Bronze offers excellent machinability due to its relatively low hardness and good thermal conductivity, allowing for precise and efficient cutting processes. Its formability is also strong, enabling various shaping methods such as forging, rolling, and extrusion without compromising material integrity. Balancing machinability and formability, bronze is ideal for applications requiring detailed components and complex shapes.

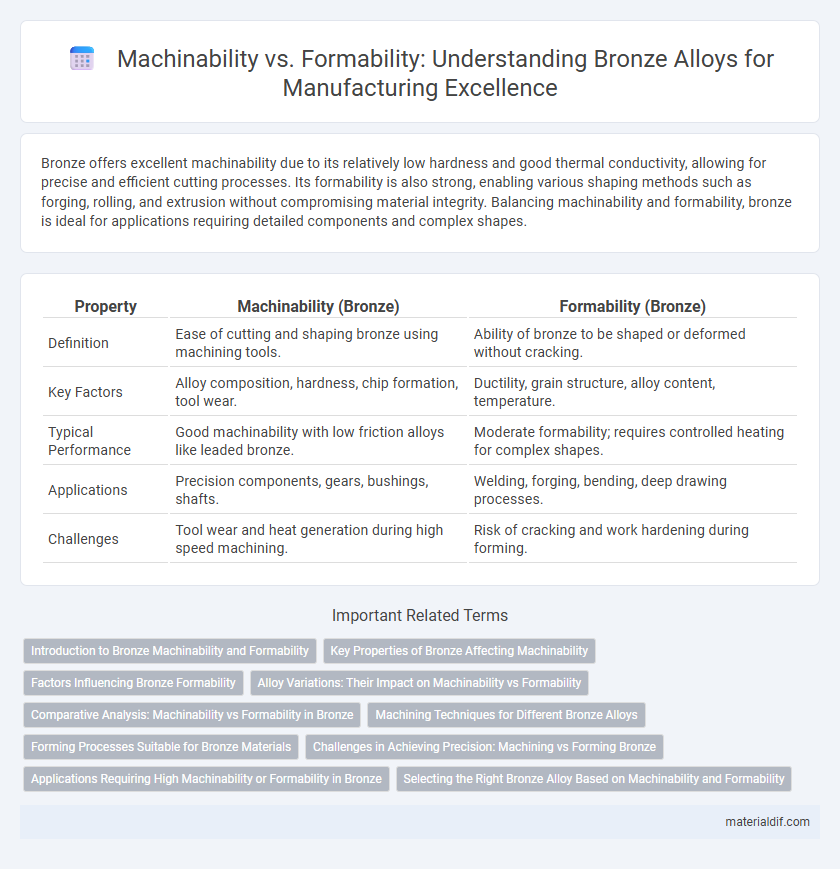

Table of Comparison

| Property | Machinability (Bronze) | Formability (Bronze) |

|---|---|---|

| Definition | Ease of cutting and shaping bronze using machining tools. | Ability of bronze to be shaped or deformed without cracking. |

| Key Factors | Alloy composition, hardness, chip formation, tool wear. | Ductility, grain structure, alloy content, temperature. |

| Typical Performance | Good machinability with low friction alloys like leaded bronze. | Moderate formability; requires controlled heating for complex shapes. |

| Applications | Precision components, gears, bushings, shafts. | Welding, forging, bending, deep drawing processes. |

| Challenges | Tool wear and heat generation during high speed machining. | Risk of cracking and work hardening during forming. |

Introduction to Bronze Machinability and Formability

Bronze exhibits excellent machinability due to its ability to produce smooth, precise cuts with minimal tool wear, making it ideal for intricate components and detailed manufacturing processes. Its formability varies depending on the specific alloy composition, with some bronze grades displaying superior malleability and ductility suitable for stamping and forging applications. Understanding the balance between bronze machinability and formability is essential for optimizing production efficiency and achieving high-quality finished products in industries like aerospace, marine, and electrical connectors.

