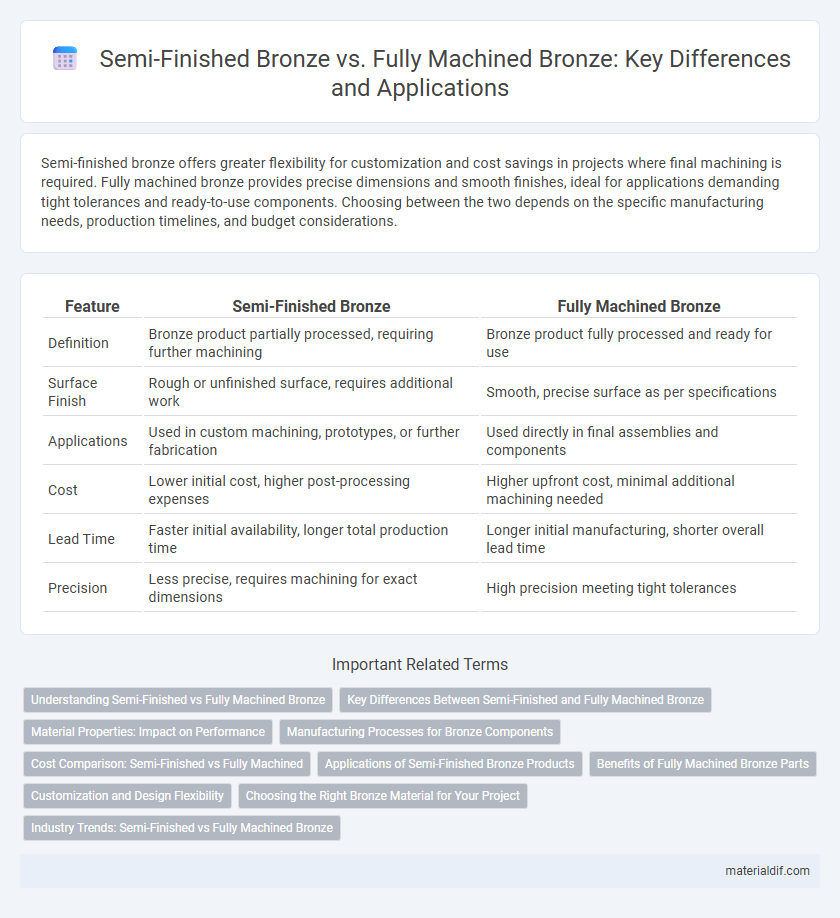

Semi-finished bronze offers greater flexibility for customization and cost savings in projects where final machining is required. Fully machined bronze provides precise dimensions and smooth finishes, ideal for applications demanding tight tolerances and ready-to-use components. Choosing between the two depends on the specific manufacturing needs, production timelines, and budget considerations.

Table of Comparison

| Feature | Semi-Finished Bronze | Fully Machined Bronze |

|---|---|---|

| Definition | Bronze product partially processed, requiring further machining | Bronze product fully processed and ready for use |

| Surface Finish | Rough or unfinished surface, requires additional work | Smooth, precise surface as per specifications |

| Applications | Used in custom machining, prototypes, or further fabrication | Used directly in final assemblies and components |

| Cost | Lower initial cost, higher post-processing expenses | Higher upfront cost, minimal additional machining needed |

| Lead Time | Faster initial availability, longer total production time | Longer initial manufacturing, shorter overall lead time |

| Precision | Less precise, requires machining for exact dimensions | High precision meeting tight tolerances |

Understanding Semi-Finished vs Fully Machined Bronze

Semi-finished bronze components retain a rough surface and require further machining or finishing to meet precise dimensional and functional specifications, offering flexibility for custom manufacturing processes. Fully machined bronze parts undergo complete machining and finishing, delivering ready-to-use products with exact tolerances and smooth finishes ideal for immediate application. Understanding the differences ensures optimal material selection for projects prioritizing either customizable processing or immediate deployment.

