Machined bronze offers superior precision and strength due to its solid composition, making it ideal for high-stress applications requiring tight tolerances. Sintered bronze, produced through powder metallurgy, provides excellent porosity and self-lubricating properties, enhancing performance in bearing and friction applications. Choosing between machined and sintered bronze depends on balancing mechanical strength and lubrication needs for specific industrial uses.

Table of Comparison

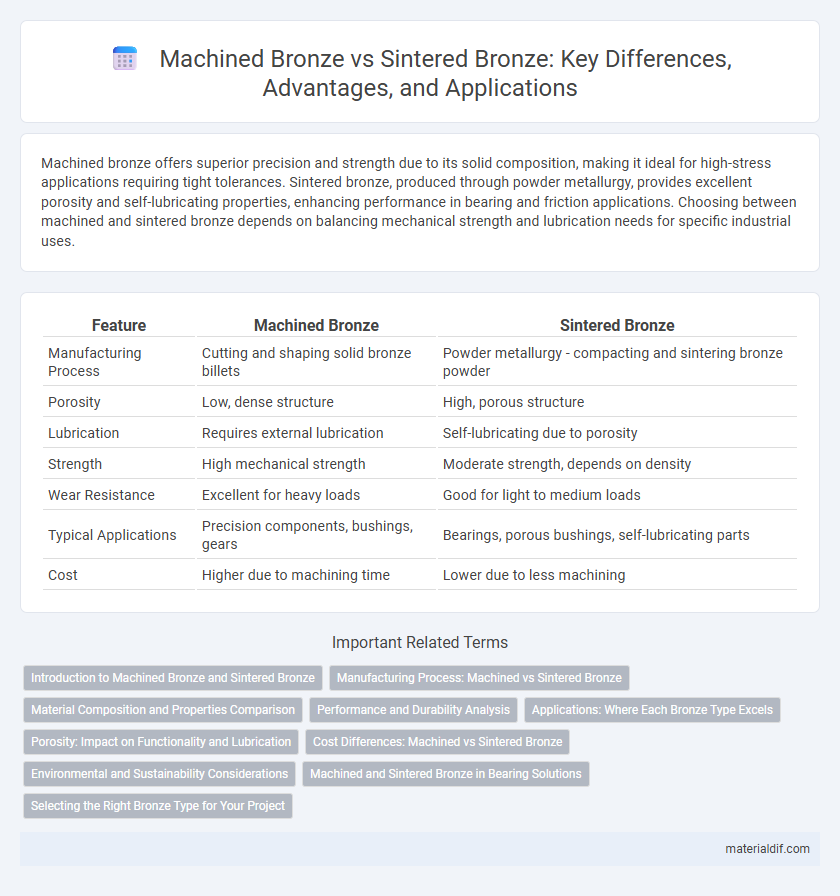

| Feature | Machined Bronze | Sintered Bronze |

|---|---|---|

| Manufacturing Process | Cutting and shaping solid bronze billets | Powder metallurgy - compacting and sintering bronze powder |

| Porosity | Low, dense structure | High, porous structure |

| Lubrication | Requires external lubrication | Self-lubricating due to porosity |

| Strength | High mechanical strength | Moderate strength, depends on density |

| Wear Resistance | Excellent for heavy loads | Good for light to medium loads |

| Typical Applications | Precision components, bushings, gears | Bearings, porous bushings, self-lubricating parts |

| Cost | Higher due to machining time | Lower due to less machining |

Introduction to Machined Bronze and Sintered Bronze

Machined bronze is a solid metal component precisely shaped through cutting and milling processes, offering high strength and excellent dimensional accuracy for heavy-duty applications. Sintered bronze is produced by compacting and heating bronze powder, resulting in a porous structure ideal for self-lubricating bearings and friction-reducing components. Both materials provide corrosion resistance and durability, but machined bronze excels in load-bearing capacity while sintered bronze is preferred for lightweight, low-maintenance parts.

