Bronze alloying enhances the metal's strength, durability, and resistance to corrosion compared to pure bronze, making it ideal for artistic sculptures and functional objects. The inclusion of elements like tin, aluminum, or phosphorus improves castability and surface finish, resulting in a more refined appearance and longer lifespan. Pure bronze, while aesthetically pleasing with its warm, reddish-brown hue, lacks the mechanical robustness that alloyed bronze provides for demanding applications.

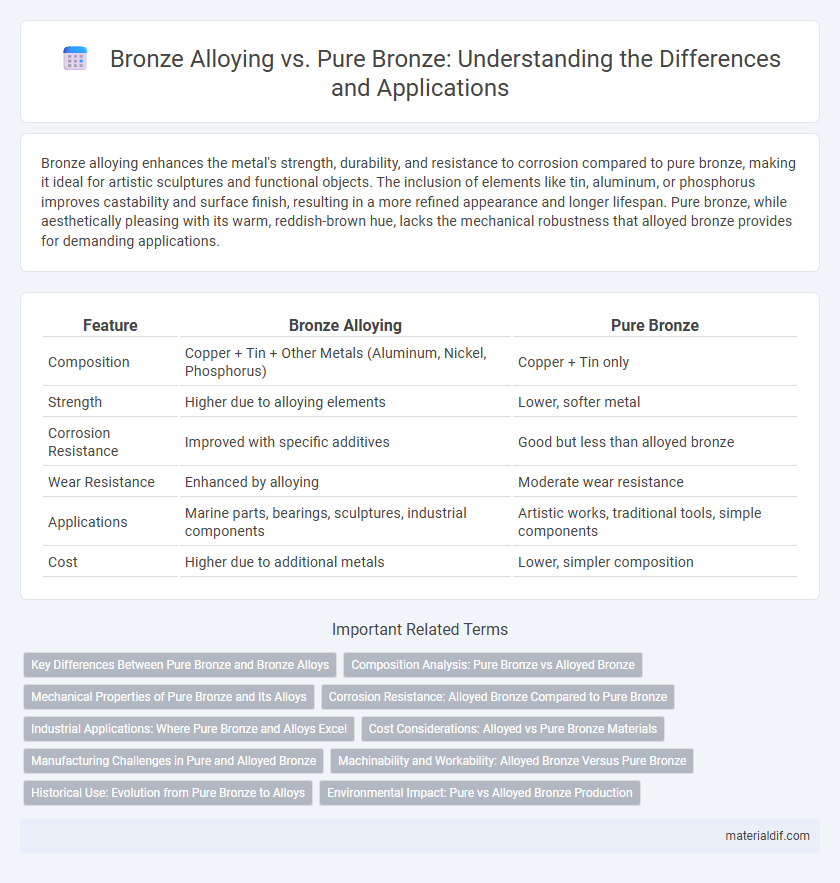

Table of Comparison

| Feature | Bronze Alloying | Pure Bronze |

|---|---|---|

| Composition | Copper + Tin + Other Metals (Aluminum, Nickel, Phosphorus) | Copper + Tin only |

| Strength | Higher due to alloying elements | Lower, softer metal |

| Corrosion Resistance | Improved with specific additives | Good but less than alloyed bronze |

| Wear Resistance | Enhanced by alloying | Moderate wear resistance |

| Applications | Marine parts, bearings, sculptures, industrial components | Artistic works, traditional tools, simple components |

| Cost | Higher due to additional metals | Lower, simpler composition |

Key Differences Between Pure Bronze and Bronze Alloys

Pure bronze primarily consists of copper and tin, offering high corrosion resistance and excellent thermal conductivity but limited mechanical strength. Bronze alloys incorporate additional elements such as aluminum, silicon, or phosphorus, enhancing hardness, wear resistance, and tensile strength for specialized industrial applications. The key difference lies in the alloying elements that tailor bronze's properties for specific performance requirements beyond the capabilities of pure bronze.

Composition Analysis: Pure Bronze vs Alloyed Bronze

Pure bronze primarily consists of approximately 88-95% copper and 5-12% tin, offering a uniform composition that enhances its corrosion resistance and electrical conductivity. Alloyed bronze incorporates additional elements such as aluminum, phosphorus, manganese, or silicon, which modify mechanical properties like strength, hardness, and wear resistance. Composition analysis reveals that alloyed bronze exhibits varied elemental percentages tailored to specific industrial applications, distinguishing its performance from pure bronze through targeted improvements in durability and machinability.

