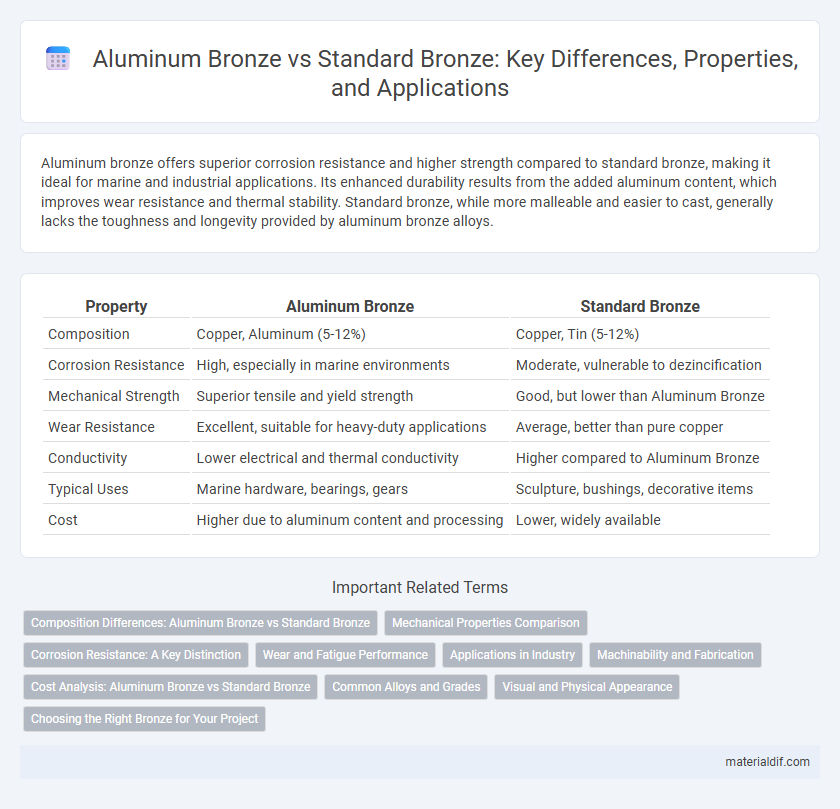

Aluminum bronze offers superior corrosion resistance and higher strength compared to standard bronze, making it ideal for marine and industrial applications. Its enhanced durability results from the added aluminum content, which improves wear resistance and thermal stability. Standard bronze, while more malleable and easier to cast, generally lacks the toughness and longevity provided by aluminum bronze alloys.

Table of Comparison

| Property | Aluminum Bronze | Standard Bronze |

|---|---|---|

| Composition | Copper, Aluminum (5-12%) | Copper, Tin (5-12%) |

| Corrosion Resistance | High, especially in marine environments | Moderate, vulnerable to dezincification |

| Mechanical Strength | Superior tensile and yield strength | Good, but lower than Aluminum Bronze |

| Wear Resistance | Excellent, suitable for heavy-duty applications | Average, better than pure copper |

| Conductivity | Lower electrical and thermal conductivity | Higher compared to Aluminum Bronze |

| Typical Uses | Marine hardware, bearings, gears | Sculpture, bushings, decorative items |

| Cost | Higher due to aluminum content and processing | Lower, widely available |

Composition Differences: Aluminum Bronze vs Standard Bronze

Aluminum bronze contains 5-11% aluminum combined with copper, enhancing strength, corrosion resistance, and wear properties compared to standard bronze, primarily composed of copper and tin or other elements such as phosphorus and manganese. The higher aluminum content forms a tough oxide layer on the surface, significantly improving oxidation resistance and making aluminum bronze ideal for marine and industrial applications. Standard bronze generally offers good machinability and corrosion resistance but lacks the elevated mechanical properties and durability found in aluminum bronze alloys.