Manufacturing Process: Machined vs Sintered Bronze

Machined bronze involves cutting or shaping solid bronze billets using CNC machines or lathes, resulting in precise dimensions and smooth surface finishes ideal for high-tolerance parts. Sintered bronze is produced through powder metallurgy by compacting bronze powder under high pressure and then heating it below melting point, creating porous structures suitable for self-lubricating bearings and filters. The manufacturing process of machined bronze emphasizes accuracy and surface quality, whereas sintered bronze focuses on controlled porosity and cost-effective production.

Material Composition and Properties Comparison

Machined bronze typically consists of a dense, high-copper alloy with additives like tin, aluminum, or phosphorus, providing exceptional strength, machinability, and wear resistance suitable for precision components. Sintered bronze is produced by compressing and heating bronze powder, resulting in a porous structure that offers excellent lubrication retention, reduced friction, and self-lubricating properties ideal for bearing applications. The key differences in material composition affect properties: machined bronze boasts higher density and mechanical strength, while sintered bronze's porosity enhances lubrication and reduces maintenance needs.

Performance and Durability Analysis

Machined bronze offers superior dimensional accuracy and surface finish, enhancing its performance in high-precision applications, while sintered bronze provides excellent porosity for self-lubrication and reduced friction. In terms of durability, machined bronze components generally withstand higher mechanical stresses and longer wear cycles due to their denser structure. Sintered bronze excels in environments requiring continuous lubrication but may suffer from lower strength and increased susceptibility to deformation under heavy loads.

Applications: Where Each Bronze Type Excels

Machined bronze excels in applications requiring precise tolerances, smooth finishes, and high strength, such as bushings, gears, and custom fittings in automotive and aerospace industries. Sintered bronze is ideal for self-lubricating components like bearings and porous filters, commonly used in machinery where constant lubrication is necessary without maintenance. Both types are crucial for different operational environments--machined bronze supports high-load, precision tasks, while sintered bronze offers cost-effective, low-friction solutions in continuous use.

Porosity: Impact on Functionality and Lubrication

Machined bronze exhibits low porosity, ensuring a dense structure that provides superior strength and durability for high-load applications. Sintered bronze contains controlled porosity, which significantly enhances its self-lubricating properties by retaining lubricants within interconnected pores, reducing friction and wear. The choice between machined and sintered bronze hinges on balancing structural integrity with lubrication needs, influencing performance in bearing and sliding component designs.

Cost Differences: Machined vs Sintered Bronze

Machined bronze exhibits higher production costs due to precise CNC machining, tooling expenses, and longer manufacturing times compared to sintered bronze. Sintered bronze is produced through powder metallurgy, which reduces material waste and machining hours, making it a more cost-effective option for high-volume production. Cost differences between machined and sintered bronze primarily depend on complexity, quantity, and required mechanical properties.

Environmental and Sustainability Considerations

Machined bronze components offer durability and precision but require energy-intensive processes involving significant metal waste and higher carbon emissions. Sintered bronze, produced through powder metallurgy, uses less raw material and generates minimal waste, resulting in a lower environmental footprint and enhanced resource efficiency. Choosing sintered bronze supports sustainability goals by reducing energy consumption and promoting recyclable material use in manufacturing.

Machined and Sintered Bronze in Bearing Solutions

Machined bronze bearings offer high precision and durability due to their solid, dense structure, making them ideal for heavy-load applications and environments requiring superior wear resistance. Sintered bronze bearings, produced through powder metallurgy, provide excellent lubrication retention and self-lubricating properties, reducing maintenance needs in lower-load or continuous operation scenarios. Selecting between machined and sintered bronze bearings depends on specific bearing performance requirements, load capacity, and maintenance preferences in industrial applications.

Selecting the Right Bronze Type for Your Project

Machined bronze offers precise dimensions and a smooth surface finish ideal for applications requiring tight tolerances and high strength, such as custom gears and bearing components. Sintered bronze provides excellent porosity and self-lubricating properties, making it suitable for bushings and parts needing low friction under moderate loads. Choosing between machined and sintered bronze depends on your project's performance demands, cost constraints, and the required mechanical and thermal properties.

Machined Bronze vs Sintered Bronze Infographic

materialdif.com

materialdif.com