Key Differences Between Semi-Finished and Fully Machined Bronze

Semi-finished bronze products retain a rough surface and require further machining to meet specific dimensions or finish standards, offering flexibility for customized fabrication. Fully machined bronze components are precisely shaped and finished, providing ready-to-use parts with tight tolerances and smooth surfaces, ideal for immediate application in industrial assemblies. The key differences lie in production readiness, surface quality, and dimensional precision, which influence cost, lead time, and suitability for end-use functions.

Material Properties: Impact on Performance

Semi-finished bronze typically exhibits less precise dimensional tolerances and surface finishes compared to fully machined bronze, affecting its mechanical performance and wear resistance. Fully machined bronze parts undergo precise machining and heat treatments that enhance their hardness, tensile strength, and corrosion resistance, leading to superior durability and performance in demanding applications. Material microstructure and density variations between semi-finished and fully machined bronze directly influence their impact strength and fatigue life in industrial uses.

Manufacturing Processes for Bronze Components

Semi-finished bronze components undergo initial casting or extrusion, providing a basic shape that requires further machining to achieve precise dimensions and surface finishes. Fully machined bronze parts are fabricated through advanced CNC machining techniques, ensuring tight tolerances and complex geometries directly from the raw bronze material. Manufacturing processes for bronze components emphasize precision in machining to enhance mechanical properties, wear resistance, and dimensional accuracy for high-performance applications.

Cost Comparison: Semi-Finished vs Fully Machined

Semi-finished bronze products generally cost less upfront due to reduced machining labor and equipment time, making them ideal for projects with flexible tolerances. Fully machined bronze components, while higher in initial cost, offer precision and reduced post-processing, potentially lowering total assembly expenses. The cost comparison depends on production volume, complexity, and tolerance requirements, with semi-finished bronze favored for bulk, less intricate parts and fully machined bronze suited to high-precision, low-volume applications.

Applications of Semi-Finished Bronze Products

Semi-finished bronze products serve as essential raw materials in manufacturing sectors where further processing is required to meet specific design and performance criteria. These products are widely used in automotive components, electrical connectors, and industrial machinery due to their excellent corrosion resistance, thermal conductivity, and machinability. Semi-finished bronze enables customization and precision in applications requiring alloys with superior strength and wear resistance before final machining.

Benefits of Fully Machined Bronze Parts

Fully machined bronze parts offer superior precision and uniformity, ensuring optimal fit and performance in high-tolerance applications such as aerospace and automotive industries. Enhanced surface finish and dimensional accuracy reduce the need for secondary processing, increasing manufacturing efficiency and cost-effectiveness. These parts also exhibit improved mechanical properties and corrosion resistance due to controlled machining processes, extending service life in demanding environments.

Customization and Design Flexibility

Semi-finished bronze offers significant customization and design flexibility by allowing manufacturers to shape and machine components according to specific project requirements, enabling tailored dimensions and features. Fully machined bronze provides precise, ready-to-use parts with tight tolerances and fine surface finishes, minimizing post-processing efforts while limiting further customization options. Selecting between semi-finished and fully machined bronze depends on balancing design complexity, production timelines, and the need for bespoke adjustments during fabrication.

Choosing the Right Bronze Material for Your Project

Semi-finished bronze offers versatility for customization and cost-efficiency, making it ideal for projects requiring tailored machining and finishing. Fully machined bronze provides precision, consistent dimensions, and reduced lead times, suitable for applications needing exact tolerances and immediate usability. Selecting the right bronze material depends on project specifications, budget constraints, and the required level of precision and finish.

Industry Trends: Semi-Finished vs Fully Machined Bronze

Semi-finished bronze products dominate industry trends due to their cost-effectiveness and versatility in customization across sectors such as automotive, aerospace, and construction. Fully machined bronze parts are preferred for high-precision applications requiring tight tolerances and complex geometries, commonly found in aerospace and defense industries. Market analysis shows a growing demand for semi-finished bronze in scalable manufacturing processes, while fully machined bronze remains crucial for specialized, low-volume production.

Semi-Finished Bronze vs Fully Machined Bronze Infographic

materialdif.com

materialdif.com