Mechanical Properties Comparison

Aluminum bronze exhibits superior mechanical properties compared to standard bronze, offering higher tensile strength typically ranging from 550 to 750 MPa versus standard bronze's 300 to 500 MPa. Its enhanced hardness and excellent corrosion resistance contribute to improved wear resistance and durability in demanding applications. Aluminum bronze also maintains better fatigue strength and impact resistance, making it ideal for heavy-duty components in marine and industrial environments.

Corrosion Resistance: A Key Distinction

Aluminum bronze exhibits significantly higher corrosion resistance compared to standard bronze due to its alloy composition, which includes 5-11% aluminum that forms a robust oxide layer protecting the surface. This enhanced resistance makes aluminum bronze ideal for marine and industrial environments where exposure to seawater and chemicals is prevalent. In contrast, standard bronze, primarily composed of copper and tin, is more susceptible to oxidation and corrosion under similar conditions.

Wear and Fatigue Performance

Aluminum bronze exhibits superior wear resistance compared to standard bronze due to the presence of aluminum, which forms a hard oxide layer on the surface enhancing durability. Its fatigue strength surpasses that of standard bronze, making it ideal for high-stress applications requiring long-term performance under cyclic loading. The enhanced mechanical properties of aluminum bronze result from its unique microstructure, providing better resistance to deformation and surface degradation.

Applications in Industry

Aluminum bronze offers superior corrosion resistance and strength compared to standard bronze, making it ideal for marine and aerospace applications where durability under harsh conditions is critical. Standard bronze, with its excellent wear resistance and machinability, is widely used in bearings, bushings, and sculptures. Industries such as automotive, construction, and electrical manufacturing rely on aluminum bronze for components exposed to extreme stress and temperature variations.

Machinability and Fabrication

Aluminum bronze offers superior machinability compared to standard bronze due to its enhanced alloy composition, which includes aluminum providing better strength and wear resistance. Fabrication of aluminum bronze is generally easier, allowing for precision machining and forming without excessive tool wear or deformation. Standard bronze, while durable, often requires slower machining speeds and more frequent tool maintenance during fabrication processes.

Cost Analysis: Aluminum Bronze vs Standard Bronze

Aluminum bronze generally incurs higher material costs compared to standard bronze due to the addition of aluminum, which enhances strength and corrosion resistance. Standard bronze offers a more cost-effective option with adequate mechanical properties for many applications, resulting in lower overall expenses for manufacturing and maintenance. When evaluating cost efficiency, aluminum bronze's superior durability often offsets its initial price through reduced wear and longer service life in demanding environments.

Common Alloys and Grades

Aluminum bronze alloys typically contain 5-12% aluminum, enhancing corrosion resistance and mechanical strength compared to standard bronze, which is primarily a copper-tin alloy. Common grades of aluminum bronze, such as C95400 and C95500, are favored for their superior wear resistance and toughness in marine and industrial applications. Standard bronze grades like C93200 and C93800 offer good machinability and corrosion resistance but lack the high strength and oxidation resistance characteristic of aluminum bronze alloys.

Visual and Physical Appearance

Aluminum bronze exhibits a distinct golden-yellow color with a smooth, shiny surface, contrasting with the duller, reddish-brown tone of standard bronze. It has higher hardness and improved corrosion resistance, making it less prone to tarnishing or patina formation. The visual appeal of aluminum bronze often includes a polished, metallic sheen, while standard bronze shows a more matte and weathered look over time.

Choosing the Right Bronze for Your Project

Aluminum bronze offers superior corrosion resistance and higher strength compared to standard bronze, making it ideal for marine and industrial applications where durability is critical. Standard bronze typically contains a higher proportion of copper and tin, providing excellent machinability and good wear resistance, suitable for decorative and mechanical parts. Selecting aluminum bronze or standard bronze depends on project requirements such as environmental exposure, mechanical stress, and cost considerations.

Aluminum Bronze vs Standard Bronze Infographic

materialdif.com

materialdif.com