Key Properties of Bronze Affecting Machinability

Bronze exhibits high machinability due to its moderate hardness and excellent thermal conductivity, which reduce tool wear and overheating during cutting processes. Its formability is impacted by the alloy's composition, with higher tin content generally decreasing ductility and complicating forming operations. The balance of elements such as copper, tin, and phosphorus directly influences grain structure, corrosion resistance, and mechanical strength, all critical factors in machining efficiency and formability performance.

Factors Influencing Bronze Formability

Bronze formability is influenced by alloy composition, grain structure, and temperature during processing. Higher copper content enhances ductility, while the presence of elements like tin and phosphorus increases strength but reduces malleability. Control of cooling rates and thermomechanical treatments further optimize bronze formability by refining microstructure and minimizing defects.

Alloy Variations: Their Impact on Machinability vs Formability

Bronze alloy variations, such as aluminum bronze, silicon bronze, and phosphor bronze, significantly affect machinability and formability, with aluminum bronze exhibiting lower machinability but superior strength and corrosion resistance compared to phosphor bronze. Silicon bronze offers better machinability but limited formability, making it ideal for precision machining applications, whereas phosphor bronze balances good machinability and excellent formability for deep drawing and intricate fabrication. Selecting the appropriate bronze alloy depends on the specific manufacturing requirements, balancing trade-offs between machining speed, tool wear, and the ability to form complex shapes without cracking.

Comparative Analysis: Machinability vs Formability in Bronze

Bronze exhibits moderate machinability due to its relatively low hardness and good thermal conductivity, allowing for efficient cutting and shaping with standard tooling. In contrast, its high formability stems from excellent ductility and resistance to wear, making it ideal for cold and hot forming processes. Comparing the two, bronze is better suited for forming complex shapes with minimal cracking while machining requires more careful tool selection to avoid excessive tool wear.

Machining Techniques for Different Bronze Alloys

Bronze alloys exhibit varying machinability depending on their composition, with aluminum bronze and manganese bronze offering excellent machining characteristics due to their uniform microstructure and hardness. Machining techniques such as turning, milling, and drilling require careful selection of cutting tools--carbide or high-speed steel--to optimize tool life and surface finish. Adjustments in cutting speed, feed rate, and coolant application are essential to account for differences in hardness and thermal conductivity among bronze alloys, ensuring precision and efficiency in manufacturing processes.

Forming Processes Suitable for Bronze Materials

Bronze exhibits excellent formability due to its good ductility and resistance to corrosion, making it suitable for various forming processes such as hot rolling, cold rolling, forging, and extrusion. Its ability to maintain strength and toughness during deformation allows precise shaping without compromising material integrity. These characteristics favor bronze in manufacturing components requiring complex shapes and high durability, including bearings, valves, and decorative items.

Challenges in Achieving Precision: Machining vs Forming Bronze

Machining bronze offers high precision with tight tolerances but faces challenges such as tool wear and heat generation that can affect surface finish and dimensional accuracy. Forming bronze, while providing excellent formability for complex shapes, struggles with maintaining consistent precision due to spring-back and die wear, which complicates achieving exact dimensions. Balancing machinability and formability requires optimizing process parameters to reduce defects and maintain dimensional stability in bronze components.

Applications Requiring High Machinability or Formability in Bronze

Bronze alloys exhibiting high machinability are preferred in precision components such as gears, bearings, and valves, where intricate shaping and tight tolerances are crucial. In contrast, bronze grades with superior formability find extensive use in decorative items, architectural hardware, and complex castings requiring extensive shaping and bending without cracking. Selecting the appropriate bronze alloy based on machinability or formability optimizes manufacturing efficiency and performance in applications across aerospace, marine, and automotive industries.

Selecting the Right Bronze Alloy Based on Machinability and Formability

Selecting the right bronze alloy requires balancing machinability and formability to meet specific manufacturing needs. High-phosphorus bronze offers excellent machinability for precision components, while aluminum bronze provides superior formability suitable for complex shapes and structural applications. Understanding these properties ensures optimal alloy selection for efficient processing and performance.

Machinability vs Formability (Bronze) Infographic

materialdif.com

materialdif.com