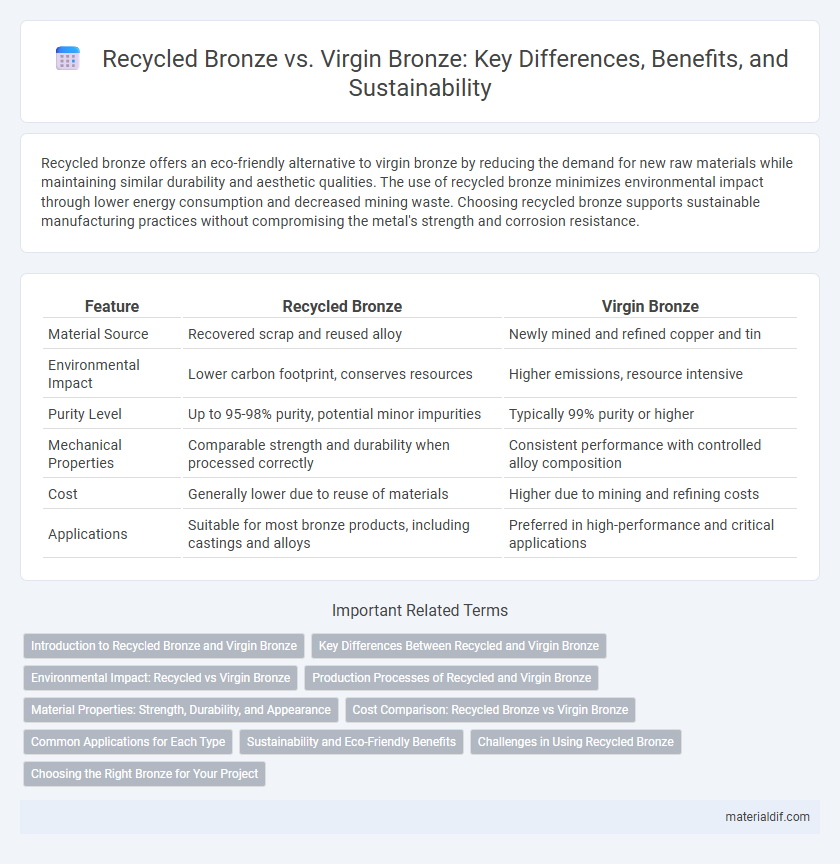

Recycled bronze offers an eco-friendly alternative to virgin bronze by reducing the demand for new raw materials while maintaining similar durability and aesthetic qualities. The use of recycled bronze minimizes environmental impact through lower energy consumption and decreased mining waste. Choosing recycled bronze supports sustainable manufacturing practices without compromising the metal's strength and corrosion resistance.

Table of Comparison

| Feature | Recycled Bronze | Virgin Bronze |

|---|---|---|

| Material Source | Recovered scrap and reused alloy | Newly mined and refined copper and tin |

| Environmental Impact | Lower carbon footprint, conserves resources | Higher emissions, resource intensive |

| Purity Level | Up to 95-98% purity, potential minor impurities | Typically 99% purity or higher |

| Mechanical Properties | Comparable strength and durability when processed correctly | Consistent performance with controlled alloy composition |

| Cost | Generally lower due to reuse of materials | Higher due to mining and refining costs |

| Applications | Suitable for most bronze products, including castings and alloys | Preferred in high-performance and critical applications |

Introduction to Recycled Bronze and Virgin Bronze

Recycled bronze is made by melting down scrap bronze materials, reducing environmental impact and conserving natural resources while maintaining comparable strength and durability to virgin bronze. Virgin bronze is produced from freshly mined copper and tin, ensuring high purity and consistent alloy composition for specialized applications requiring maximum corrosion resistance and mechanical properties. Choosing between recycled and virgin bronze depends on sustainability goals, cost considerations, and required performance characteristics in manufacturing or artistic projects.

Key Differences Between Recycled and Virgin Bronze

Recycled bronze is made by melting down existing bronze materials, significantly reducing energy consumption and environmental impact compared to virgin bronze, which is produced directly from raw ore. Virgin bronze tends to have a more consistent chemical composition and fewer impurities, resulting in superior mechanical properties and higher durability for critical applications. Recycled bronze offers cost savings and sustainability benefits but may exhibit slight variations in alloy quality due to mixed-source inputs.

Environmental Impact: Recycled vs Virgin Bronze

Recycled bronze significantly reduces environmental impact by lowering the demand for mining copper and tin, which are the primary raw materials in virgin bronze production. Mining activities for virgin bronze contribute to habitat destruction, soil erosion, and greenhouse gas emissions, whereas recycled bronze minimizes waste and conserves natural resources. Choosing recycled bronze supports sustainable manufacturing practices and decreases the overall carbon footprint associated with metal production.

Production Processes of Recycled and Virgin Bronze

Recycled bronze production involves melting down scrap bronze materials, reducing the need for raw ore extraction and lowering carbon emissions. Virgin bronze manufacturing requires mining and smelting fresh copper and tin ores, leading to higher energy consumption and environmental impact. Both processes demand precise alloy composition control to ensure the quality and durability of the final bronze product.

Material Properties: Strength, Durability, and Appearance

Recycled bronze maintains comparable strength and durability to virgin bronze due to its similar alloy composition, ensuring reliable performance in structural applications. The appearance of recycled bronze may exhibit slight variations in color and texture, influenced by impurities and oxidation during the recycling process. Both forms offer excellent corrosion resistance, but virgin bronze typically provides a more uniform finish ideal for high-precision or decorative uses.

Cost Comparison: Recycled Bronze vs Virgin Bronze

Recycled bronze typically costs 20-30% less than virgin bronze due to reduced energy consumption and raw material expenses in the recycling process. Virgin bronze requires mining and processing fresh copper and tin, leading to higher production costs and environmental impact. Manufacturing with recycled bronze not only lowers expenses but also supports sustainable practices by minimizing resource extraction and waste.

Common Applications for Each Type

Recycled bronze offers sustainable advantages and is commonly used in applications such as architectural elements, garden sculptures, and decorative hardware where environmental impact is a priority. Virgin bronze, prized for its consistent composition and superior mechanical properties, is preferred in high-performance components like marine fittings, electrical connectors, and precision instruments. Choosing between recycled and virgin bronze depends on the balance between cost, quality requirements, and environmental considerations in specific industrial and artistic applications.

Sustainability and Eco-Friendly Benefits

Recycled bronze significantly reduces the demand for raw copper and tin mining, lowering environmental impact and conserving natural resources. Its production consumes less energy and generates fewer greenhouse gas emissions compared to virgin bronze, enhancing sustainability in metal manufacturing. Choosing recycled bronze supports circular economy principles by minimizing waste and promoting responsible resource use.

Challenges in Using Recycled Bronze

Recycled bronze often contains impurities that can affect its mechanical properties and overall quality, posing challenges in maintaining consistent alloy standards. Variability in scrap sources creates difficulties in achieving uniform melting temperatures and alloy compositions during production. Contamination from mixed metals or coatings can degrade recyclability, increasing processing costs and complicating manufacturing workflows.

Choosing the Right Bronze for Your Project

Recycled bronze offers a sustainable and cost-effective alternative to virgin bronze, maintaining strong durability and corrosion resistance essential for industrial and artistic applications. Virgin bronze typically provides higher purity and consistency, making it ideal for projects requiring precise mechanical properties or intricate detailing. Evaluating project requirements for environmental impact, budget, and material performance ensures the right choice between recycled and virgin bronze.

Recycled Bronze vs Virgin Bronze Infographic

materialdif.com

materialdif.com