Mechanical Properties of Pure Bronze and Its Alloys

Pure bronze, primarily an alloy of copper and tin, exhibits moderate hardness and excellent corrosion resistance, making it suitable for decorative and architectural applications. Alloying bronze with elements such as aluminum, manganese, or phosphorus significantly enhances mechanical properties, including tensile strength, wear resistance, and fatigue durability, thereby expanding its usage in heavy-duty industrial components. Advanced bronze alloys like aluminum bronze demonstrate superior performance in high-stress environments due to improved hardness and oxidation resistance compared to pure bronze.

Corrosion Resistance: Alloyed Bronze Compared to Pure Bronze

Alloyed bronze exhibits superior corrosion resistance compared to pure bronze due to the addition of elements like tin, aluminum, and phosphorus, which enhance the metal's ability to withstand oxidizing environments. The presence of these alloying elements contributes to the formation of a more stable and protective oxide layer, reducing surface degradation in marine and industrial applications. Pure bronze, primarily composed of copper and tin, lacks these reinforcing properties, making it more susceptible to corrosion over time.

Industrial Applications: Where Pure Bronze and Alloys Excel

Pure bronze, composed primarily of copper and tin, offers excellent corrosion resistance and electrical conductivity, making it ideal for electrical connectors, marine fittings, and sculptures. Bronze alloys, enhanced with elements like aluminum, phosphorus, or silicon, provide superior strength, wear resistance, and machinability, optimizing their use in heavy-duty industrial components such as bearings, gears, and hydraulic cylinders. The tailored properties of bronze alloys enable broader application versatility and improved performance under mechanical stress compared to pure bronze.

Cost Considerations: Alloyed vs Pure Bronze Materials

Alloyed bronze typically costs less than pure bronze due to the inclusion of cheaper metals like aluminum, manganese, or silicon, which reduce overall material expenses while maintaining strength and corrosion resistance. Pure bronze, composed mainly of copper and tin, commands a higher price because of its higher copper content and superior traditional qualities. Cost considerations heavily influence the choice between alloyed and pure bronze, with alloyed options favored for budget-sensitive industrial applications requiring durability and cost-efficiency.

Manufacturing Challenges in Pure and Alloyed Bronze

Manufacturing pure bronze presents challenges such as limited mechanical strength and increased brittleness, which complicate casting and machining processes. Alloying bronze with elements like tin, aluminum, or phosphorus enhances durability, corrosion resistance, and machinability, enabling more reliable and versatile production techniques. The inclusion of alloying components requires precise control over composition to maintain material consistency and optimize manufacturing outcomes.

Machinability and Workability: Alloyed Bronze Versus Pure Bronze

Bronze alloying significantly enhances machinability by introducing elements such as tin, aluminum, and phosphorus that improve chip formation and reduce tool wear compared to pure bronze. Alloyed bronze exhibits superior workability, allowing for easier casting, forging, and machining processes, whereas pure bronze tends to be harder and less malleable. These alloying improvements make bronze alloys ideal for precision components requiring tight tolerances and complex shapes.

Historical Use: Evolution from Pure Bronze to Alloys

Early civilizations initially used pure bronze, an alloy of copper and tin, for tools and weapons due to its superior hardness compared to copper alone. Over time, the introduction of additional elements such as zinc, phosphorus, and aluminum enhanced bronze alloys, improving properties like corrosion resistance, strength, and castability. This evolution from pure bronze to complex alloys marked significant advances in metallurgy, enabling more durable and specialized artifacts throughout history.

Environmental Impact: Pure vs Alloyed Bronze Production

Pure bronze production generally results in lower carbon emissions compared to alloyed bronze due to simpler extraction and smelting processes. Alloying elements like aluminum, nickel, or tin require additional mining and refining, increasing the environmental footprint through higher energy consumption and waste generation. Recycling alloyed bronze, however, can mitigate some environmental impacts by reducing the need for raw material extraction and lowering overall resource depletion.

Bronze Alloying vs Pure Bronze Infographic

materialdif.com

materialdif.com