibit superior mechanical properties compared to pure bronze, including increased tensile strength, hardness, and wear resistance due to the addition of elements like tin, aluminum, or phosphorus. Pure bronze, composed primarily of copper and tin, offers good corrosion resistance but generally lacks the enhanced durability and load-bearing capacity found in alloyed bronzes. These mechanical improvements make bronze alloys more suitable for industrial applications requiring high strength and longevity under stress.

Corrosion Resistance Comparison

Bronze alloys, which contain varying amounts of elements like aluminum, nickel, and phosphorus, exhibit enhanced corrosion resistance compared to pure bronze due to their improved chemical stability and protective oxide formation. Pure bronze, primarily composed of copper and tin, offers good corrosion resistance but is more susceptible to degradation in harsh environments such as marine or acidic conditions. The addition of alloying elements in bronze alloys significantly increases durability and longevity, making them preferable for industrial applications requiring superior resistance to corrosion.

Applications of Pure Bronze

Pure bronze, primarily composed of copper and tin, is valued for its excellent corrosion resistance and superior electrical conductivity, making it ideal for electrical connectors, marine hardware, and bearings. Its high thermal conductivity and non-magnetic properties enhance its use in heat exchangers and precision instruments. Although bronze alloys offer enhanced strength and wear resistance, pure bronze remains preferred in applications requiring minimal impurities and optimal corrosion performance.

Industrial Uses of Bronze Alloys

Bronze alloys, composed primarily of copper and tin with added elements such as aluminum, manganese, and phosphorus, offer enhanced strength, corrosion resistance, and wear resistance compared to pure bronze, making them ideal for demanding industrial applications. These alloys are extensively used in marine hardware, electrical connectors, and heavy machinery components due to their superior durability and conductivity. The tailored properties of bronze alloys ensure optimal performance in aerospace, automotive, and construction sectors where material reliability and longevity are critical.

Advantages and Limitations of Pure Bronze

Pure bronze, primarily composed of copper and tin, offers superior corrosion resistance and excellent thermal and electrical conductivity, making it ideal for applications requiring durability and heat dissipation. However, its mechanical strength and wear resistance are limited compared to bronze alloys, which often include elements like aluminum, manganese, or phosphorus to enhance hardness and tensile strength. Pure bronze is less versatile in demanding structural applications due to its lower machinability and susceptibility to deformation under heavy loads.

Benefits and Drawbacks of Bronze Alloys

Bronze alloys offer enhanced strength, corrosion resistance, and machinability compared to pure bronze, making them ideal for industrial applications such as bearings, gears, and marine hardware. However, the addition of elements like aluminum, nickel, or tin can increase production costs and reduce electrical conductivity, which might limit their use in electrical components. Pure bronze, though softer and less durable, provides better thermal and electrical conductivity and is easier to cast and machine for artistic and decorative purposes.

Choosing Between Pure Bronze and Bronze Alloys

Pure bronze, composed primarily of copper and tin, offers excellent corrosion resistance and a distinctive reddish-brown color ideal for decorative applications. Bronze alloys, which incorporate additional elements like aluminum, manganese, or phosphorus, provide enhanced mechanical strength, wear resistance, and improved machinability for industrial and structural uses. Selecting between pure bronze and bronze alloys depends on the specific requirements for durability, appearance, and performance in the intended application.

Bronze Alloys vs Pure Bronze Infographic

materialdif.com

materialdif.com